Guide device for exhaust gas emitted by rising pipe of coke oven

A technology of guiding device and coke oven, which is applied to the discharge device of dry distillation gas, the heating of coke oven, and the heating of coke oven, etc., can solve the problems of affecting the working environment of closed greenhouses, the threat of safe production and operation of coke oven, etc. Safety and health, the effect of a good operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

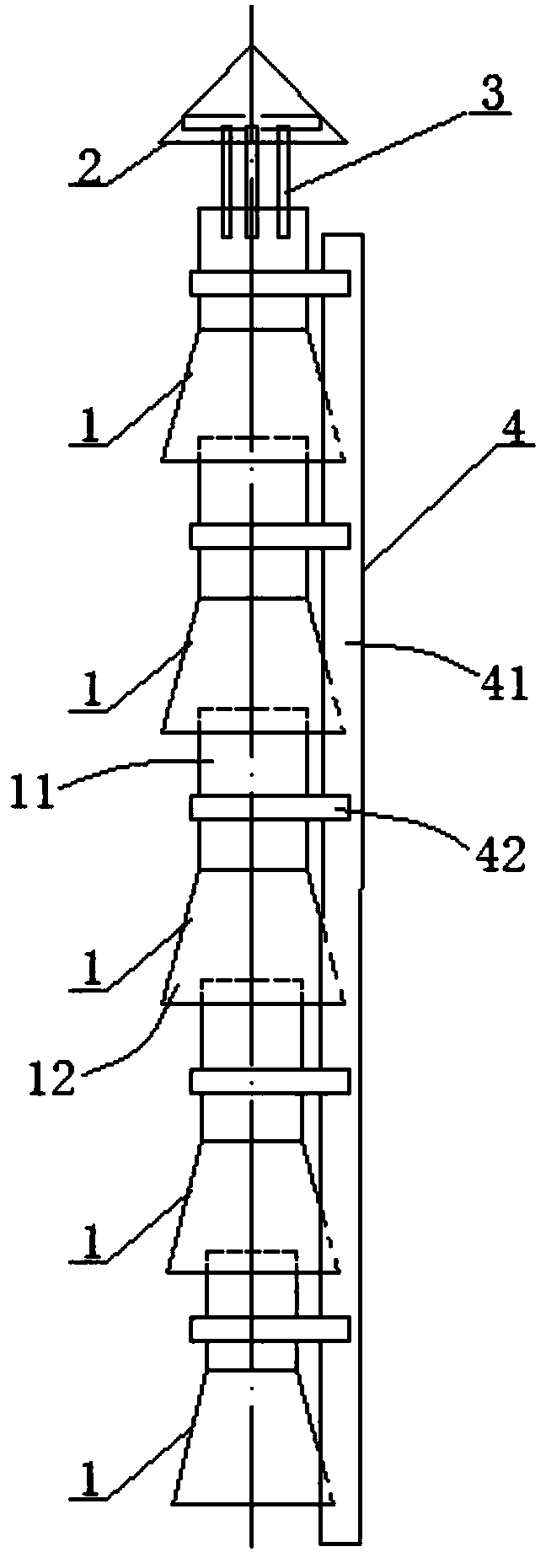

[0014] like figure 1 As shown, the flue gas guide device for the coke oven riser of the present invention is arranged at the gas release port of the riser; it includes a multi-layer guide pipe 1, a conical wind cap 2 and a mounting bracket 4; the guide pipe 1 It consists of an upper straight pipe 11 and a lower tapered pipe 12. The inner diameter of the lower opening of the tapered pipe 12 is larger than the inner diameter of the upper opening; the diversion pipes 1 of each layer are connected sequentially from top to bottom, and the diameter of the straight pipe 11 and the corresponding tapered pipe 12 Decrease in turn; the upper end of the straight pipe 11 of the lower draft pipe 1 extends into the conical pipe 12 of the adjacent upper draft pipe 1; It is fixedly connected with the uppermost draft tube 1.

[0015] The mounting bracket 4 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com