Detachable movable water treatment functional pool

A functional pool and water treatment technology, which is applied in general water supply conservation, sewage wells, waterway systems, etc., can solve the problems of high construction cost, long construction period, waste of resources, etc., and achieve the effects of improving construction efficiency, shortening construction period, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

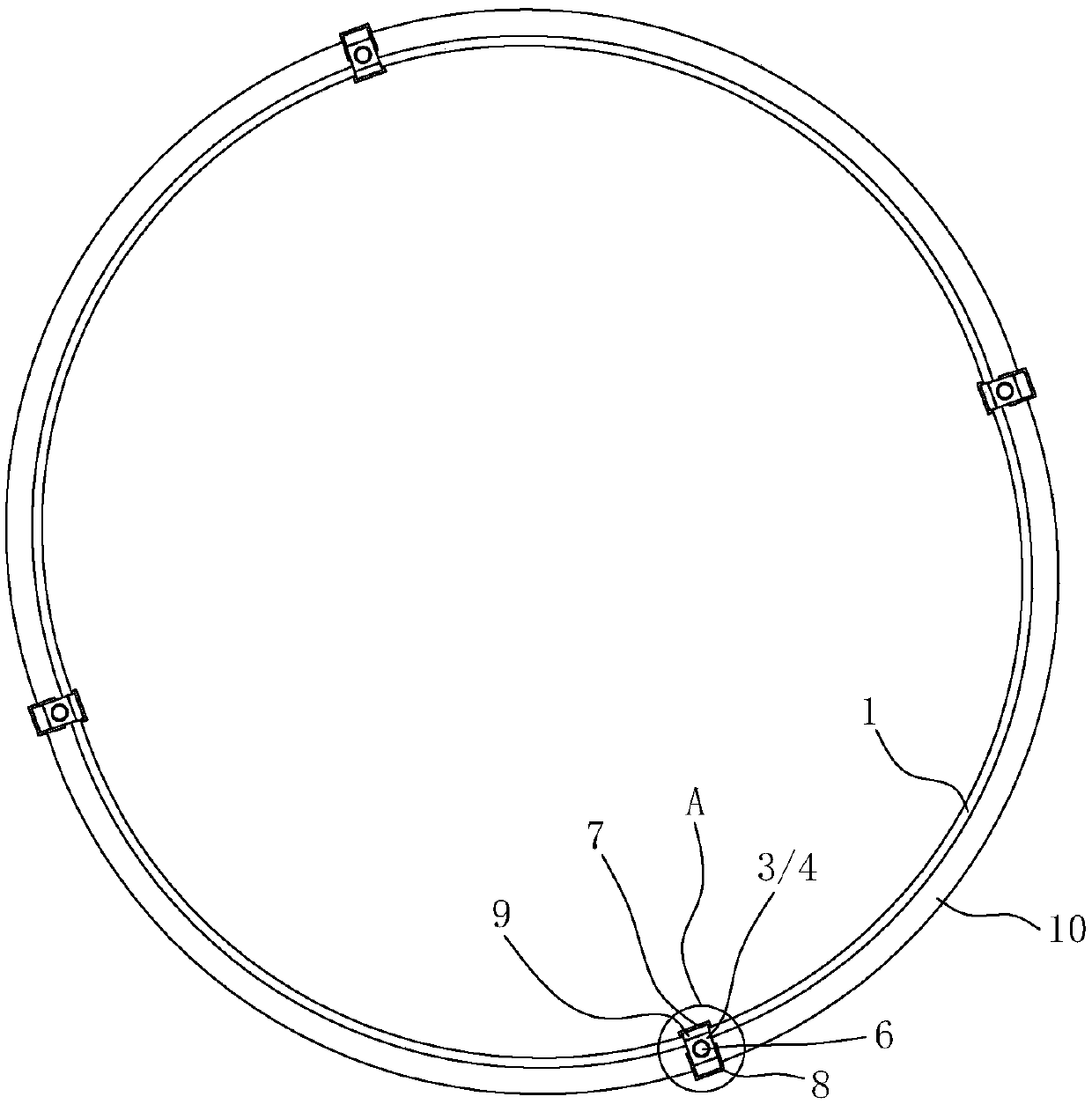

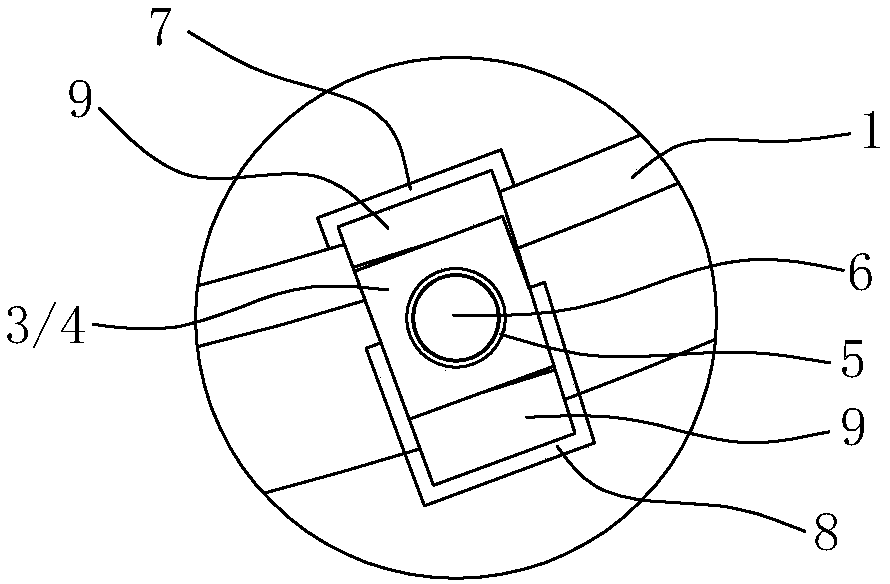

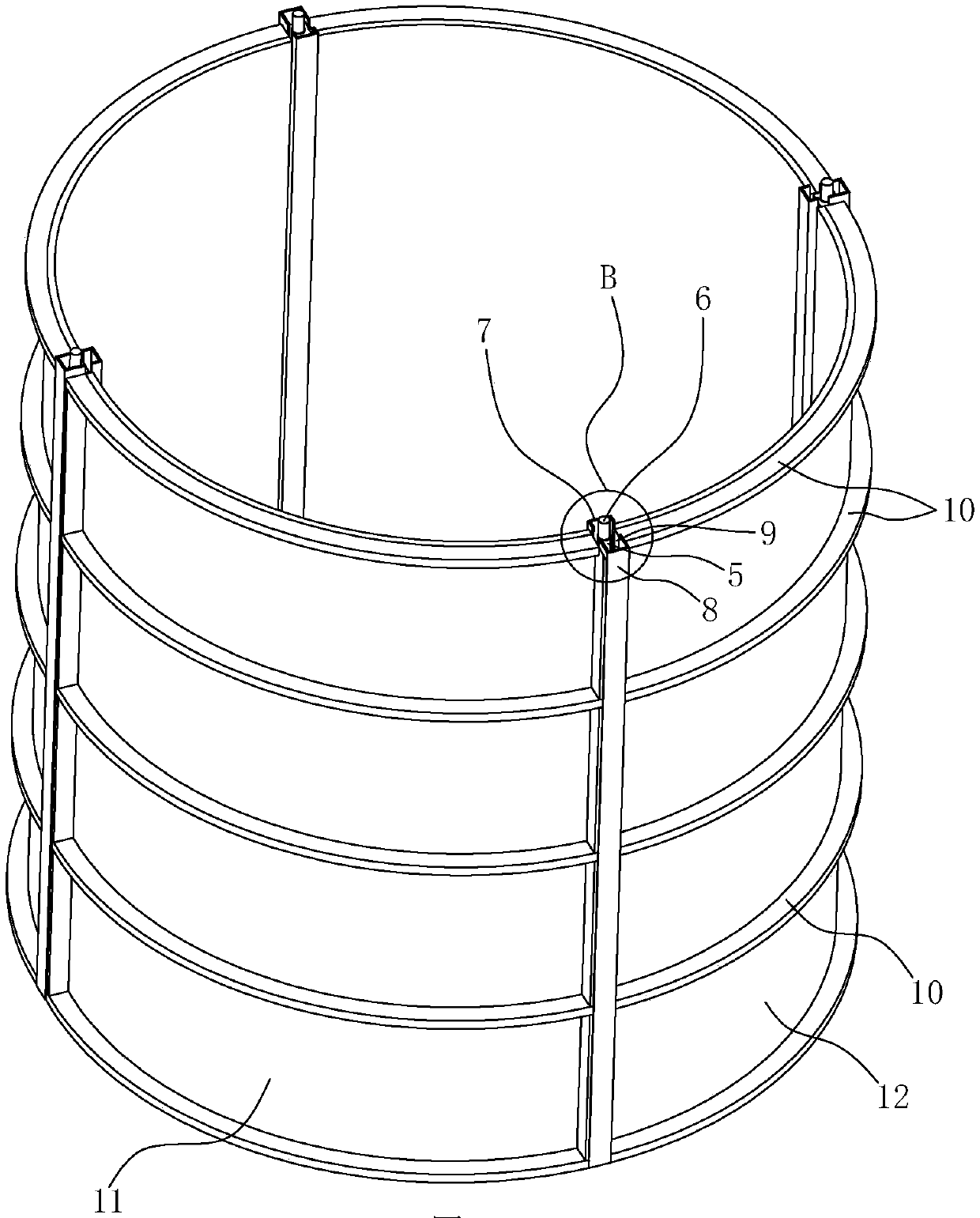

[0020] The technology will be further described below in conjunction with the accompanying drawings.

[0021] The detachable mobile water treatment functional pool of this embodiment includes a plurality of arc-shaped coaming panels 1, and these arc-shaped coaming panels 1 are all made of glass fiber reinforced plastics, and the outer arc-shaped surface of the arc-shaped coaming panels 1 A plurality of reinforcing ribs 10 are formed along the height direction, and arc-shaped hoardings 1 are connected end to end to form a cylindrical functional pool cavity. The connecting edge of two adjacent arc-shaped hoardings 1 is on the upper edge There are many upper inserting ears 2 protruding in the height direction, and there are many lower inserting ears 3 protruding from the side of the second enclosure 12 along the length direction, and one upper inserting ear corresponds to one lower inserting ear, so There are multiple connection points for the upper and lower fitting ears, the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com