Cotton thread spring forming equipment

A technology of forming equipment and cotton thread, which is applied in the direction of making springs from threads, wire processing, textiles and papermaking, etc. Fitting, high machining accuracy, and achieving precise control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055]A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

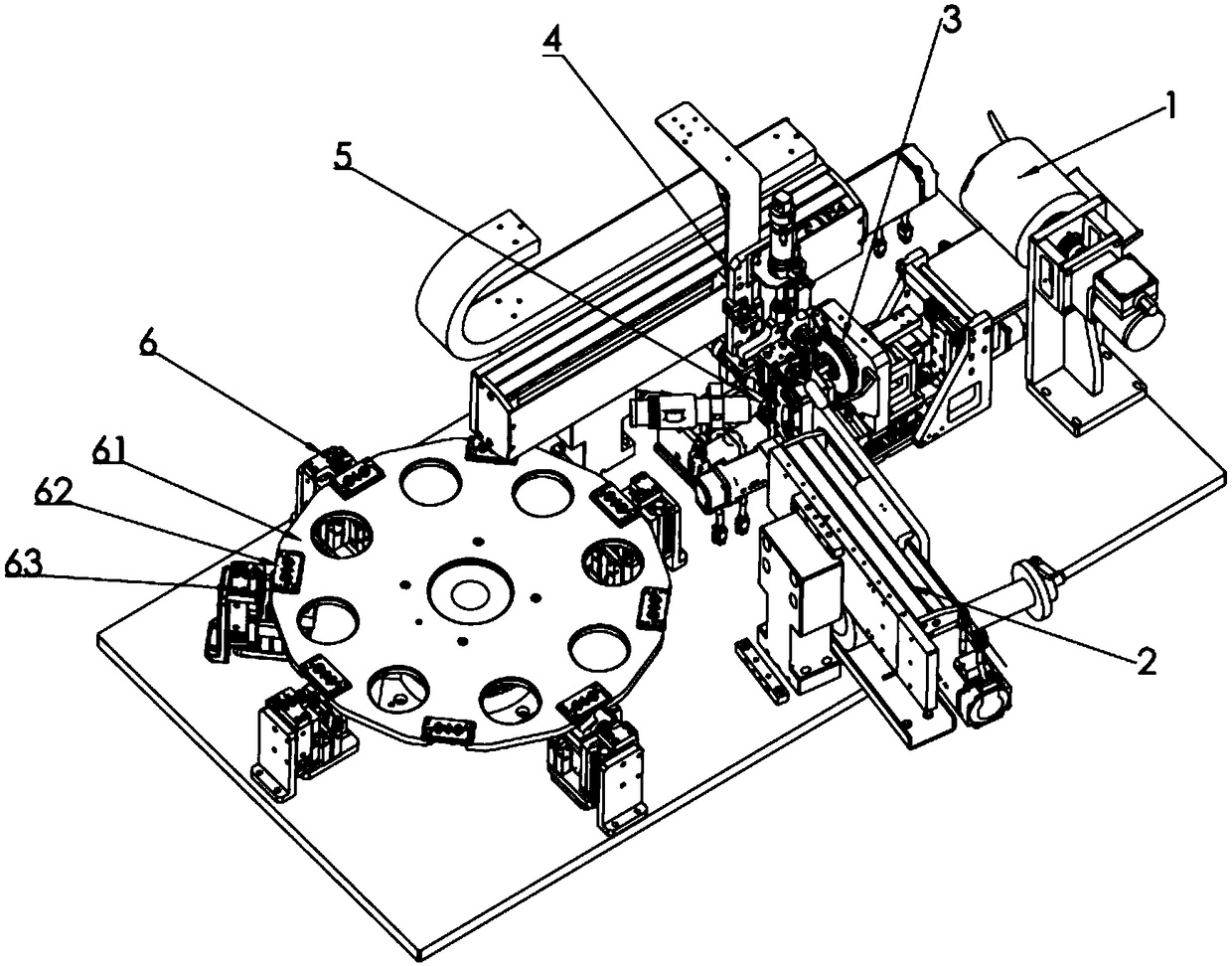

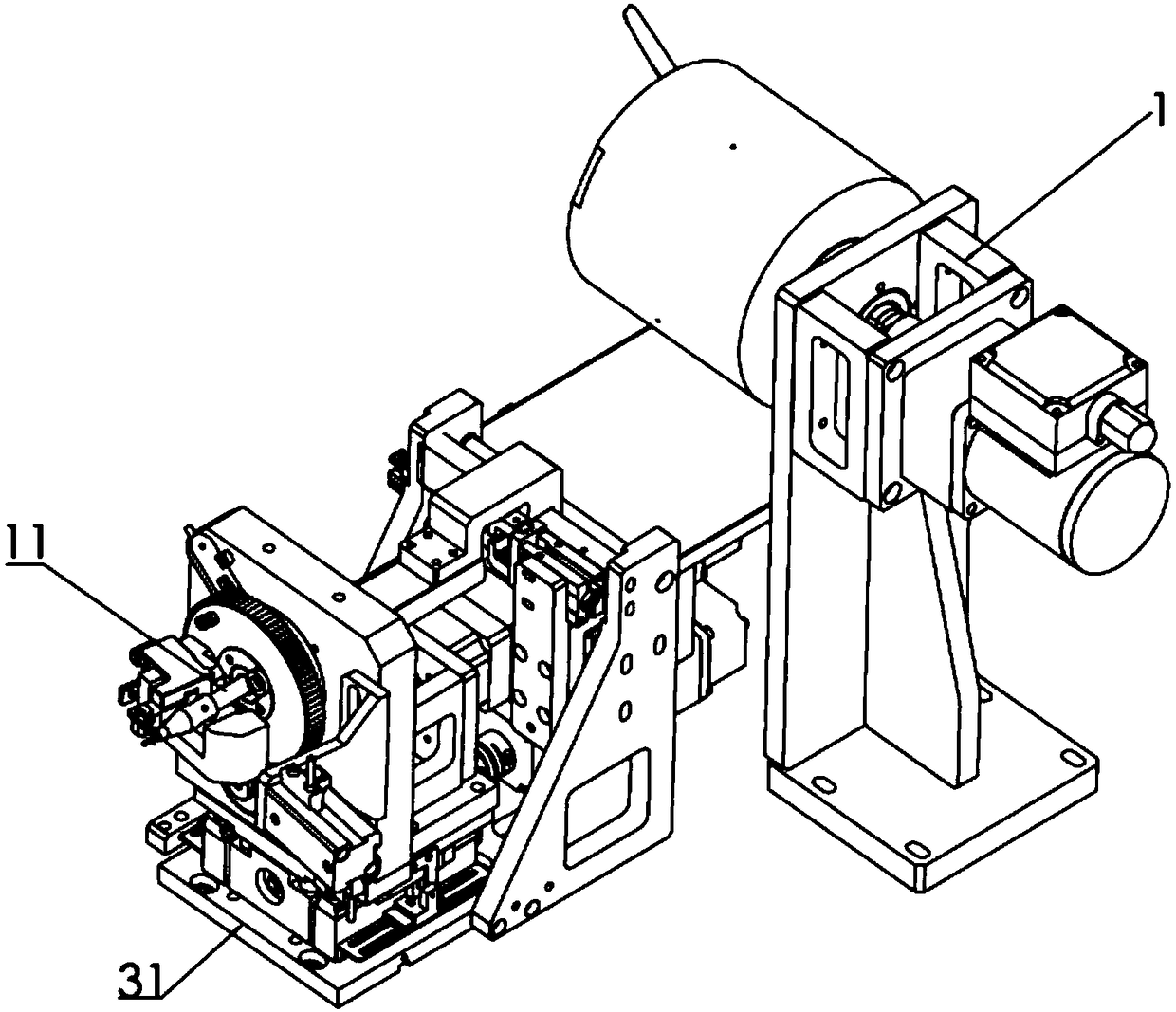

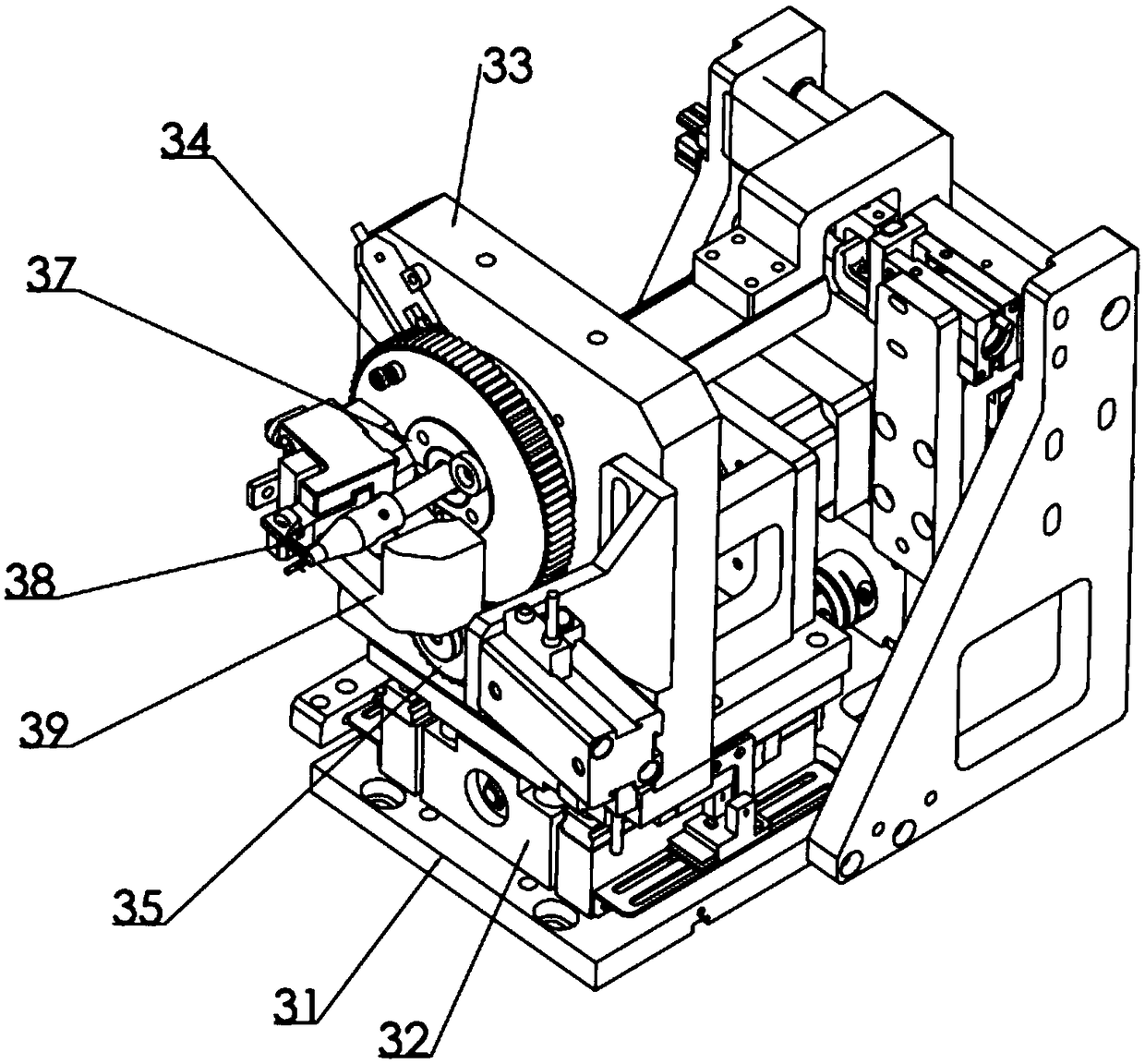

[0056] refer to Figure 1-10 , is a cotton thread spring forming device according to the present invention, comprising a wire feeding mechanism 1, a wire feeding mechanism 2, a wire winding mechanism 3, a handling mechanism 4, a cutting mechanism 5 and a carrier assembly 6, and the wire winding mechanism The metal wire conveyed by the wire feeding mechanism is spirally formed, and the conveying mechanism assembles and conveys the formed metal wire and cotton thread. It is characterized in that: the wire winding mechanism is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com