A kind of storage method of aerobic granular sludge

A technology of aerobic granular sludge and storage method, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as damage to cell structure, instability, etc. The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

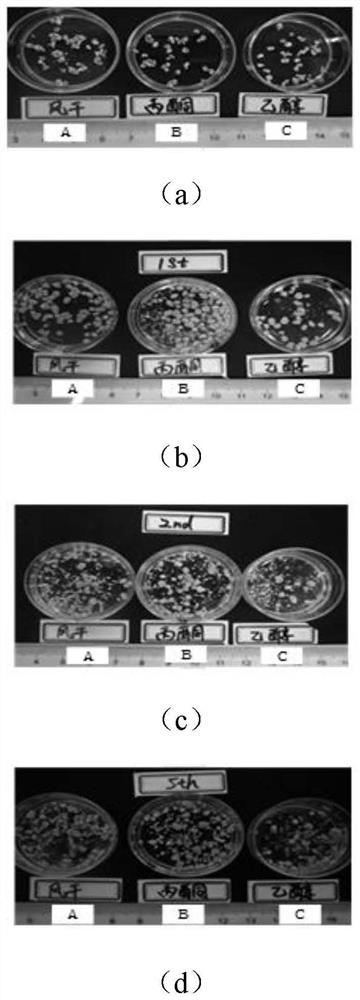

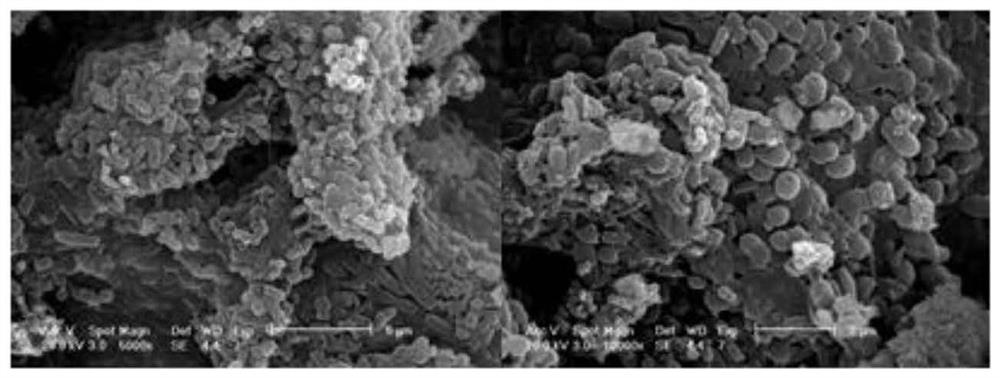

[0051] The storage method of the aerobic granular sludge of the present embodiment comprises the following steps:

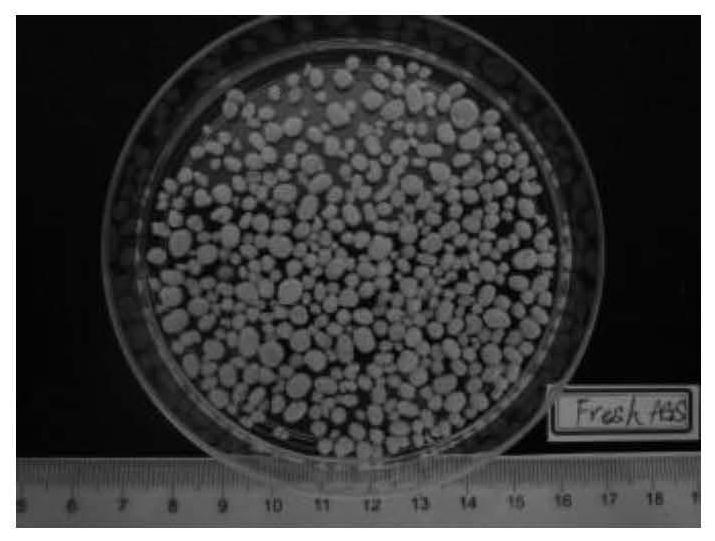

[0052] 1) After the fresh aerobic granular sludge (AGS) is completely settled, remove the supernatant, wash it twice with still water, and then transfer it to an aqueous solution of acetone with a mass concentration of 15%. Shake well under conditions for 1.5 hours, let stand for 8 minutes, and select complete AGS;

[0053] 2) Transfer the AGS obtained in step 1) to an aqueous solution of acetone with a mass concentration of 55%, shake it for 2 hours at a speed of 40 rpm, and shake it at 29±1° C., and let it stand for 4 minutes to select the complete AGS;

[0054] 3) Transfer the AGS obtained in step 2) to an aqueous acetone solution with a mass concentration of 85%, shake it evenly for 2 hours under the condition of a shaking table with a rotation speed of 40 rpm and 29±1° C., and let it stand for 5 minutes to select the complete AGS;

[0055] 4) Transfer the A...

Embodiment 2

[0058] The storage method of the aerobic granular sludge of the present embodiment comprises the following steps:

[0059] 1) After the fresh aerobic granular sludge (AGS) is completely settled, remove the supernatant, wash it with static water for 3 times, and then transfer it to an aqueous solution of acetone with a mass concentration of 20%. Shake well for 2 hours under the same conditions, let it stand for 5 minutes, and select the complete AGS;

[0060] 2) Transfer the AGS obtained in step 1) to an aqueous acetone solution with a mass concentration of 60%, shake it evenly for 5 hours at a rotating speed of 50 rpm and a shaker at 29±1° C., let it stand for 5 minutes, and select the complete AGS;

[0061] 3) Transfer the AGS obtained in step 2) to an aqueous acetone solution with a mass concentration of 80%, shake it evenly for 2 hours under the condition of a shaking table at a rotation speed of 50 rpm and 29±1° C., and let it stand for 5 minutes to select the complete AGS...

Embodiment 3

[0065] The storage method of the aerobic granular sludge of the present embodiment comprises the following steps:

[0066] 1) After the fresh aerobic granular sludge (AGS) is completely settled, remove the supernatant, wash it with static water for 3 times, and then transfer it to an aqueous solution of acetone with a mass concentration of 20%. Shake well for 2.5 hours under the same conditions, let it stand for 8 minutes, and select the complete AGS;

[0067] 2) Transfer the AGS obtained in step 1) to an aqueous solution of acetone with a mass concentration of 70%, shake it evenly for 2.5 hours under the condition of a shaker at a rotation speed of 60 rpm and 29±1° C., let it stand for 8 minutes, and select the complete AGS;

[0068] 3) Transfer the AGS obtained in step 2) to an aqueous solution of acetone with a mass concentration of 80%, shake it evenly for 1.5 hours at a speed of 40 rpm and a shaker at 29±1°C, and let it stand for 5 minutes to select the complete AGS;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com