Operation method of automatic ground cleaning equipment

A ground cleaning and operation method technology, applied to cleaning equipment, cleaning devices, cleaning machinery, etc., can solve the problems of secondary pollution, increase the cleaning burden of users, and the inability to clean the ground completely, so as to reduce the operating burden and wipe the floor. better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

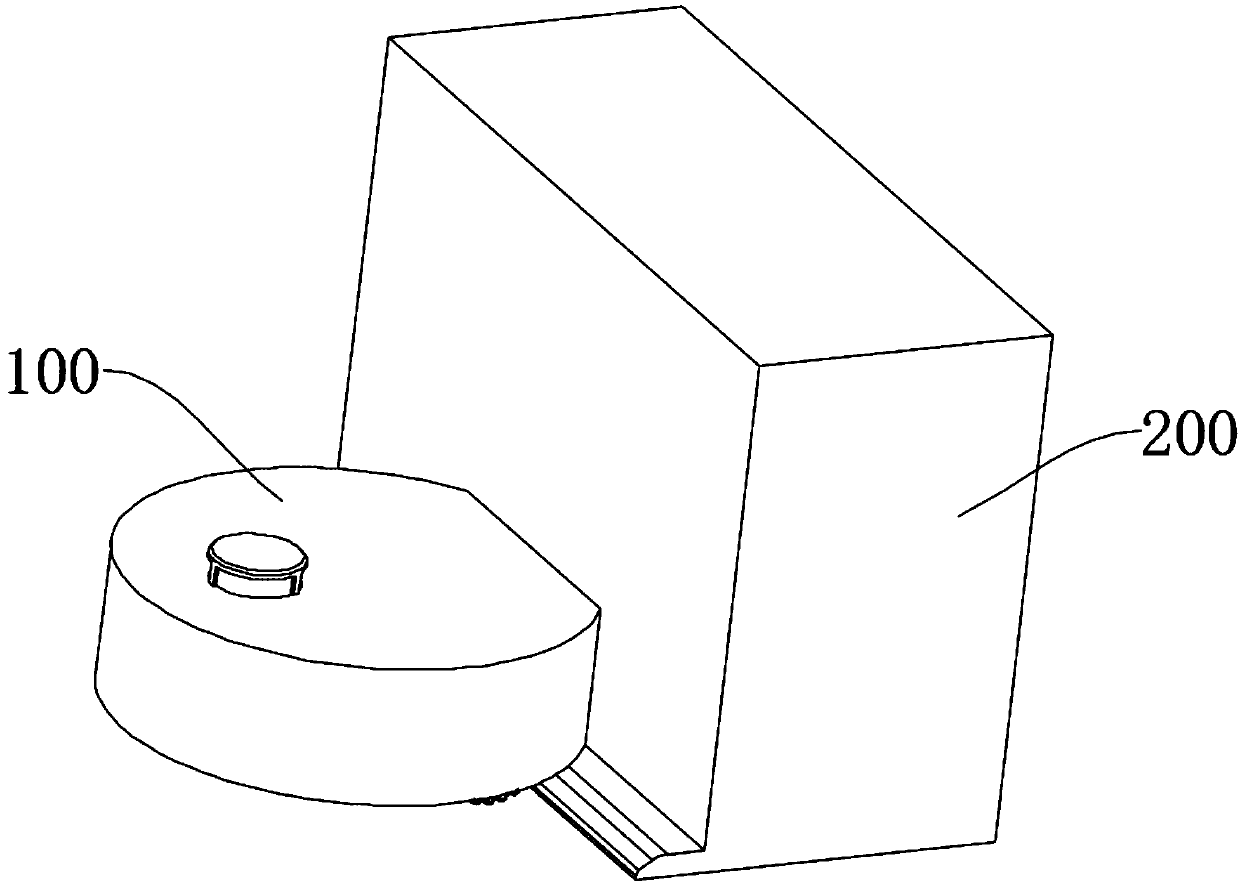

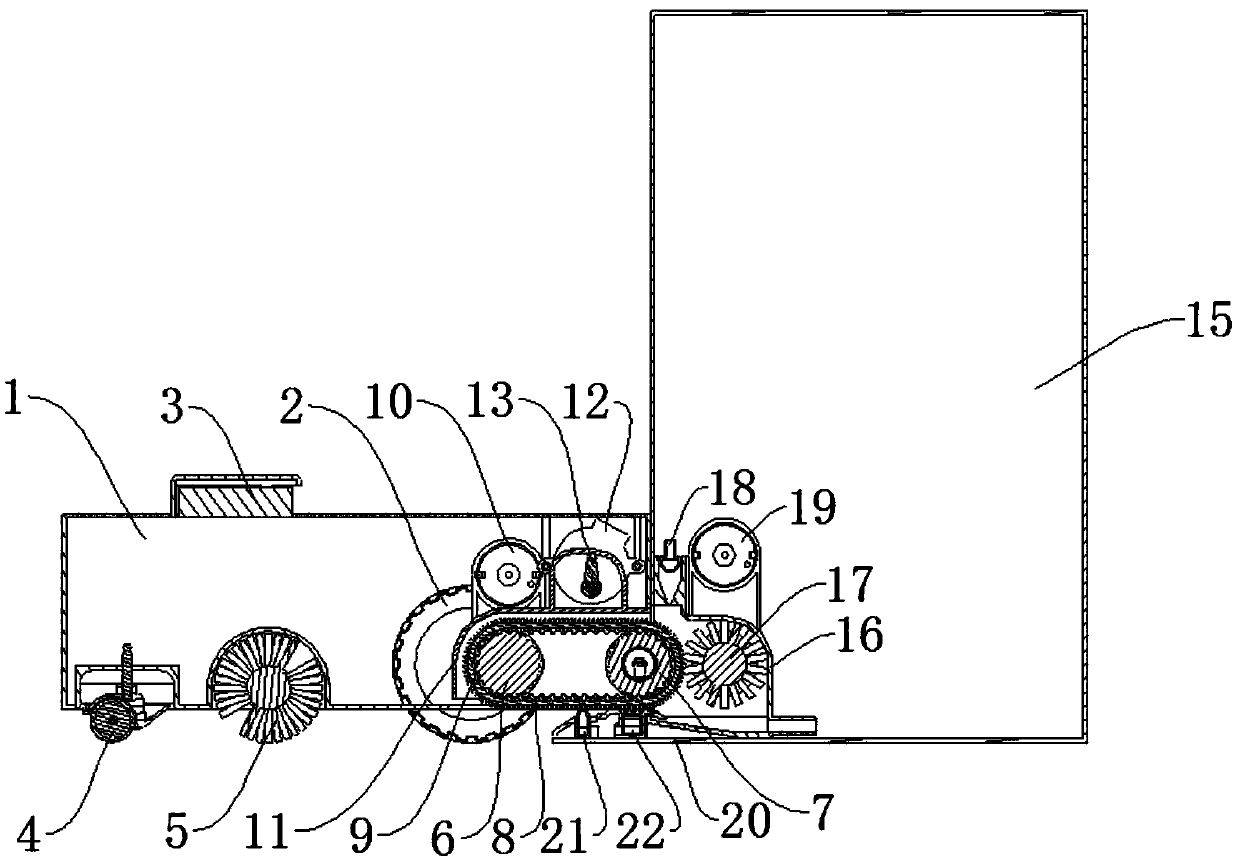

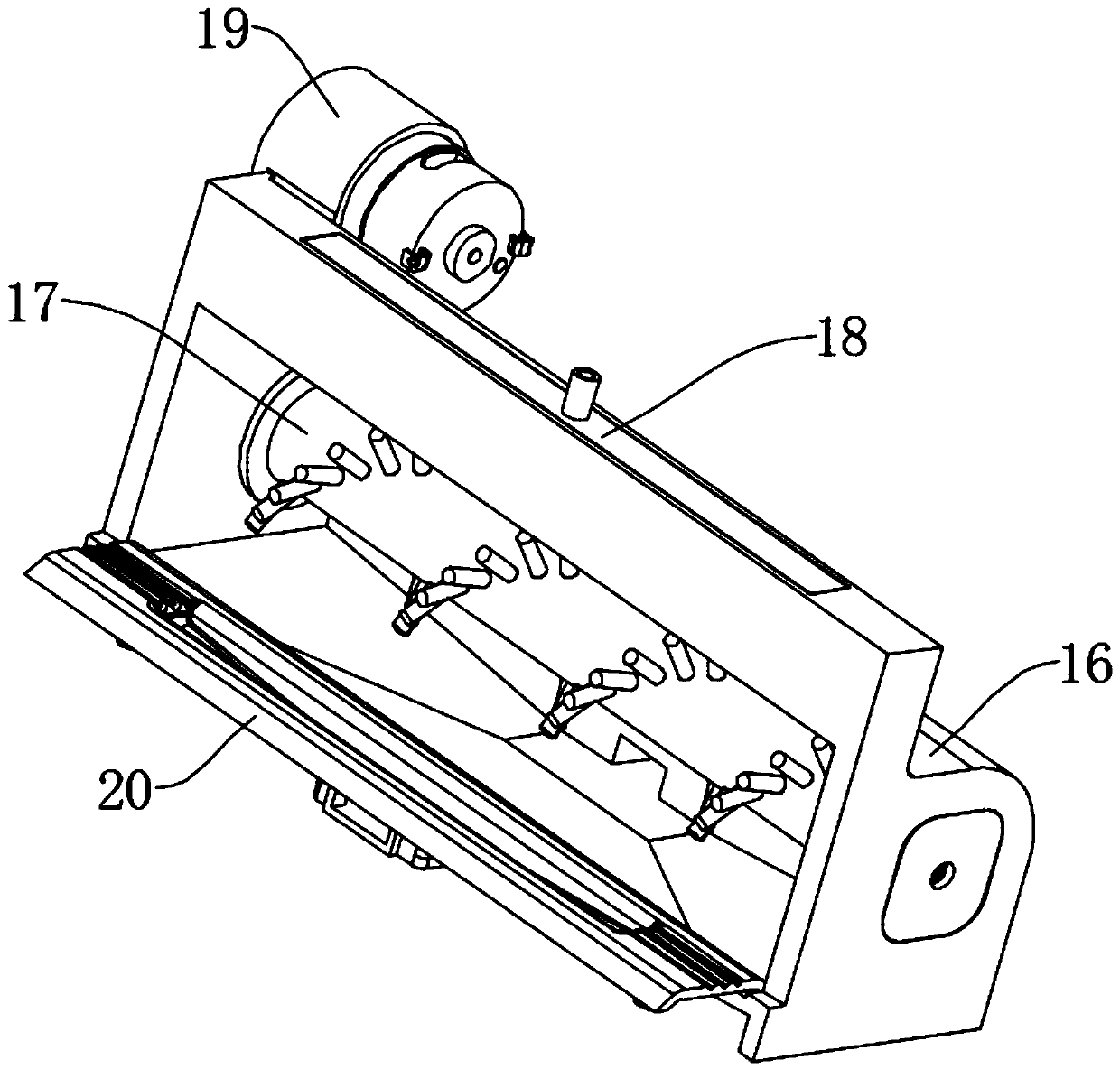

[0036] refer to Figures 1 to 6 As shown in , the automatic floor cleaning equipment provided in this embodiment includes an automatic cleaning robot 100 and a cleaning seat 200, wherein the rear end of the robot body 1 of the automatic cleaning robot 100 is provided with a mopping mechanism 110, and the mopping mechanism 110 includes a mopping mechanism 110 that is rotatably connected to the robot. The rotating assembly on the body 1, the crawler-type wiper 9 that is set outside the rotating assembly and rotates accordingly; the cleaning seat 200 includes:

[0037] The outer box body 15 has an opening for stretching into the crawler-type wiper 9 on the front side;

[0038] Water supply mechanism, its water outlet just stretches into the side behind opening for caterpillar type wiping cloth 9;

[0039] The cleaning brush is installed in the outer casing 15, and is opposed to the side where the crawler-type wiper 9 stretches into the opening, so as to break away from the dirt ...

Embodiment 2

[0048] refer to Figure 7 As shown in , the structure and content of the automatic floor cleaning equipment provided by this embodiment are basically the same as those of the above-mentioned embodiment 1, the only difference is that in this embodiment, the cleaning brush is a flocking board brush, The plate portion 25 in the inner housing 16 and the bristle group 26 arranged on the front side of the plate portion 25 are arranged against the front end of the caterpillar-type wiper 9 extending into the inner housing 16 . In addition, the flocking board brush can also be driven by a driving mechanism to move back and forth or up and down to enhance the decontamination effect.

Embodiment 3

[0050] refer to Figure 8 with Figure 9 As shown in , the structure and content of the automatic floor cleaning equipment provided by this embodiment are basically the same as those of the above-mentioned embodiment 1, the only difference is that in this embodiment, the inside of the driven wheel 7 is a hollow structure and is fixed with the first Six drive motors 27, an eccentric block 37 is set on the output shaft of the sixth drive motor 27, which is used to drive the driven wheel 7 to vibrate as a whole by the eccentric inertia generated when the eccentric block 37 is driven by the sixth drive motor 27 to rotate, thereby scrubbing the floor The effect is better. Further, a brush plate (not shown) is also accommodated inside the driven wheel 7, on which two circular carbon rings as positive and negative poles are printed on the brush plate, and the positive and negative poles on the sixth drive motor 27 rear end The negative terminals are respectively abutted on two circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com