Membrane flattening device

A technology of membrane materials and installation grooves, which is applied in the field of machinery and equipment, can solve problems such as undetectable coil defects, uneven thickness of membrane materials, and wavy lines on the drum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

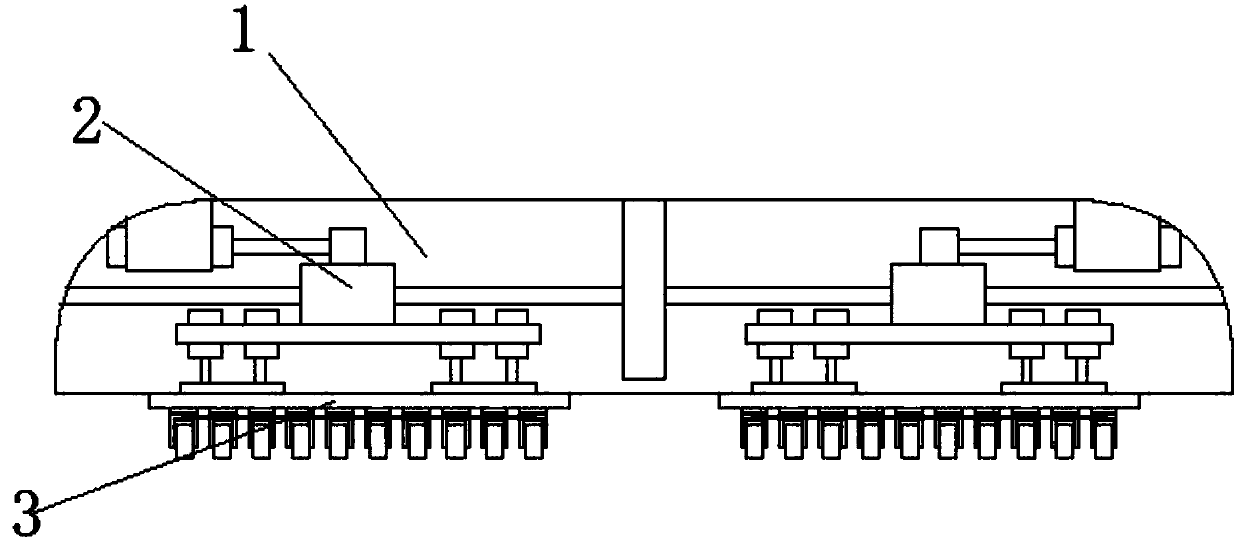

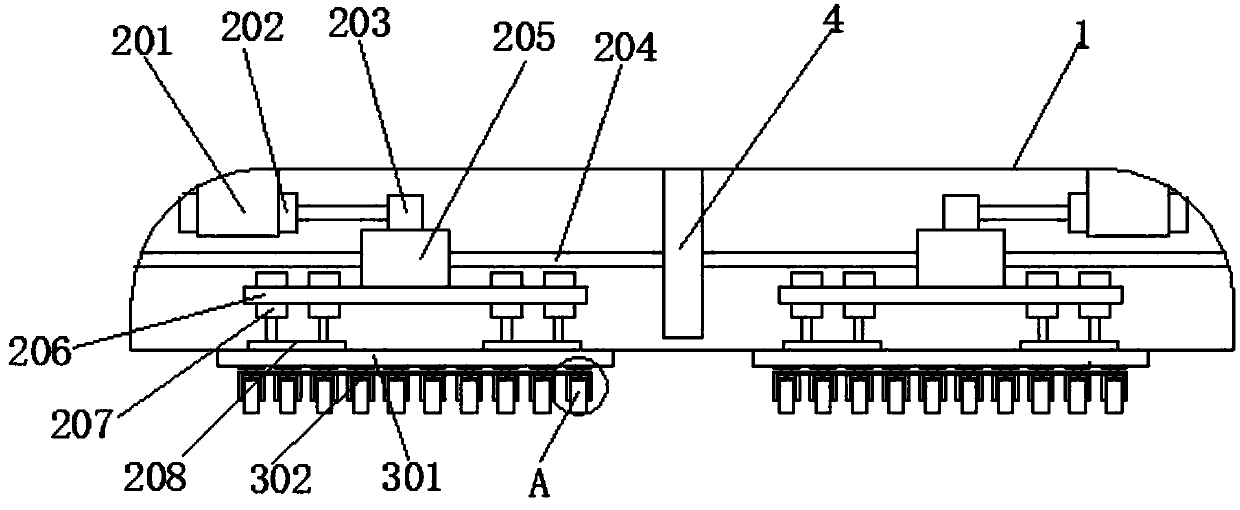

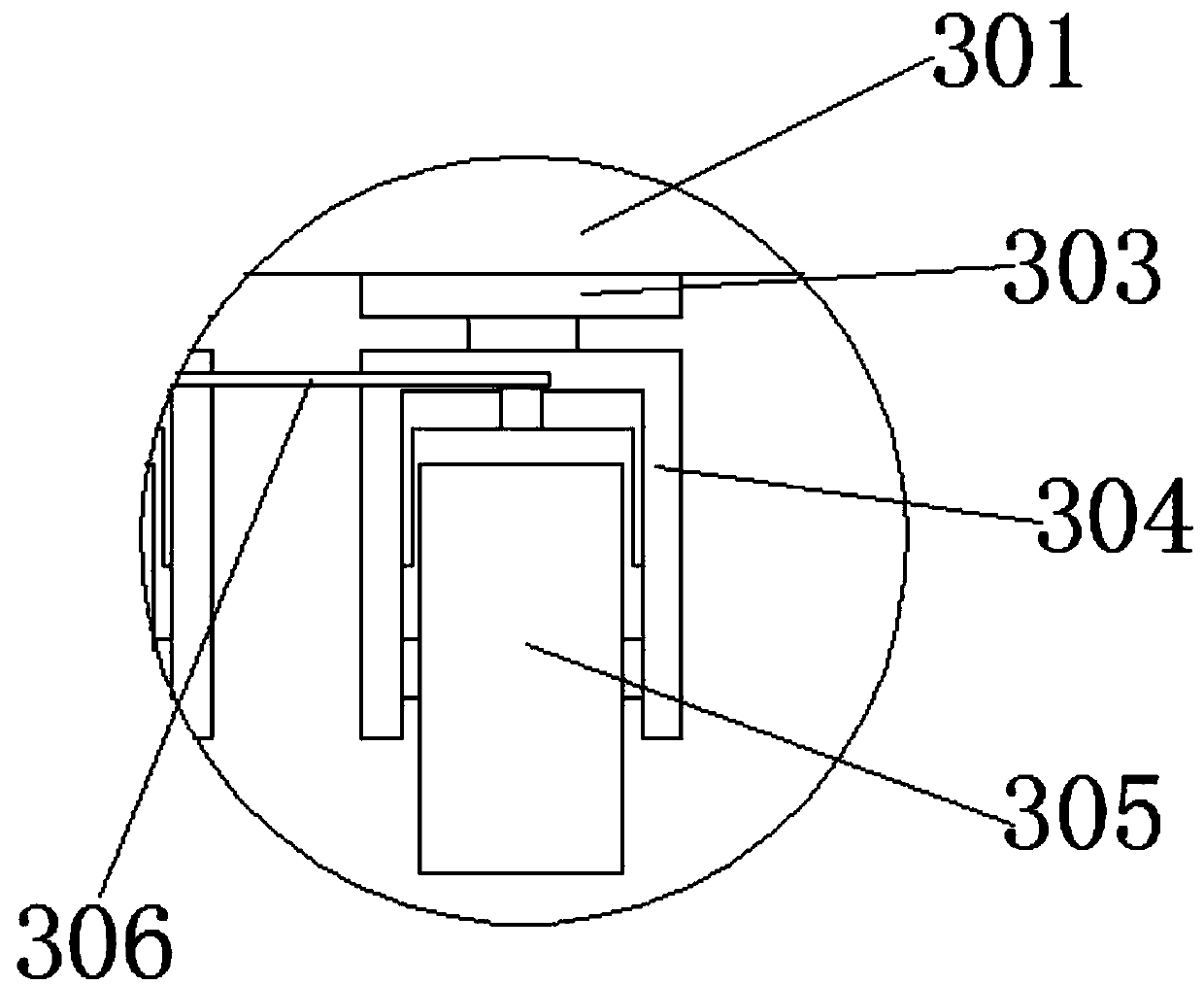

[0030] combined with Figure 1-3 As shown, a membrane material smoothing mechanism includes a housing 1, a transmission mechanism 2, and a smoothing mechanism 3. The housing 1 is provided with a lower opening, and the transmission mechanism 2 is installed inside the housing 1. The smoothing mechanism 3 and the transmission mechanism 2 is driven and connected, and the movement direction of the transmission mechanism 2 is perpendicular to the direction of the film material. A partition 4 is provided in the middle of the casing 1, and the transmission mechanism 2 includes a cylinder fixing seat 201 installed on the inner upper part of the casing 1, a traverse guide rail 204 installed in the casing 1, and a traverse cylinder is installed in the cylinder fixing seat 201. 202, the front end of the piston rod of the traversing cylinder 202 is connected with a traversing connecting block 203, the traversing guide rail 204 is provided with a traversing movable block 205, the traversing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com