Ultrasonic device suitable for long-time treatment of magnesium alloy melt

A magnesium alloy, long-term technology, applied in the field of metal smelting and ingot casting, can solve the problems of difficulty in normal operation of the transducer, high smelting temperature of magnesium alloy, low melt processing efficiency, etc., so as to improve the service life and prolong the service life. , the effect of blocking heat conduction and radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 An ultrasonic device suitable for processing magnesium alloy melts for a long time

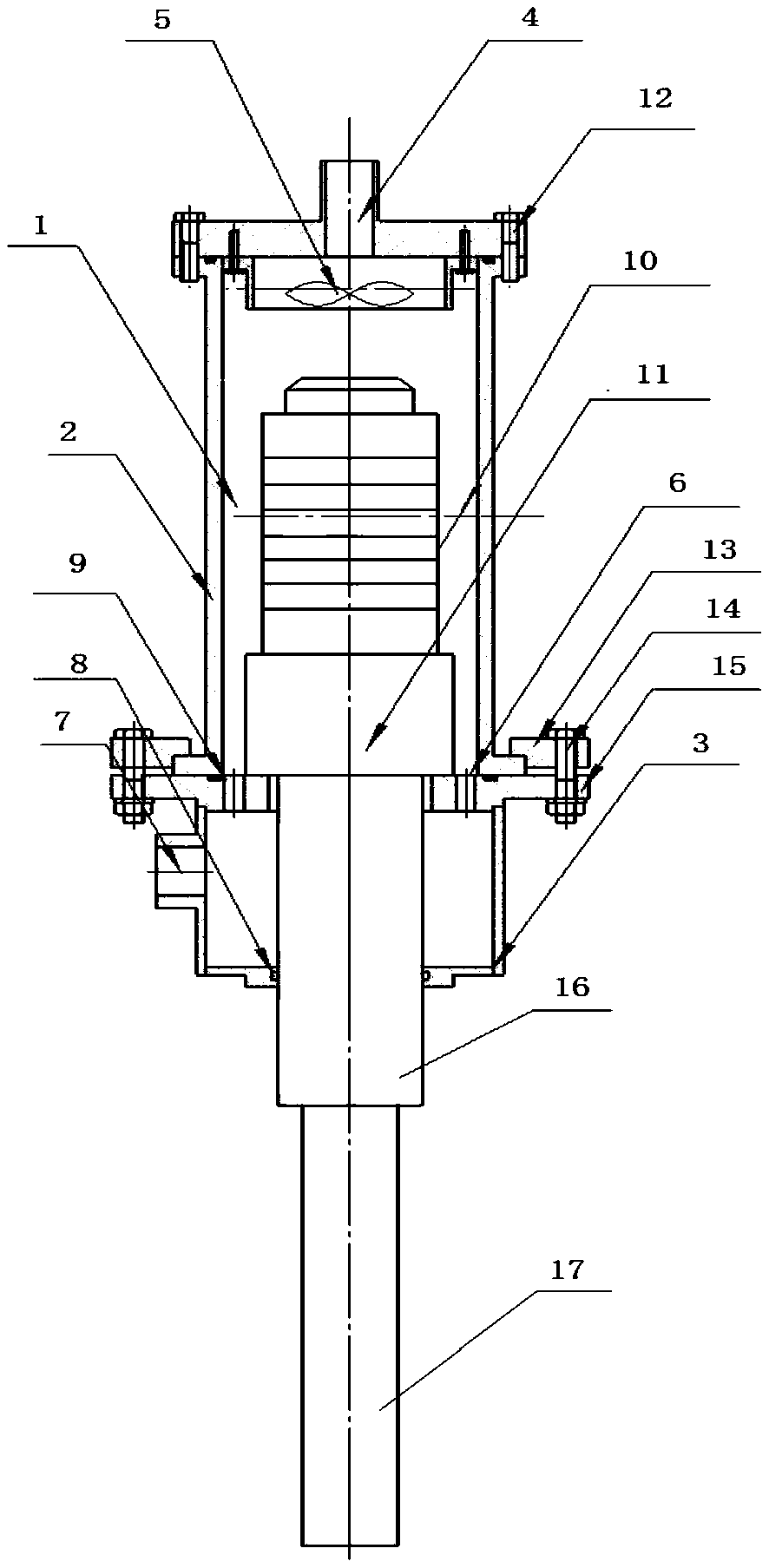

[0032] The ultrasonic device of the magnesium alloy melt of the present invention comprises a controller and a probe, such as figure 1 shown. The probe includes a transducer 10, a horn 11, a connecting rod 16 and a tool head 17 in turn, and also includes a cooling device, such as figure 2 shown.

[0033] The probe is placed in a cooling device when in use; the cooling device includes a casing and a cooling chamber 1 formed by the casing; the cooling chamber is divided into an upper cooling chamber 2 and a lower cooling chamber 3; the upper and lower cooling chambers pass through The through hole 6 is connected; the top of the upper cooling chamber 2 has an air inlet 4; the lower part of the lower cooling chamber 2 has an air outlet 4; a fan 5 is arranged below the air inlet 4.

[0034] The air inlet 4 and the air outlet 7, in order to ensure the cooling effect, the greater...

Embodiment 2

[0037] Example 2 An ultrasonic device suitable for processing magnesium alloy melts for a long time

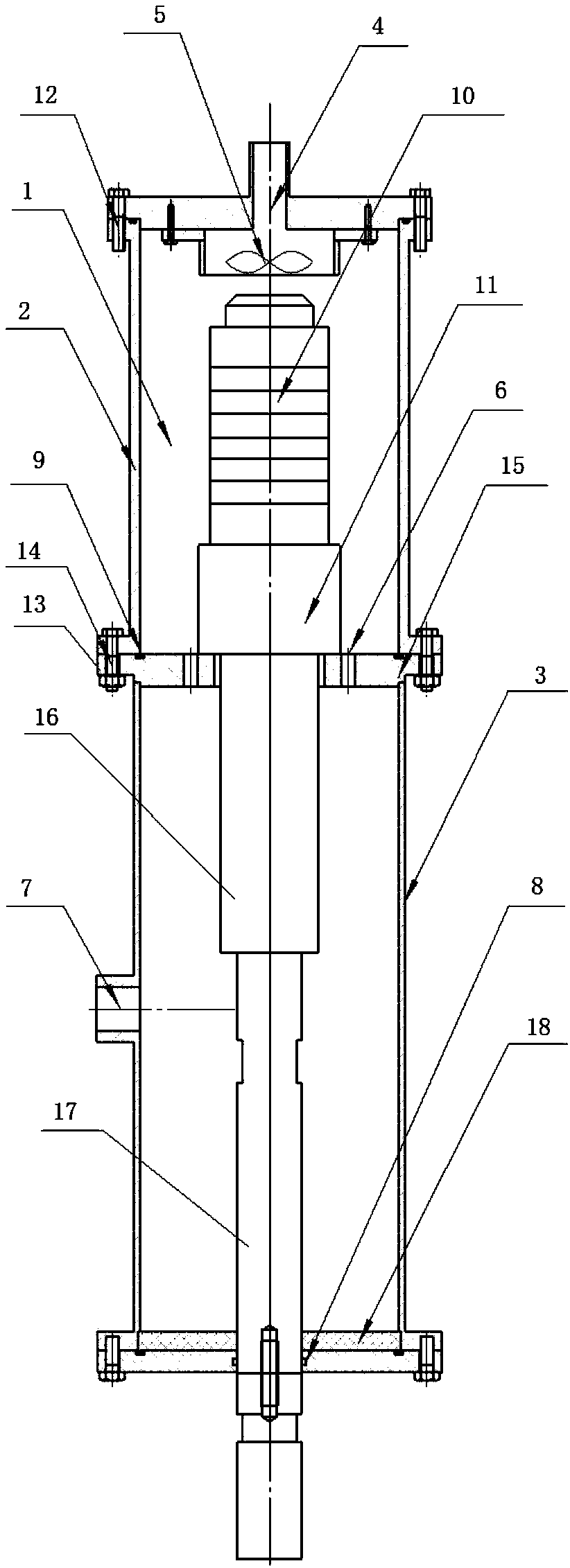

[0038] The ultrasonic device of the magnesium alloy melt of the present invention comprises a controller and a probe, such as figure 1 shown. The probe includes a transducer 10, a horn 11, a connecting rod 16 and a tool head 17 in turn, and also includes a cooling device, such as image 3 shown.

[0039] The probe is placed in a cooling device when in use; the cooling device includes a casing and a cooling chamber 1 formed by the casing; the cooling chamber is divided into an upper cooling chamber 2 and a lower cooling chamber 3; the upper and lower cooling chambers pass through The through hole 6 is connected; the top of the upper cooling chamber 2 has an air inlet 4; the lower part of the lower cooling chamber 2 has an air outlet 4; a fan 5 is arranged below the air inlet 4.

[0040] The air inlet 4 and the air outlet 7, in order to ensure the cooling effect, the greater ...

Embodiment 3

[0044] During die casting of AZ80, the melt needs to be treated before the ingot is solidified. Due to the short time, the ultrasonic device shown in Example 1 can be selected for treatment, and air can be introduced for cooling. It is recommended that the melt temperature be lowered to about 610°C for ultrasonic treatment. The treatment time varies according to the size of the ingot, generally about 2-5 minutes. During treatment, the ultrasonic probe should be inserted into the melt 15mm below the liquid surface, and then cooled rapidly.

[0045]Practice has shown that ultrasonic treatment is carried out in AZ80 magnesium alloy melt, and more gas may be mixed in the magnesium alloy melt, which will help to form a large number of cavitation nuclei, which will be conducive to the generation of cavitation bubbles. The cavitation bubble breaks away from the stable zone and collapses to release a large amount of energy, which is enough to break up the growing dendrites. Part of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com