Elevator Counterweight

An elevator and counterweight technology, applied in the field of elevator traction systems, can solve problems such as wear and tear of heavy guide shoes, and achieve the effects of prolonging the maintenance and replacement cycle, flexible change, and easy to manufacture and install.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

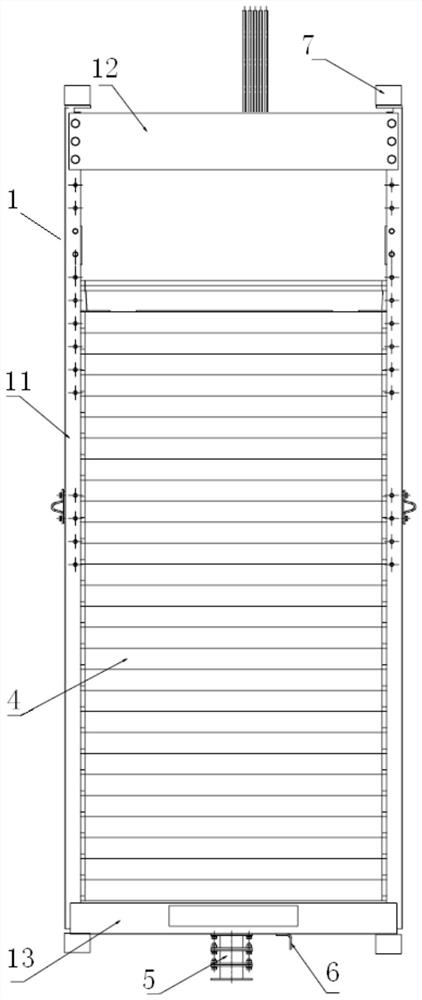

[0028] Such as figure 1 As shown, the elevator counterweight device includes a counterweight frame 1, a counterweight block 4, at least two pairs of counterweight guide shoes 7 and compensation chains / cables;

[0029] The counterweight guide shoes 7 are respectively installed on the counterweight frame 1 for moving up and down along the counterweight guide rail;

[0030] The counterweight 4 is fixedly installed in the counterweight frame 1;

[0031] The suspension wire rope is fixedly connected to the lifting point with the upper frame part 12 of the counterweight frame 1 or is connected to the lifting point through the counterweight wheel;

[0032] One end of a single compensation chain / cable or one end of two compensation chains / cables with different unit weights is suspended on the lower frame member 13 of the counterweight frame 1;

[0033] The other end of a single compensation chain / cable or the other ends of two compensation chains / cables with different unit weights a...

Embodiment 2

[0045] Based on the elevator counterweight device of Embodiment 1, the counterweight frame 1 includes two side frame members 11, an upper frame member 12 and a lower frame member 13;

[0046] The two side frame parts 11 , one upper frame part 12 and one lower frame part 13 are connected by bolts or welding to form a counterweight frame 1 .

[0047] Preferably, two pairs of counterweight guide shoes 7 are installed on the upper frame member 12 and the lower frame member 3 respectively, and move up and down along the counterweight guide rail.

[0048] Preferably, a hanger part 6 is fixed on the lower side of the lower frame part 13; one end of a single compensation chain / cable or two compensation chains / cables with different unit weights are suspended from the hanger part 6.

[0049] Preferably, a bumper bumper 5 is fixed in the middle part of the lower side of the lower frame member 13 .

[0050] Preferably, the counterweight guide shoe 7 adopts a sliding guide shoe or a rolle...

Embodiment 3

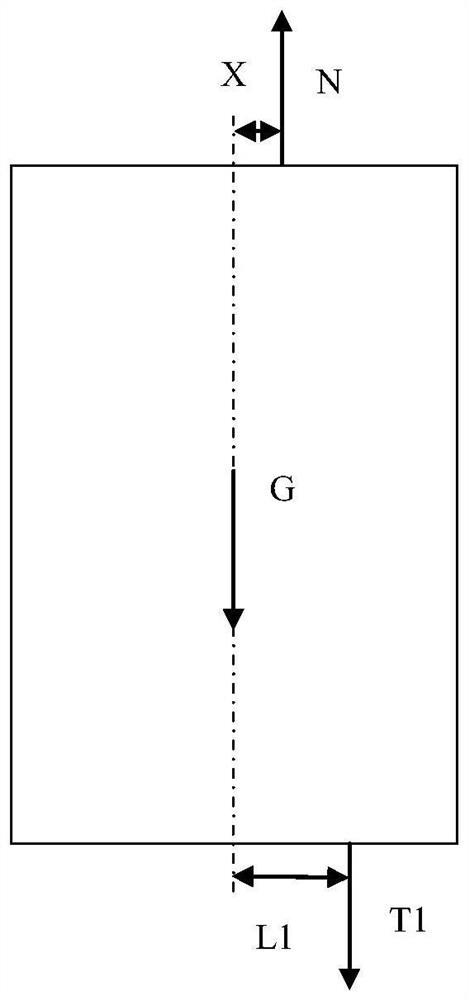

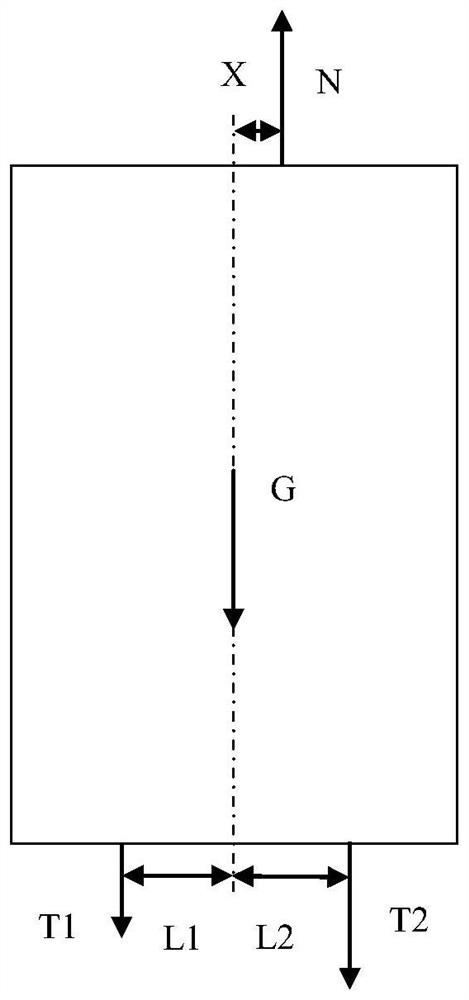

[0052] The lifting point offset elevator counterweight device with a single compensation chain / cable, the suspension point of the steel wire rope is offset X to the right of the center of gravity of the counterweight, and the compensation chain / cable is suspended on the right of the center of gravity of the counterweight. The unbalanced moment analysis of the guide shoe 7 of the heavy device is as follows: figure 2 shown.

[0053] N is the tension of the wire rope, and the corresponding moment arm X;

[0054] T1 is the tension of a single compensation chain / cable on the counterweight, and the moment arm is L1;

[0055] When NX=T1*L1, the unbalanced moment disappears;

[0056] Get X=T1*L1 / N;

[0057] Since the tension T1 of the compensation chain / cable changes during the up and down running of the elevator car, the actual value of X can be calculated according to the force at the position of 1 / 2 the lifting height.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com