Full-automatic brake pad production device

A technology for production equipment and brake pads, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems such as safety hazards, low processing efficiency, and increased labor costs, so as to reduce labor costs and improve production efficiency. The effect of compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

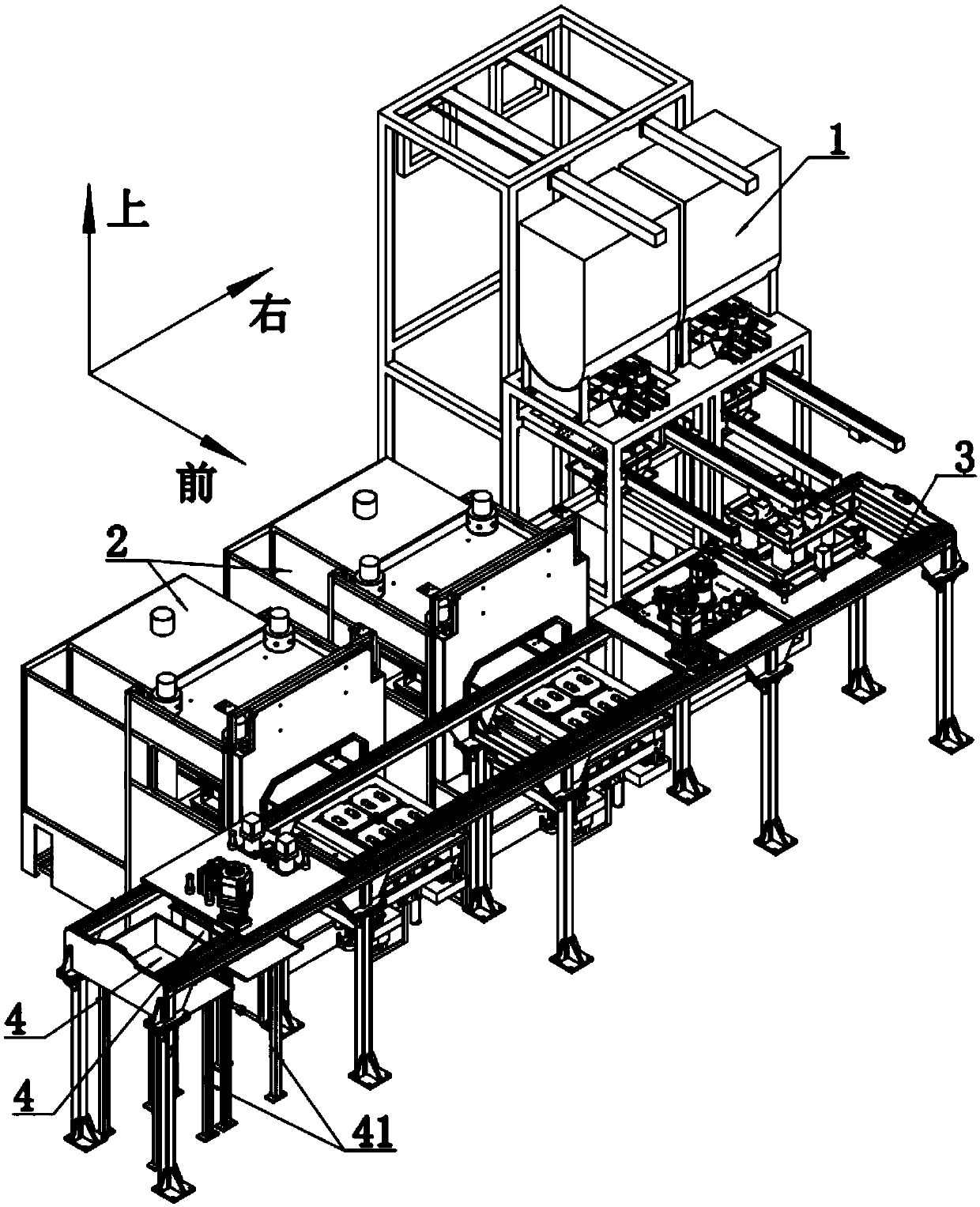

[0077] Such as figure 1 As shown, a fully automatic brake pad production equipment includes a hot press 2 , a feeding device 3 and a weighing device 1 . Wherein said hot press machine 2 is a plurality of sets, and is arranged in a line together with said weighing device 1 . The weighing device 1 is arranged at the end, and as a specific implementation, the weighing device 1 described in this embodiment is arranged at the rightmost end. The feeding device 3 is arranged on the front side of the hot press 2 and the weighing device 1 .

[0078] The middle mold unit and the lower mold unit of the heat press 2 can extend out of the fuselage of the heat press 2 . The specific structure of this heat press 2 has been disclosed in the patent No. 2015108472132, which belongs to the prior art, and will not be repeated here.

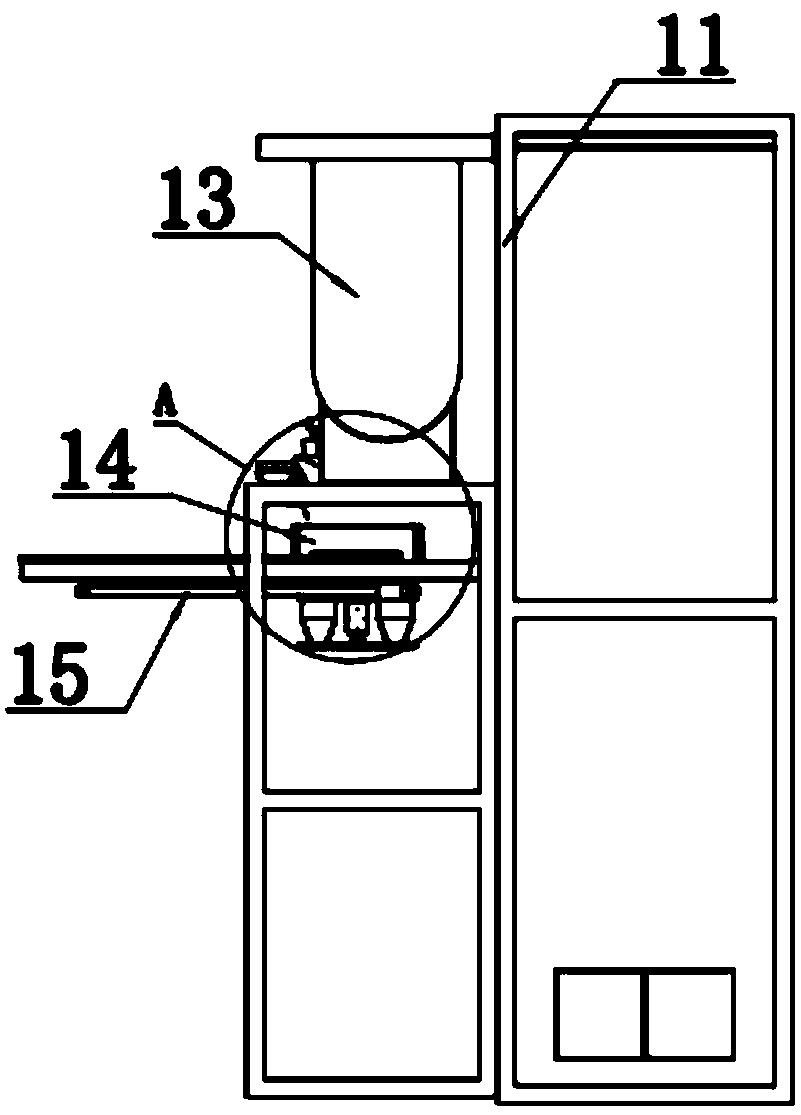

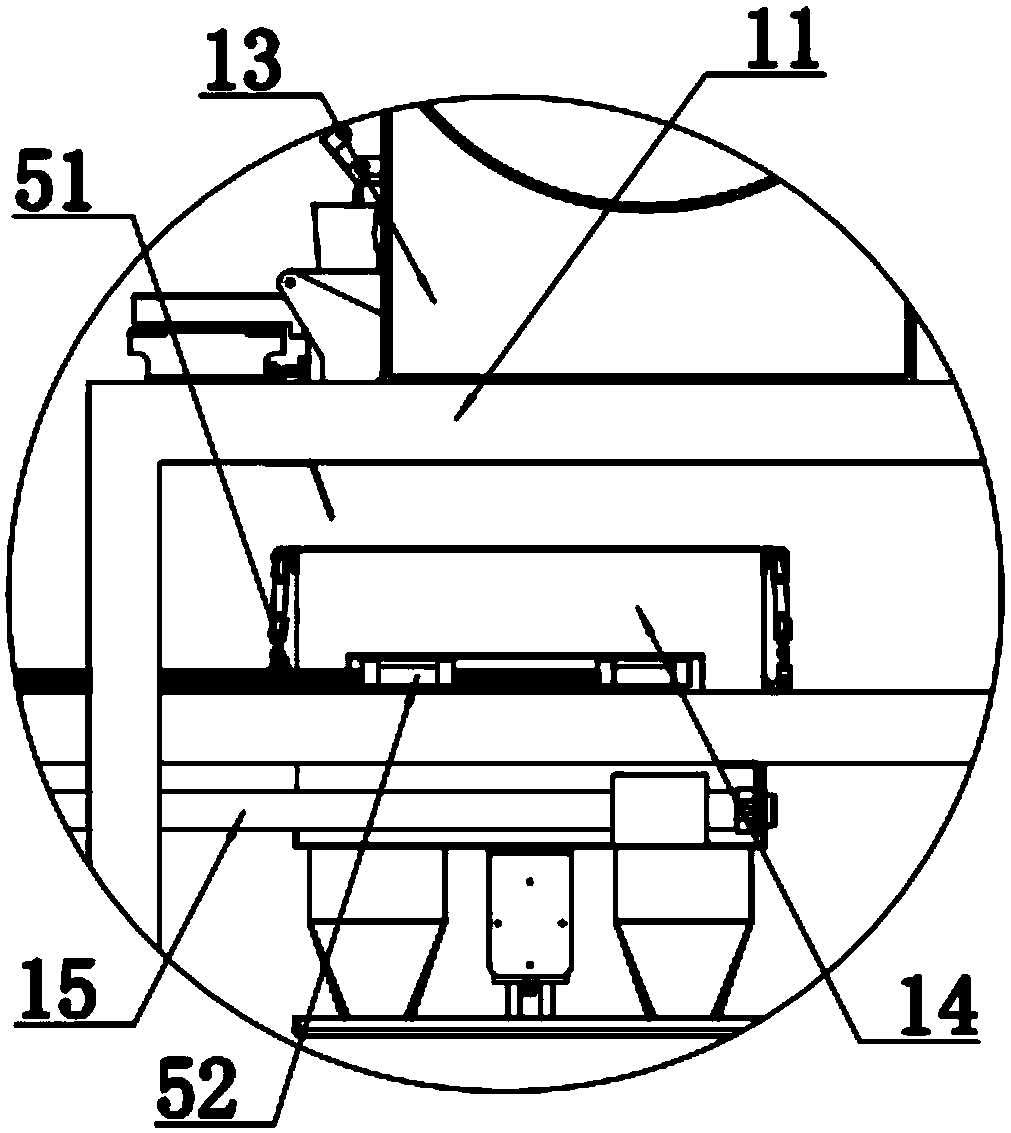

[0079] Such as figure 2 with Figure 4 As shown, the weighing device 1 includes a weighing frame body 11, and two sets of weighing systems are arranged side by...

Embodiment 2

[0129] The plug 3576 is not provided with diversion groove 35761, and the conical surface of the plug 3576 is provided with a through hole communicating with the blind hole, and when the conical surface of the plug 3576 is compressed When on the steps of the first hole section and the second hole section, the through hole is located in the second hole section, and the rest of the structure is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com