Channeling-blockage physical simulation experiment device and effect evaluation method

An experimental device and physical simulation technology, applied in measurement devices, mechanical devices, instruments, etc., can solve problems such as the evaluation of no sealing effect, and achieve the effect of simple method, accurate simulation effect, and reduced interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

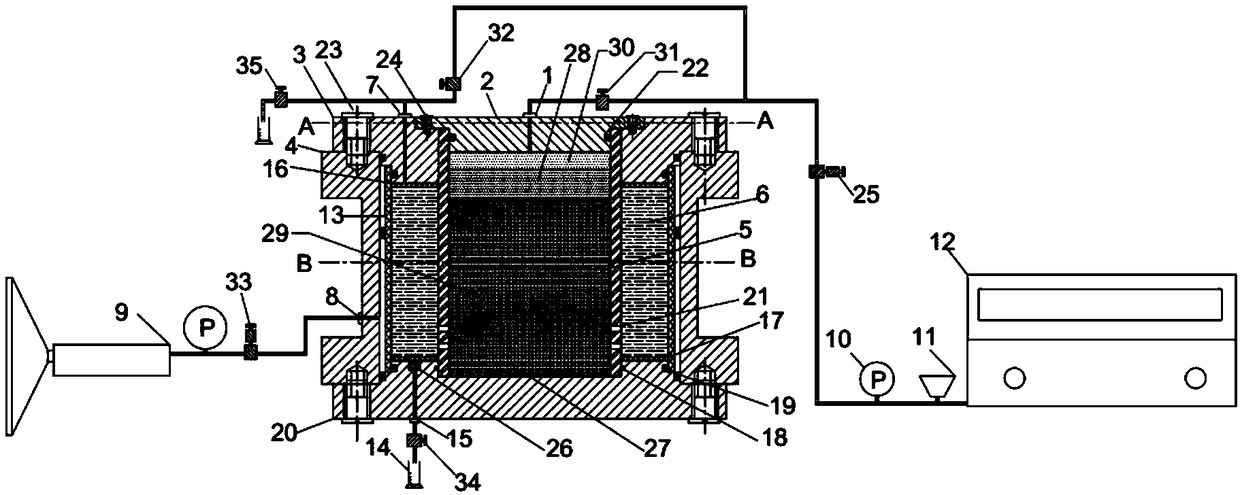

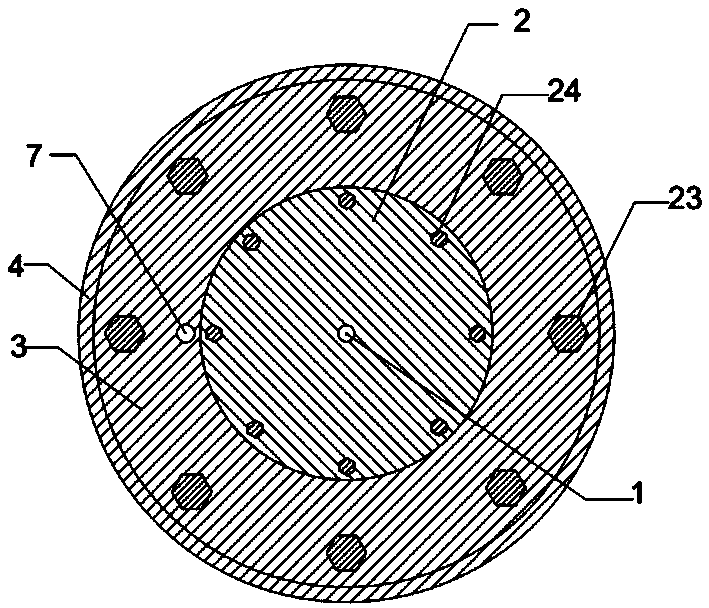

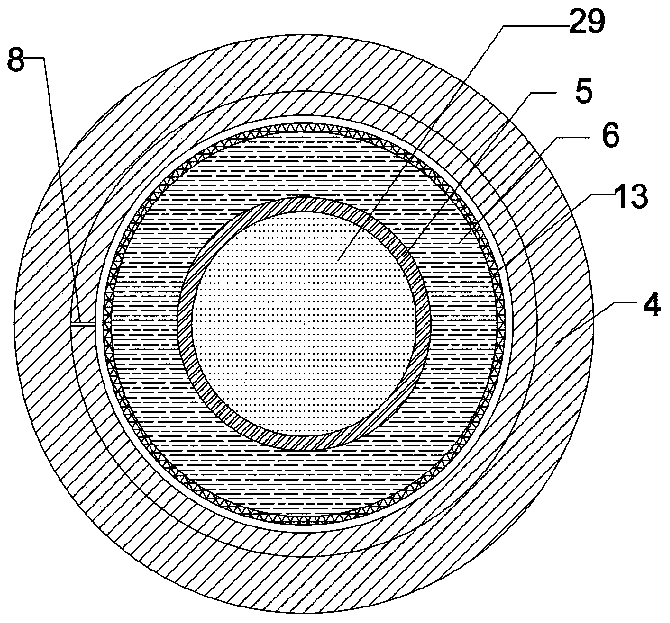

[0042] Such as Figure 1~3 As shown, it is a schematic structural diagram of a physical simulation experiment device for sealing channeling according to an embodiment of the present invention. The device includes a kettle body 4 and a casing 5, and a ring-pressed rubber sleeve 13 is arranged between the kettle body 4 and the casing 5. An annular cavity is formed between the ring pressure rubber sleeve 13 and the casing 5, and the cement ring 6 is inside the cavity; the upper and lower ends of the kettle body 4 are respectively provided with an upper flange 3 and a lower flange 20. The upper flange 3 and the lower flange 20 are respectively provided with a liquid injection hole 7 and a liquid outlet hole 15. The liquid outlet hole 15 is provided with a fifth switch 34 for controlling the opening and closing of the liquid outlet hole 15. The liquid injection hole 7 and the liquid outlet hole 15 are all connected with the inside of the kettle body 4; the upper flange 3 is an annu...

Embodiment 2

[0058] The method of using this device to evaluate the effect of blocking channeling:

[0059] It is mainly evaluated by comparing the permeation flow rate of the interface between casing 5 and cement before and after the sealing agent 29 is squeezed in under the same conditions, including the following steps:

[0060] (1) Measure the seepage flow Q of the cement sheath 6 and casing 5 cemented sealing system before the sealing experiment 1 , the specific steps are: ① Install the lower flange 20 first, then put the sealing system with channeling channels in the cemented interface between the cement sheath 6 and the casing 5, install the upper flange 3 and the small flange 2, and open the second Three switches 32 connect the output pipeline of the advection pump 12 to the liquid injection hole 7, and close the second switch 31 and the sixth switch 35; ②According to the needs of the experiment, use the hand pump 9 to pressurize the ring rubber sleeve 13 to cement and casing 5 Ad...

Embodiment 3

[0067] Use the above-mentioned device to simulate the sealing system method in which channeling channels exist at the interface between the cement sheath and the casing:

[0068] (1) Adhere the asphalt strips with fixed size and shape to the specified position on the outer wall of the casing 5, and the asphalt strips are connected to each other and connected to the lower hole of the casing;

[0069] (2) Install the lower flange 20 after evenly applying a high-temperature-resistant release agent on the inner wall of the ring pressure rubber sleeve 13, and put the lower flange 20 on the surface of the lower annular rubber sealing plate 17 that is in contact with the cement. Then screw the plug into the perforation hole 21 at the lower part of the casing 5 and put it in, pour the prepared cement slurry into the cavity between the casing 5 and the ring pressure rubber sleeve 13, and adjust the constant temperature control The device is maintained at a certain temperature for a cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com