Method for making duck meatballs

A technology for duck meat and meat balls is applied in the functions of food ingredients, food ingredients as taste modifiers, food ingredients as odor modifiers, etc. Cholesterol content, the effect of making up for the decrease in taste, and enhancing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

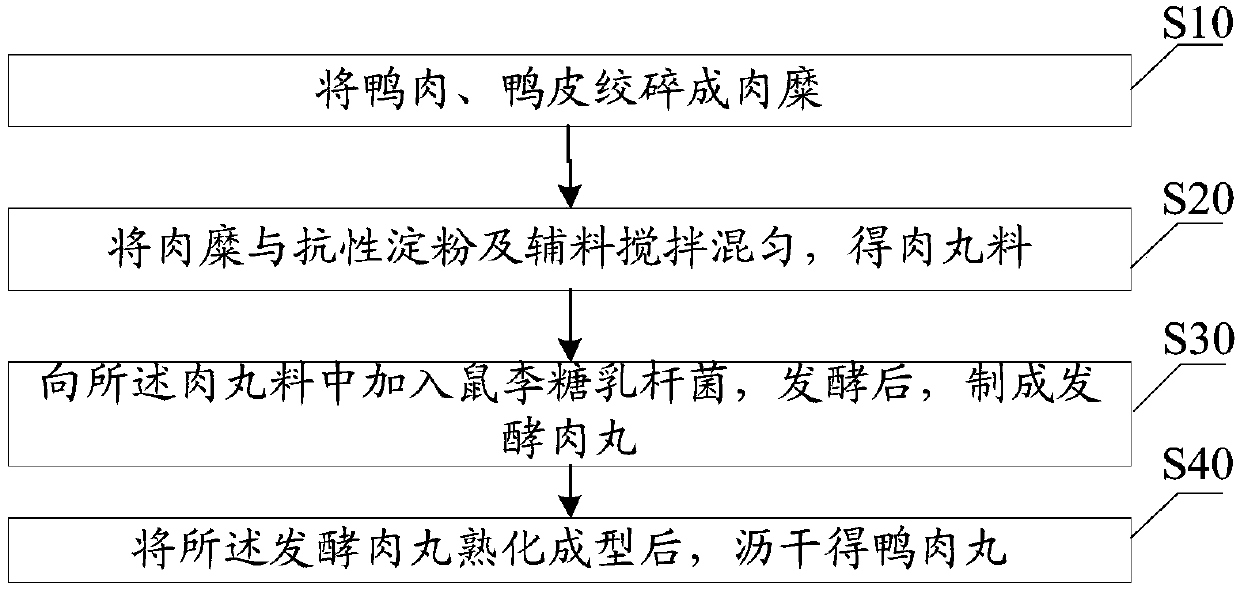

[0023] In view of this, the present invention proposes a method for preparing duck meatballs. The duck meatballs produced by the preparation method have the advantages of rich nutrition, good taste, low fat content, and are healthy and delicious. combine figure 1 A schematic flow diagram of an embodiment of the proposed method for preparing duck meatballs, the method for preparing duck meatballs comprises the following steps:

[0024] Step S10, mincing duck meat and duck skin into minced meat;

[0025] Step S20, stirring and mixing the minced meat, resistant starch and auxiliary materials to obtain the meatball material;

[0026] Step S30, adding Lactobacillus rhamnosus to the meatball material, after fermentation, making fermented meatballs;

[0027] Step S40, after the fermented meatballs are matured and shaped, drained to obtain duck meatballs.

[0028] Wherein, the parts by weight of the duck meat, duck skin, resistant starch and Lactobacillus rhamnosus are respectively...

Embodiment 1

[0037]Mince the garlic and ginger and set aside. Cut 20g of duck meat and 5g of duck skin into small pieces after thawing in running water, deboning and cleaning, and grind them into minced meat with a meat grinder. Mix 3g of soybean protein, 12g of resistant starch and 1g of table salt, then add the mixture to minced meat, stir evenly, then add 10g of egg white, 0.5g of minced ginger, 1g of minced garlic, 0.2g of condiments and water, and stir evenly to obtain Meatball ingredients. Add 0.5 g of Lactobacillus rhamnosus to the meatball material and ferment at 42°C for 2.5 hours to obtain a fermented meat material, and then make a plurality of fermented meat balls with a diameter of about 2 cm from the fermented meat material. Put the fermented meatballs into 90°C water and cook until the fermented meatballs float on the water surface, then continue to boil for 10 minutes, remove and drain to obtain duck meatballs.

Embodiment 2

[0039] Mince the garlic and ginger and set aside. Cut 30g of duck meat and 3g of duck skin into small pieces after thawing in running water, deboning, and cleaning, and grind them into minced meat with a meat grinder. Mix 4g of soybean protein, 13g of resistant starch and 1.2g of table salt, then add the mixture to the minced meat, stir well, then add 12g of egg white, 0.8g of minced ginger, 1.2g of minced garlic, 0.6g of seasoning and water, mix well , Get meatballs. Add 0.7 g of Lactobacillus rhamnosus to the meatball material and ferment at 44°C for 3 hours to obtain a fermented meat material, and then make a plurality of fermented meatballs with a diameter of about 2 cm. Put the fermented meatballs into 95°C water and cook until the fermented meatballs float on the water surface, then continue to boil for 8 minutes, remove and drain to obtain duck meatballs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com