Sky wheel type steel wire rope ring automatic welding device

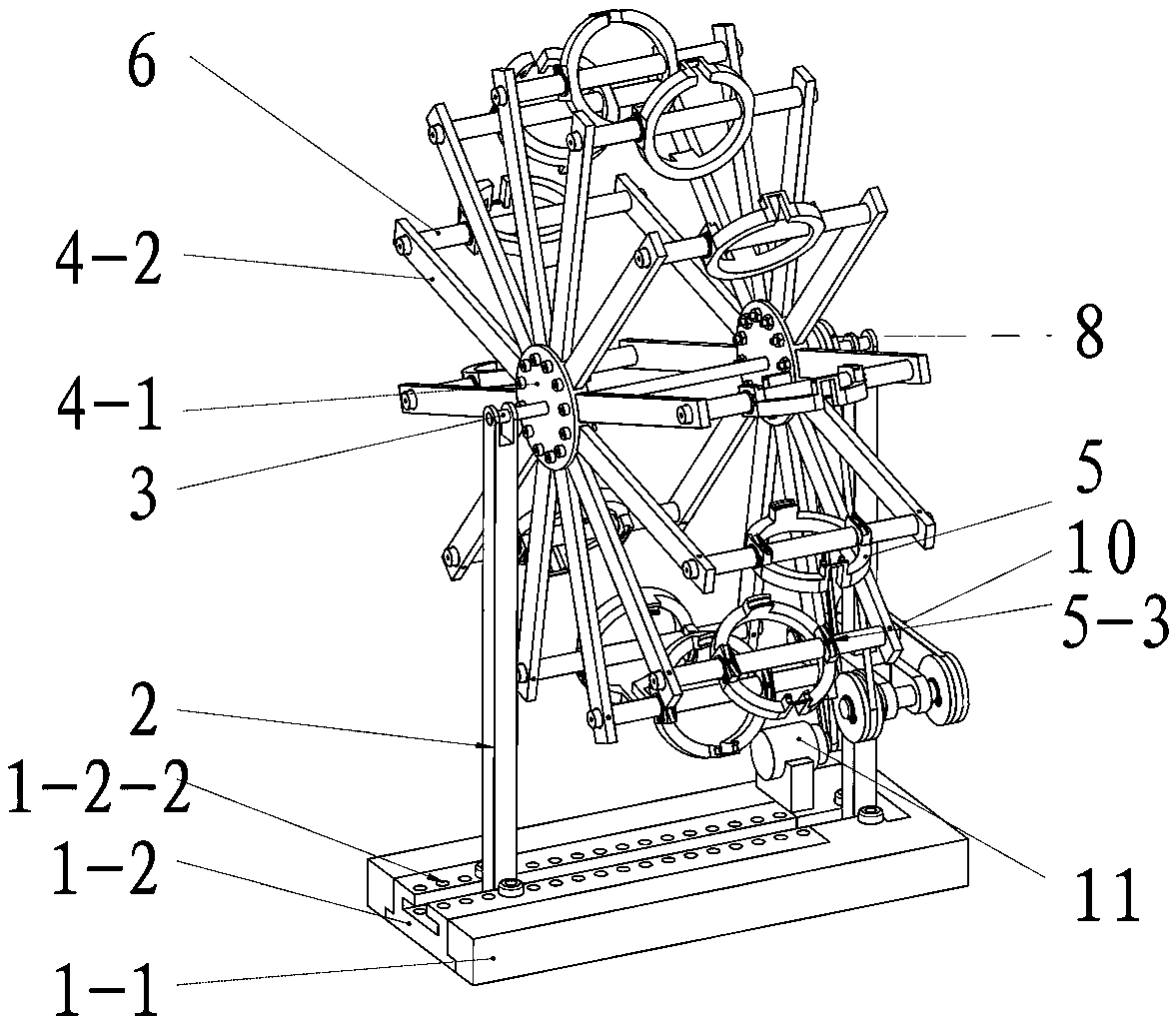

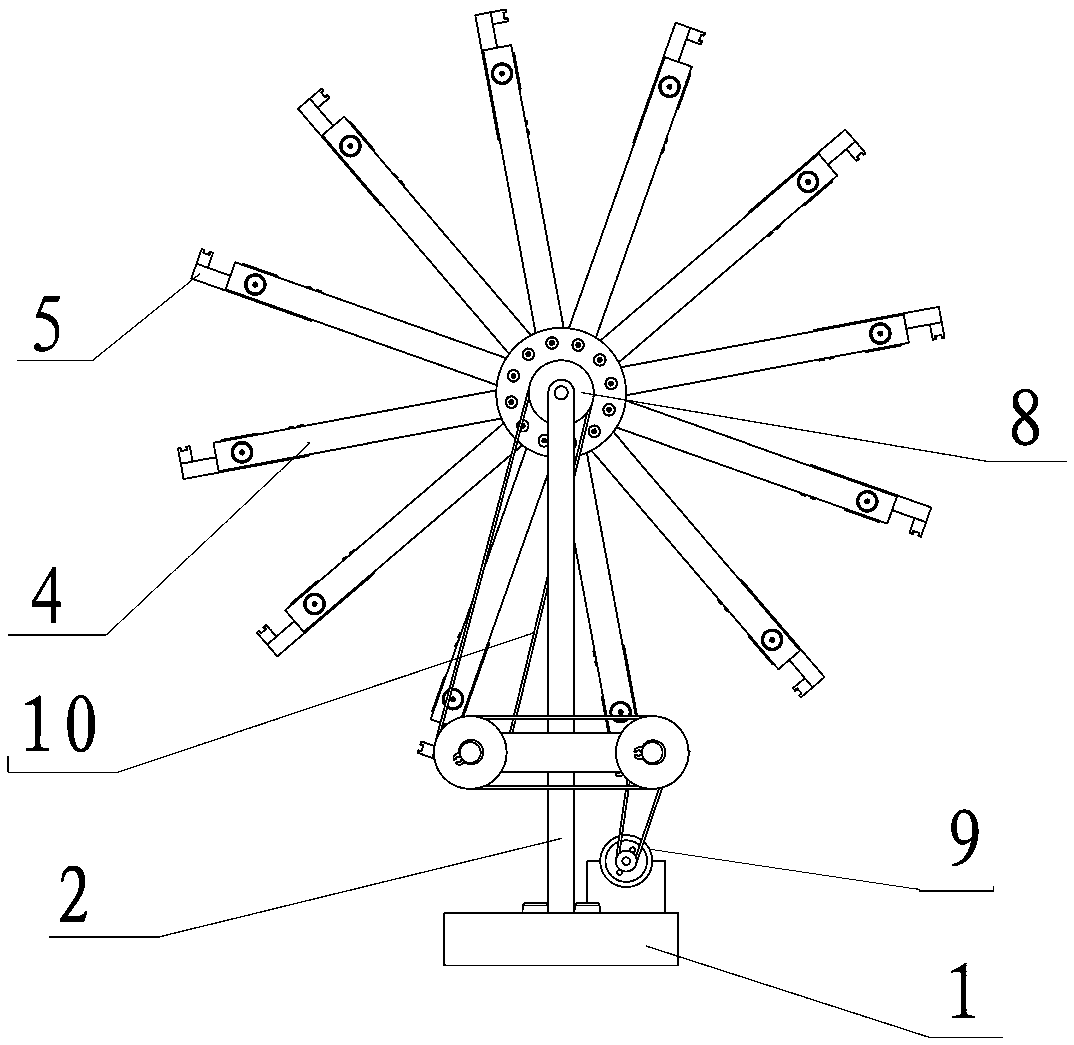

An automatic welding, Ferris wheel type technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of inability to adapt to large-scale production, limited number of wire rope loops, and incompatibility with robot operation, etc., to improve quality and Ease of operation, good welding quality, good roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

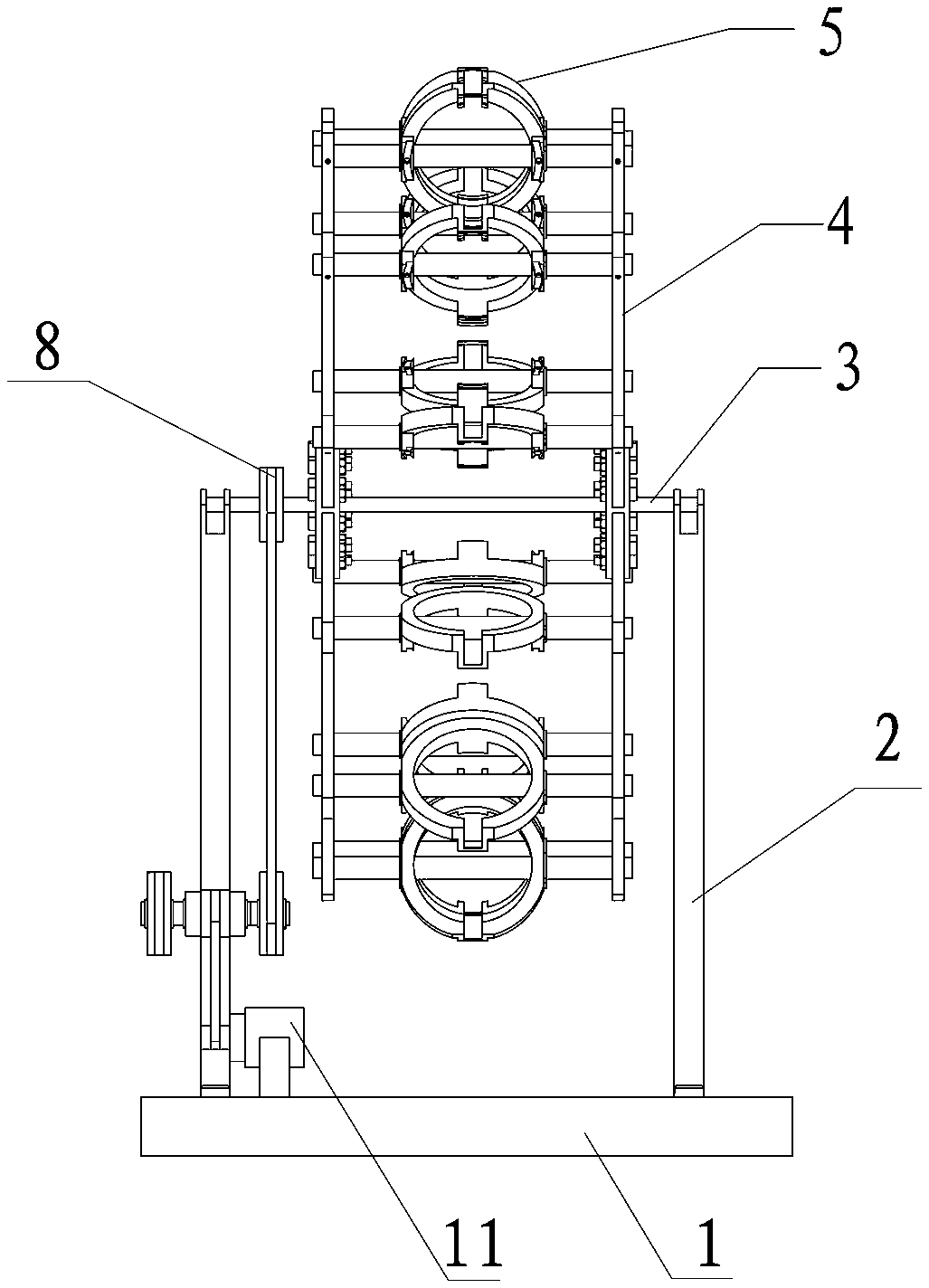

Embodiment 1

[0042] A specific structure of the wire rope ring positioning fixture 5 is as follows: comprising an annular base 5-1, the annular base 5-1 is radially pierced on the fixed shaft 6 and fixed by a screw and the shaft with a circlip, the annular base 5 -1 is fixed with a plurality of spaced positioning projections 5-2 by bolts, the top of the positioning projections is provided with a groove 5-3 that matches the arc of the wire rope ring, and a plurality of spaced grooves 5-3 form an annular The outline constitutes the positioning groove of the steel wire rope ring, and the groove at the top of one of the positioning projections 5-2 is the welding part of the steel wire rope ring joint, and the welding part extends downwards along the groove 5-3 to be provided with an empty slot.

Embodiment 2

[0044] The difference from Embodiment 1 is that a transitional connection block 7 is added, and the transitional connection block 7 is fixed on the fixed shaft 6 by screws and a shaft circlip, and then the ring base 5-1 is fixed on the transitional connection block by screws 7, other installation structures on the annular base 5-1 are the same as in Embodiment 1, so that it is convenient to disassemble and replace the wire rope ring positioning fixture 5.

Embodiment 3

[0046] On the basis of Embodiment 1, an upwardly extending protrusion 12 is added between the spaced positioning protrusions 5-2 on the annular base 5-1, and the end of the protrusion is radially inward or Outward extension is provided with the wire rope loop processing part 13 that adapts to other models, is provided with the height difference that avoids mutual interference between this processing part and the spaced positioning projection 5-2, is provided with the steel wire rope ring of this type on this processing part. The groove 2 14 adapted to the circular arc, the annular contour formed by a plurality of spaced grooves 14 constitutes the second wire rope ring positioning groove on the tooling, and the groove 2 14 on one of the raised parts is the welding part of the wire rope ring joint , the welding part extends downward along the groove 2 14 and is provided with an empty slot; the additional structure of this part is a separate integral part, which is detachably moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com