Efficient anaerobic denitrification bioreactor

A bioreactor and deoxygenation technology, applied in anaerobic digestion treatment, biological water/sewage treatment, water pollutants, etc., can solve the problem of increasing the denitrification load of sewage treatment plants, increasing operating treatment costs, and affecting denitrification effects and other problems, to achieve good mass transfer effect, save investment and operation costs, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

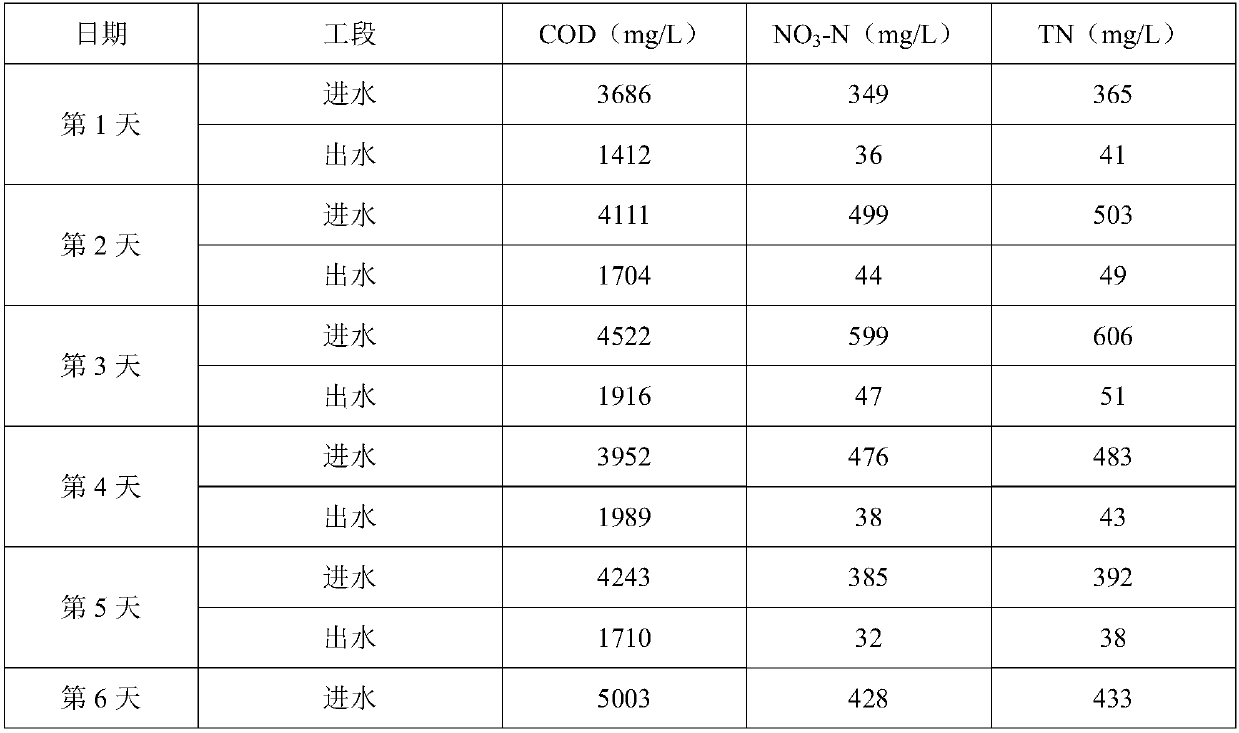

Examples

Embodiment

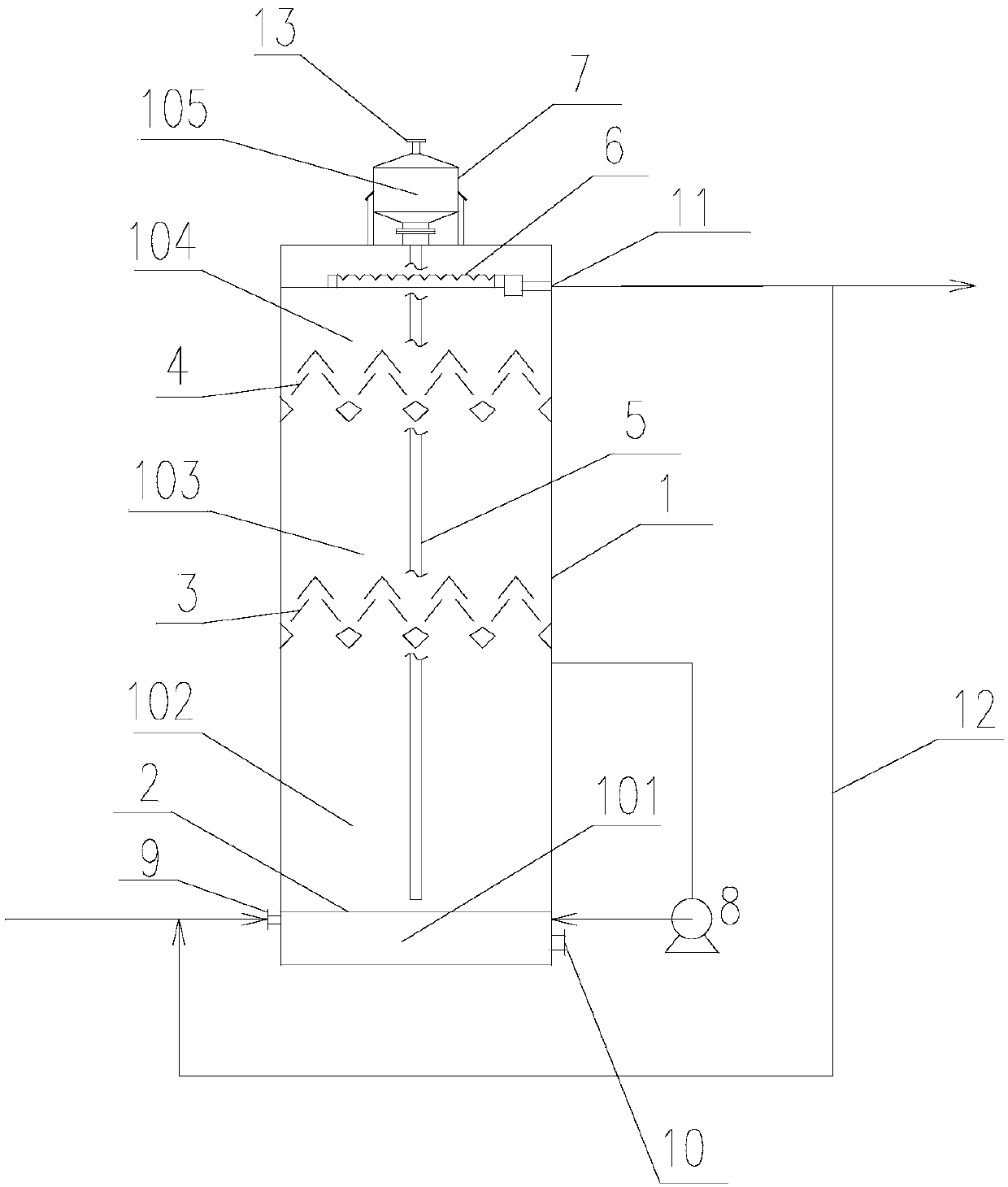

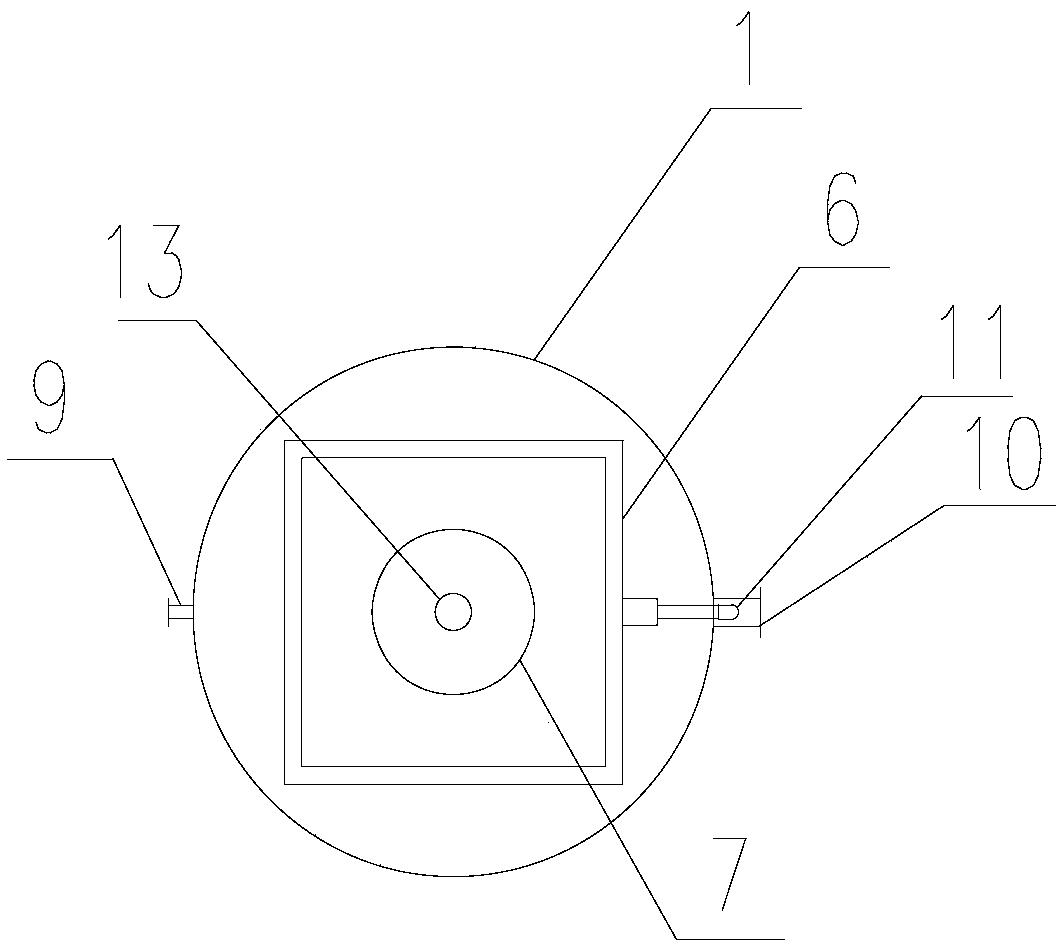

[0024] Please refer to Figure 1-Figure 2 A high-efficiency anaerobic denitrification bioreactor shown includes a tank body 1, a water distributor 2, a first-stage three-phase separator 3, a second-stage three-phase separator 4, an internal return pipe 5, and an outlet weir 6 , a gas-water separator 7, an external circulation pump 8, the first-stage three-phase separator 3 and the second-stage three-phase separator 4 are arranged in parallel and staggered, and both of them are equipped with air ducts (not shown in the figure) Shown), the air duct communicates with the gas-water separator 7.

[0025] A water outlet 11 is provided on the side wall of the tank body 1, and the interior of the tank body 1 is divided into five functions: a mixing zone 101, a nitrogen and carbon removal chamber 102, a carbon removal conversion chamber 103, a precipitation zone 104, and a gas-water separation zone 105 zone, the denitrification and carbon removal chamber 102 is located above the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com