A casting mold for anti-swirl nozzle

A technology for casting molds and spouts, which is applied in the direction of molds, manufacturing tools, mold auxiliary parts, etc., and can solve problems such as critical personal safety, wasting time, and affecting production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

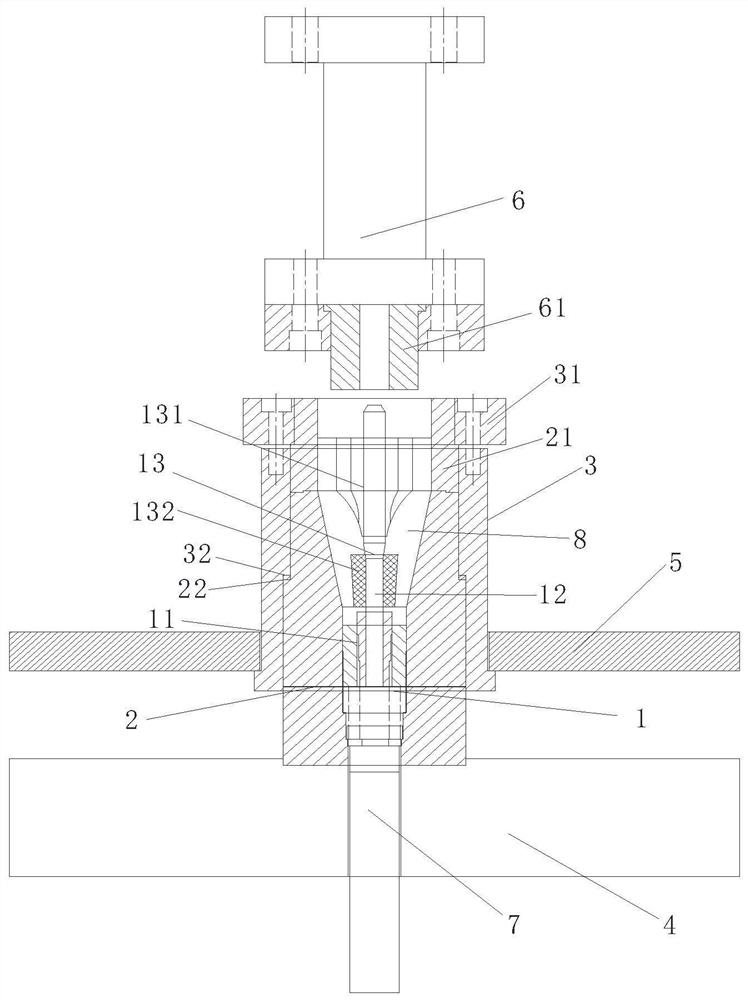

[0025] like figure 1 As shown, an anti-swirl nozzle casting mold, the anti-swirl nozzle casting mold includes a mold body 1, a main mold cover 2, a protective cover 3, a base 4, a floating platform 5 that can move up and down, a main cylinder 6 and a top Cylinder 7, the main mold sleeve 2 is socketed outside the mold body 1, and a material layer 8 is formed between the two, and the protective sleeve 3 is sleeved outside the main mold sleeve 2 and fixed with the floating platform 5 Connected, the bottom of the main mold cover 2 is fixedly connected with the base 4, the lower end of the mold body 1 is connected with the jack cylinder 7, and its upper end is movably connected with the main cylinder 6.

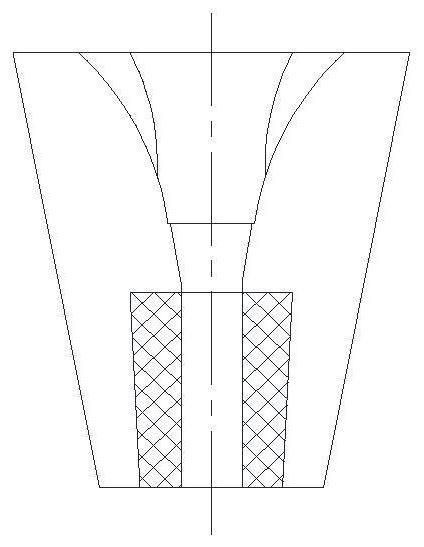

[0026] In practical application, the mold body 1 includes a core base 11, a core rod 12 and a core 13, the bottom of the core rod 12 is movably connected to the core base 11, and the core base 11 is connected to the core base 13. The jack cylinder 7 is connected, and the mold cor...

Embodiment 2

[0034] A method for casting an anti-swirl nozzle, the method for casting an anti-swirl nozzle comprises the following steps:

[0035] Step S1: Proportioning raw materials and binders and granulating to obtain the required casting materials;

[0036] Specifically, it can be: mix raw materials such as corundum, quartz, graphite, alumina micropowder, etc., according to the required weight percentage, to provide preparation for the next step of granulation;

[0037] A binder is added to the powder obtained after proportioning, and granulated to meet the conditions of the required casting material in the mold molding operation. Preferably, the binder in this embodiment is phenolic resin. The casting material is in the form of mud.

[0038] Step S2: Fix the main mold cover on the base, and fix the protective cover on the floating platform;

[0039] Step S3: After splicing and forming the main body of the mold, it is connected and fixed with the top cylinder in the middle of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com