A method and apparatus for predicting fatigue life of concrete based on Weibull equation and residual deformation

A technology of fatigue life prediction and residual deformation, applied in the direction of instruments, design optimization/simulation, computer-aided design, etc., can solve the problems of complex model form and difficulty in popularization and application, and achieve the reduction of calculation amount, simplification of testing equipment, and simple steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the technical solution provided by the present invention will be further described below in conjunction with the accompanying drawings. This implementation example is an illustration of the present invention, rather than limiting the present invention.

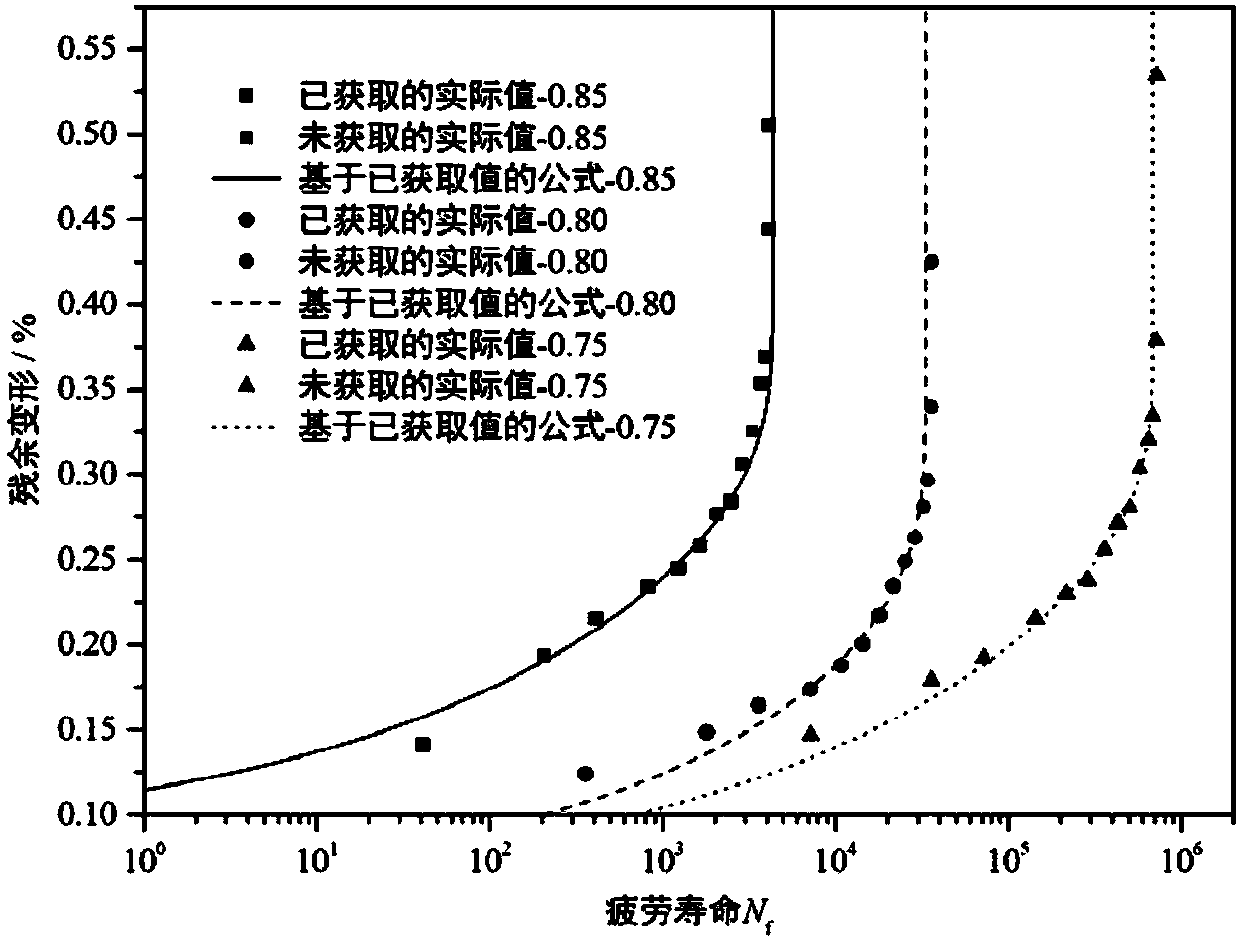

[0022] In this embodiment, the prediction of compression fatigue life and the characterization of fatigue deformation evolution law will be performed on three fiber concrete samples with stress levels of 0.85, 0.80 and 0.75 respectively.

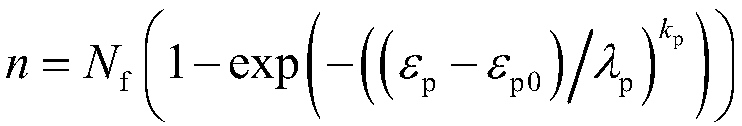

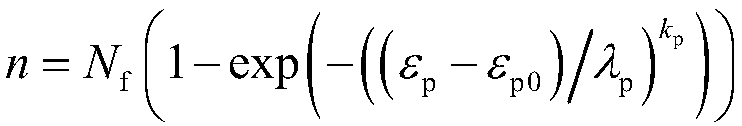

[0023] For the same concrete material, λ p / k p can be set to the same value. Therefore, in this embodiment, a compression fatigue test with a stress level of 0.90 is first performed on three samples of the same fiber concrete to obtain the λ p / k p The average value as described is set to the same value. The compression fatigue test obtained respectively 15 residual deformations ε of the 3 samples p And the number of fatigue load cycles n (as shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com