Planetary roller screw transmission mechanism capable of achieving self-adaptive temperature control

A technology of planetary roller and transmission mechanism, applied in the direction of transmission, transmission parts, mechanical equipment, etc., can solve the problems affecting the service life of planetary roller screw transmission mechanism, thermal deformation of planetary roller screw transmission mechanism, Column screw drive mechanism damage and other problems, to achieve the effect of easy installation, good self-adaptation, and lower temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

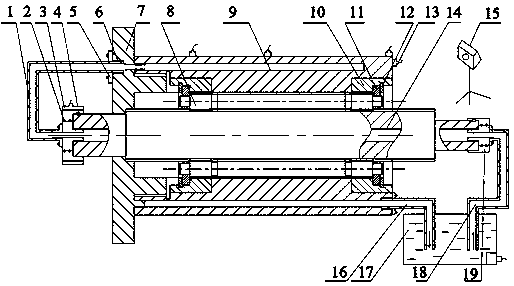

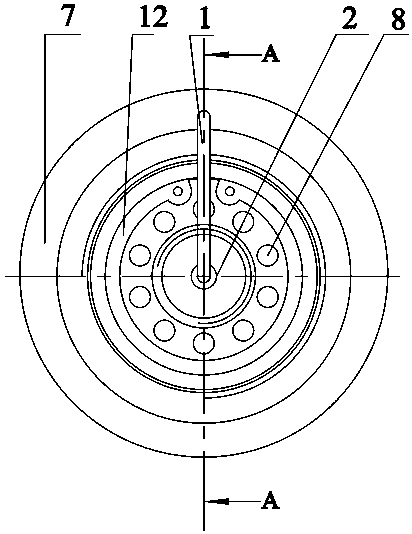

[0020] see Figure 1-4 , this embodiment includes a nut 9, the two ends of the nut 9 are provided with an inner ring gear 10 that is screwed and docked with it, and one end of the nut 9 is provided with an end cover 7 that is screwed and matched with it, and the inside of the nut 9 There are several rollers 8 arranged in a circular array, and the two ends of each roller 8 are processed with straight teeth, which mesh with the inner ring gear 10 installed at both ends of the nut 9, and the rollers 8 pass through the cage 11 The circumference is evenly distributed around the hollow screw 14, the cage 11 is axially positioned by the retaining ring 12, the roller 8 is provided with an external thread that engages with the hollow screw 14 and the nut 9, and the hollow screw 14 is arranged in the middle of the nut 9, and one end of the nut 9 is provided with an end cap 7 screwed to it, and the end of the hollow lead screw 14 passes through the end cap 7 and is connected to the outer...

Embodiment 2

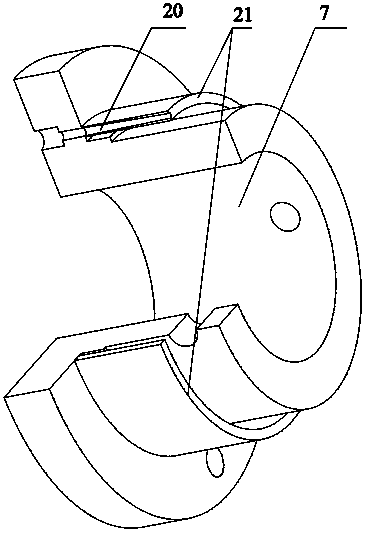

[0025] In this specific embodiment, the coolant circulating pump 17 provides power, and the coolant flows through the outlet pipe 18 through the hollow lead screw 14 to take away part of the heat generated by the lead screw, and then takes it away through the wedge-shaped hole 20 of the end cover and the annular groove 23 of the nut Part of the heat generated by the nut 9 finally flows back to the cooling liquid circulation pump 17 from the outlet through hole 24 below the nut 9 to complete the circulation of the cooling circulation system. Four magnetic temperature sensors 13 are placed on the nut 9 to pass through the magnetic temperature sensor 13 The monitored temperature changes are used to feedback and adjust the flow rate of the coolant circulation pump 17, so that the temperature can be adaptively maintained within a certain range, and when the set temperature upper limit is reached, the program will generate an alarm. And place a thermal imager 15 to monitor the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com