X-ray detecting compensation block and detecting method for end weld joint of fuel rod

A detection method and fuel rod technology, which are applied in measuring devices, analyzing materials, and using radiation for material analysis, etc., can solve the problems of inability to perform ray detection, penetration thickness, and large scattered ray images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

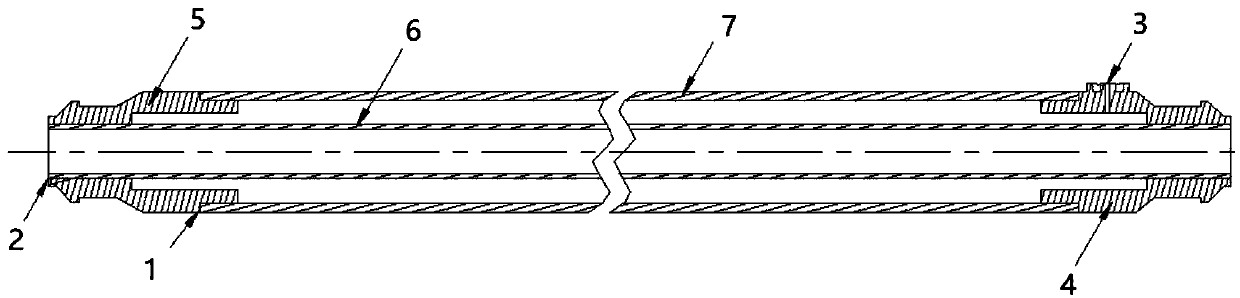

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

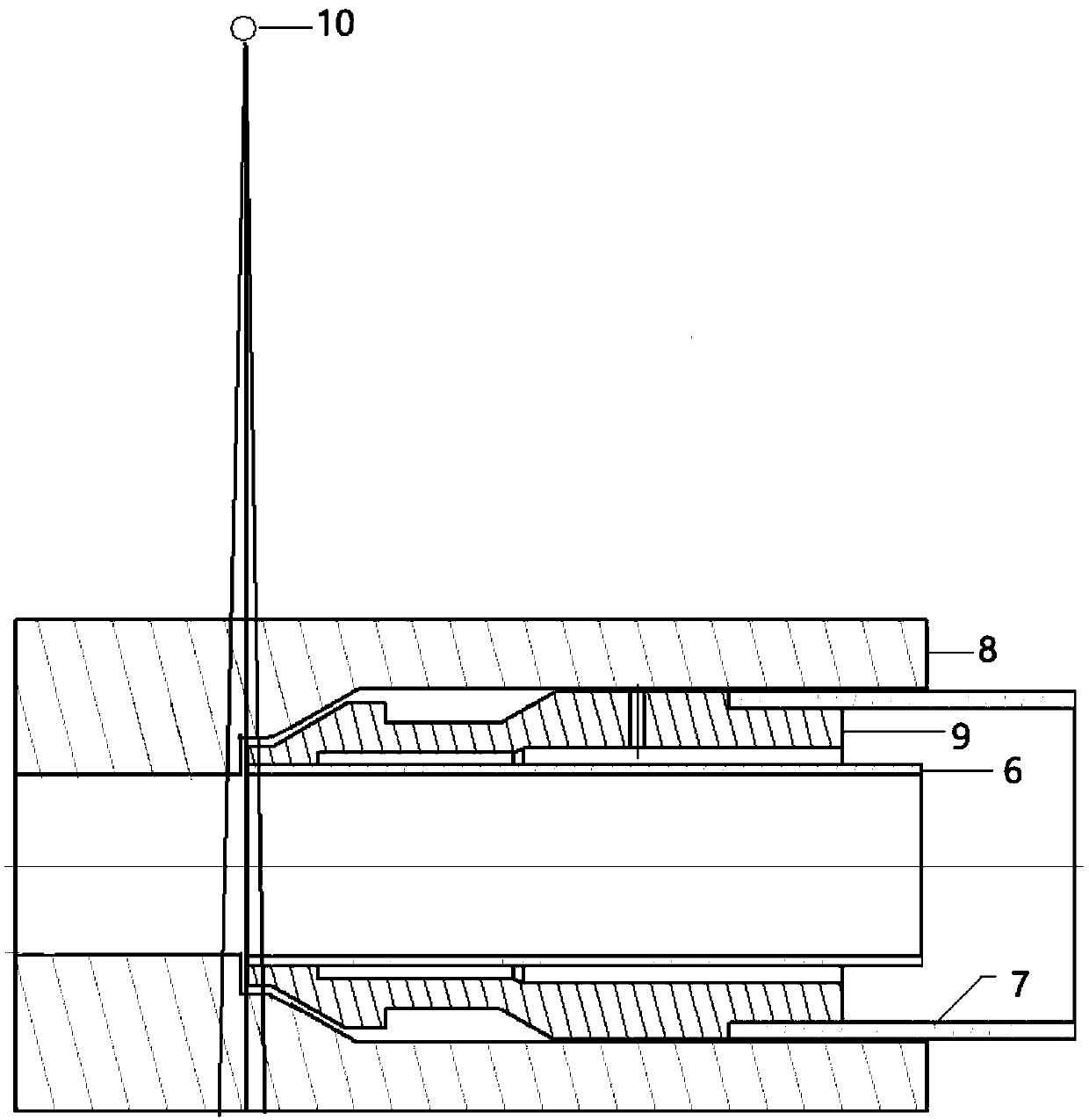

[0036] Such as figure 2 As shown, a fuel rod end weld X-ray detection compensation block is used to detect the girth weld between the fuel rod end plug 9 and the fuel rod inner cladding tube 6 . The compensation block 8 is a cylindrical structure, and a variable-diameter channel is processed inside the compensation block 8 . The reducing channel is coaxial with the compensating block 8 . The diameter of the compensation block 8 is not greater than 25mm.

[0037] The left side opening of the reducing channel is on the left end face of the compensation block 8 , and the right side opening is on the right end face of the compensation block 8 . The reducing channel includes section A, section B and section C from left to right. The section A is an equal-diameter circular hole, the diameter of which is equal to the inner diameter of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com