Unmanned emasculation machine

A detasseling machine and unmanned aerial vehicle technology, which is applied in the field of agricultural engineering, can solve the problems of corn plant damage, poor working environment and high production cost, and achieve the effects of reducing power consumption, improving cutting quality and adjustable cutting angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

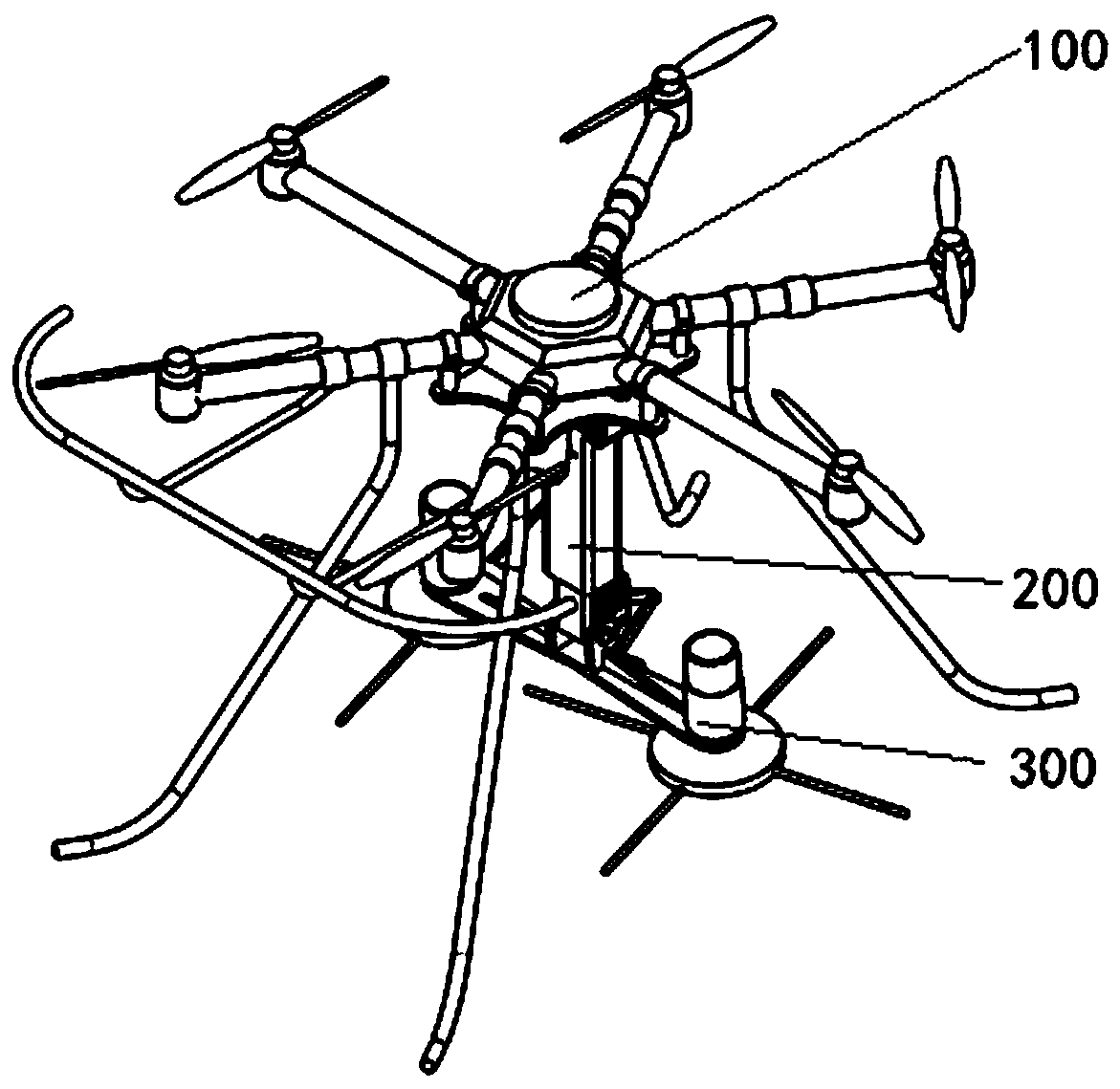

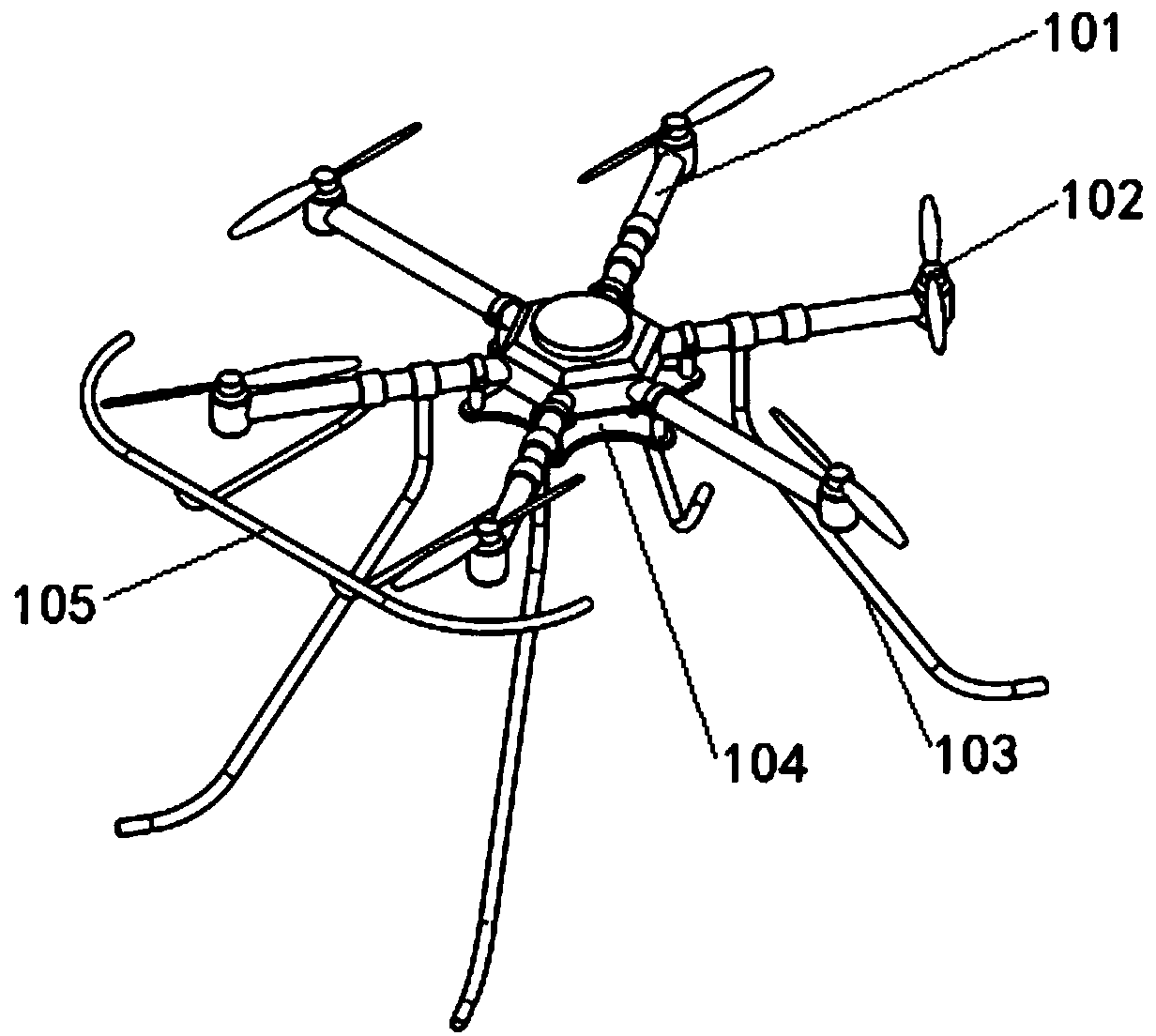

[0057] Such as Figure 1-13 As shown, the present invention provides an unmanned detasseling machine, including: a drone 100 , a telescopic mechanism 200 and a cutting device 300 .

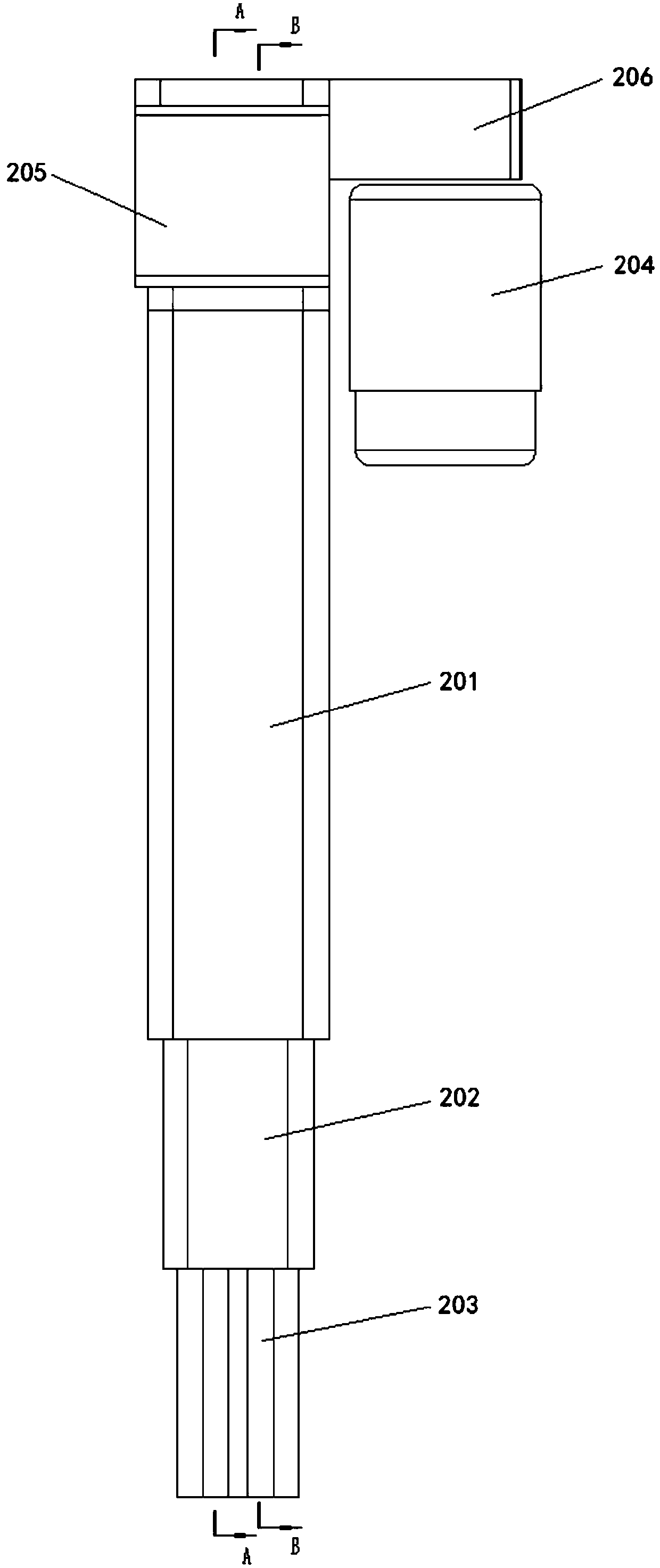

[0058] Such as figure 1 As shown, the unmanned aerial vehicle 100 is arranged on the top of the unmanned detasseling machine, and a mounting frame 104 is detachably connected to the bottom of the unmanned aerial vehicle 100, which is used to fix the telescopic mechanism 200. The height of the telescopic mechanism 200 can be adjusted. The device 300 is hinged to the bottom of the telescopic mechanism 200 , and an angle adjustment steering gear 305 is fixed at the bottom of the telescopic mechanism 200 to adjust the cutting angle of the cutting device 300 .

[0059] Such as figure 2 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com