Multi-spiral-belt recovery high-pressure cleaner

A high-pressure cleaning and transmission rod technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as low efficiency, and achieve the effect of keeping clean, easy installation and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

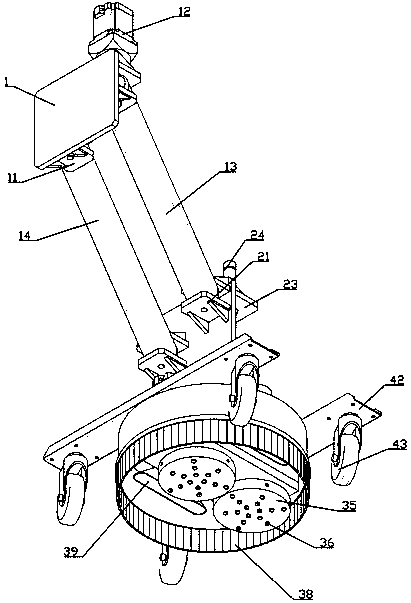

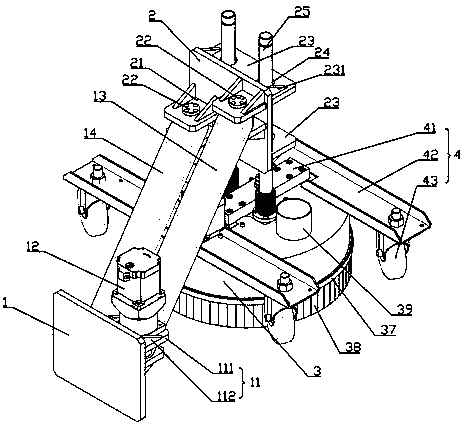

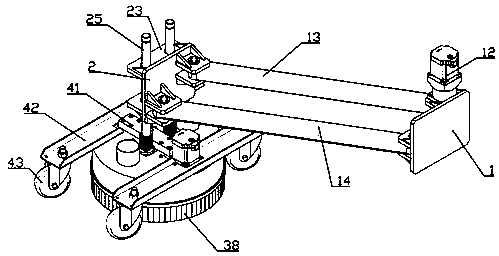

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the multi-rotary belt recovery high-pressure cleaner of the present invention includes a mounting plate 1, and the mounting plate 1 is connected with two brackets 11, and the bracket 11 on the upper side is equipped with a geared motor 12, and the power output end of the geared motor 12 is connected with a transmission rod 13. The support 11 on the lower side is connected with the auxiliary rod 14. The structure of the transmission rod 13 and the auxiliary rod 14 is the same. 21. The mounting base 21 is connected with a pin shaft 22 matching the transmission rod 13, and the other side of the mounting frame 2 is connected with two symmetrical mounting platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com