A simulation device and method for on-line detection of multi-phase mixed pipeline oil-water interface corrosion

A technology of oil-water interface and simulation device, which is applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., and can solve problems affecting liquid level fluctuations, precise control, difficult liquid level rise and fall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

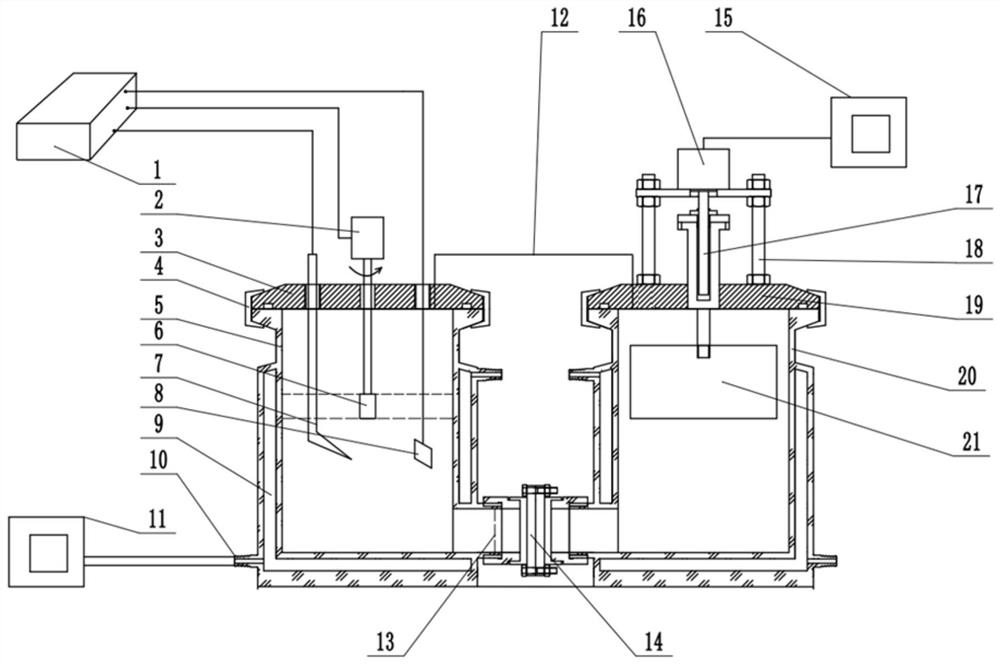

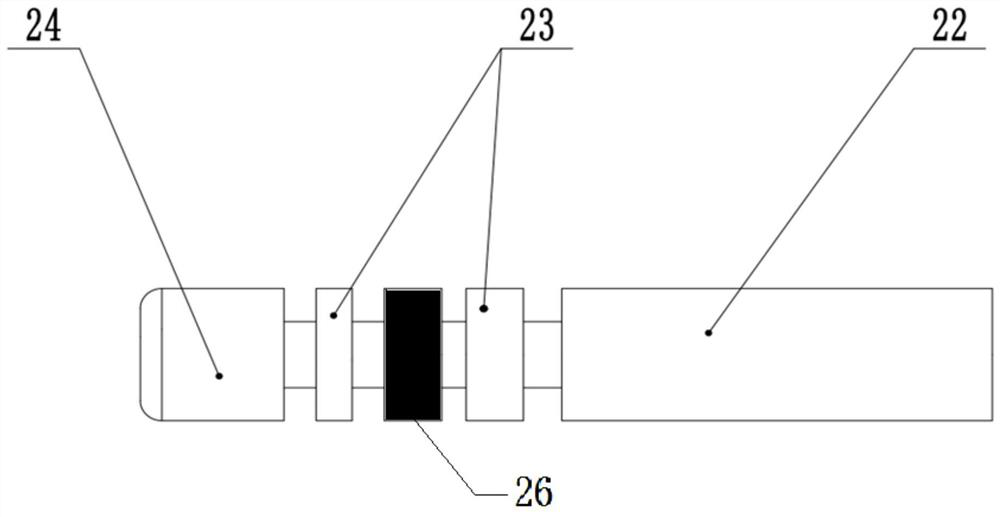

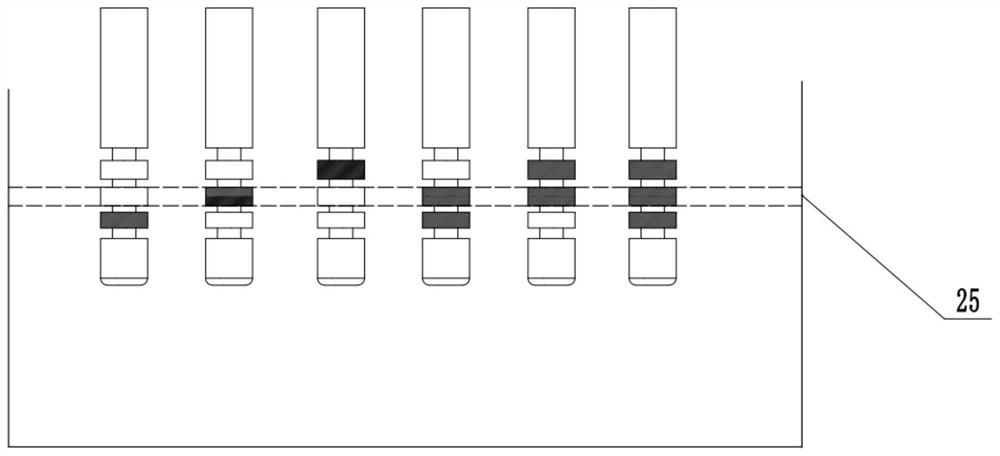

[0029] Such as figure 1 As shown, the present invention provides a simulation device for on-line detection of oil-water interface corrosion in multi-phase mixed pipelines, including an H-type oil-water interface corrosion simulation electrolytic cell, a corrosion test system, a liquid level control system, and a circulating water bath heating system. Among them, the H-type oil-water interface corrosion simulation electrolytic cell is used to simulate the complex corrosion reaction of the oil-water interface; the corrosion test system is used to perform corrosion weight loss test and electrochemical test on the oil-water interface in the H-type oil-water interface corrosion simulation electrolytic cell; The control system is used to adjust the oil-water interface in the H-type oil-water interface corrosion simulation electrolytic cell according to the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com