Manufacturing technique of depth scale and rolling mill for manufacturing technique

A technology of production technology and sounding gauge, which is applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of poor dimensional accuracy and mechanical strength, and achieve easy rolling and shunting, high mechanical strength, and high surface accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The production process of the sounding gauge includes,

[0050] S1: material selection, the selection of circular steel as raw material cross-section;

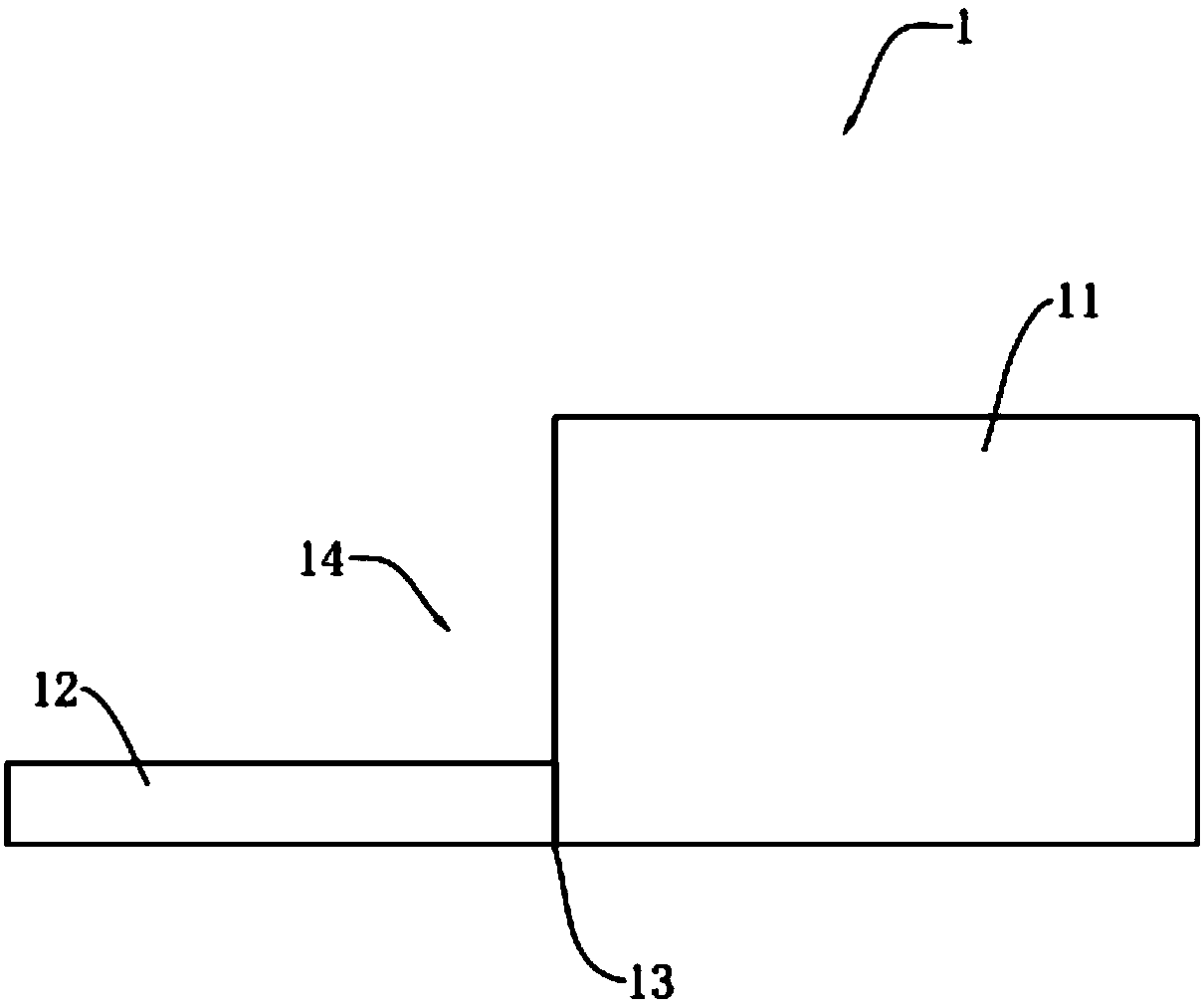

[0051] S2: Calendering deformation, using a number of rolling mills 2 to carry out rolling deformation treatment on round steel. The rolling mill 2 is composed of at least two pressing rollers. A certain gap is left between the two pressing rollers, and rolling grooves are opened on the pressing rollers. The rolling grooves between the pressing rollers form the deformation channel 23 for the raw material to pass through. The raw material passes through several deformation channels 23, and the cross-section of the raw material gradually becomes trapezoidal, and continues to pass through the rolling mill 2 with different deformation channels 23, and the hypotenuse corresponding to the trapezoidal cross-section Gradually roll out the drop gap 14 on the top, so as to obtain the first product with a cross-sectional shape sim...

Embodiment 2

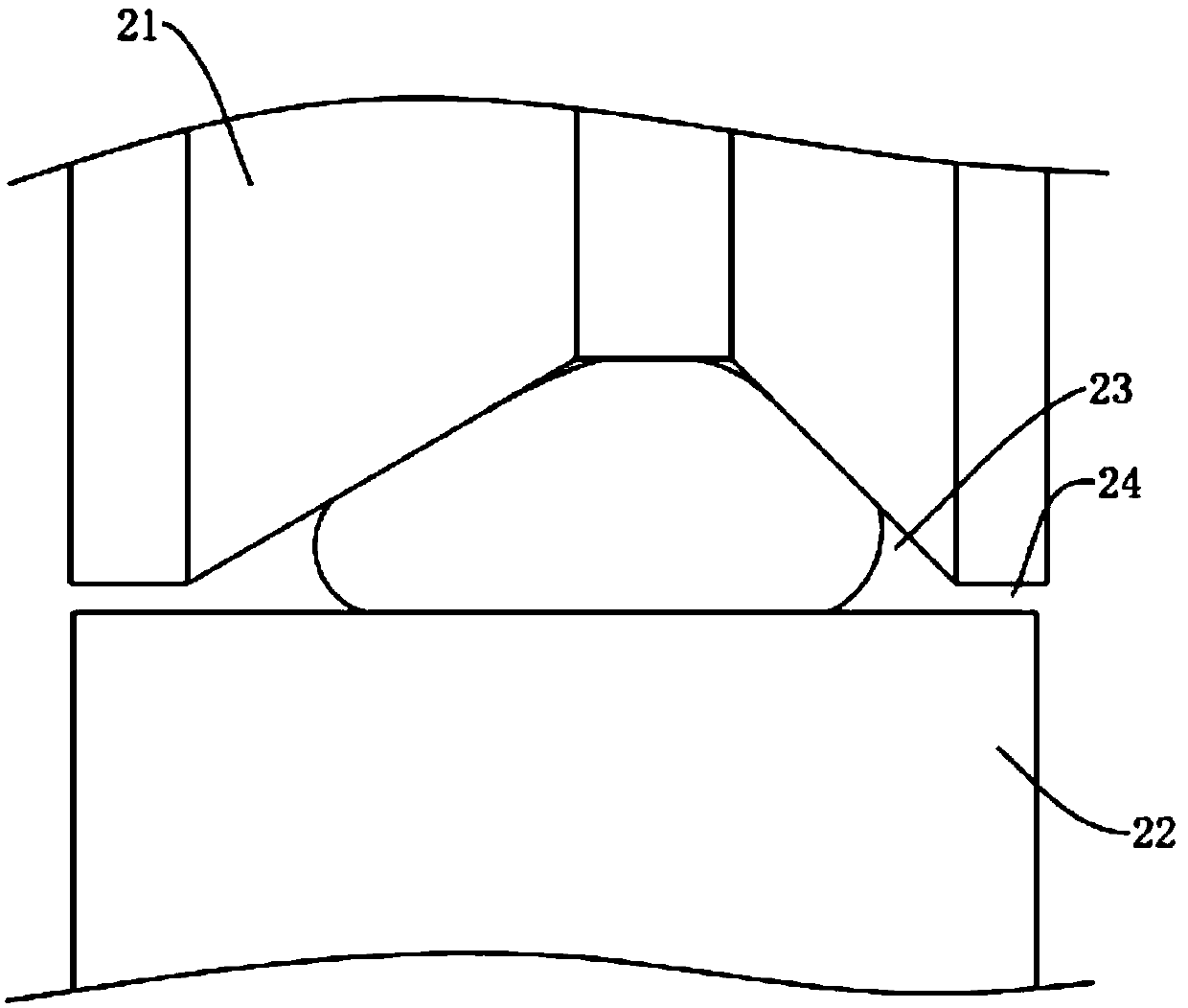

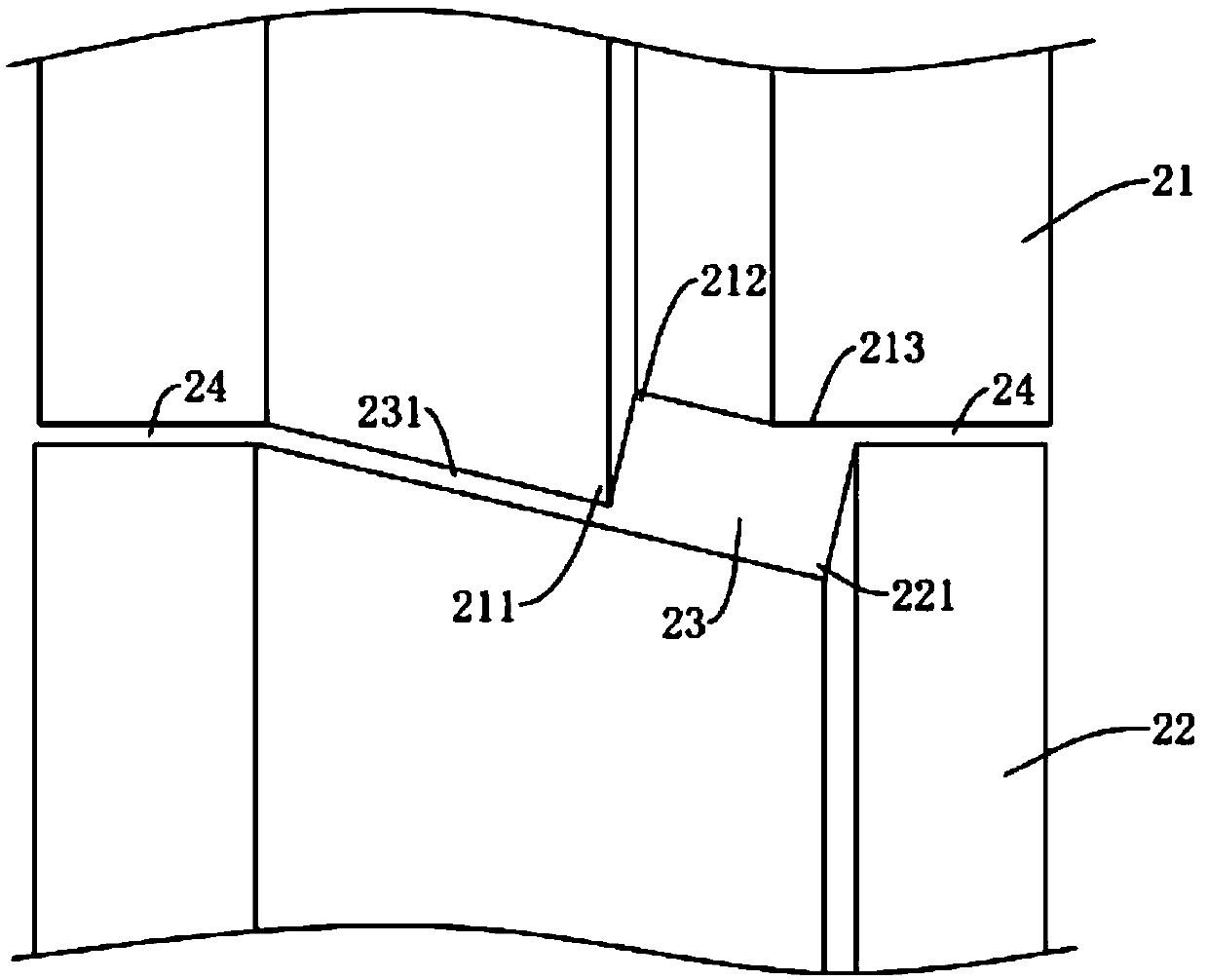

[0064] A rolling mill used for the calendering deformation step in the production of sounding gauges, comprising an upper pressing roll 21 and a lower pressing roll 22, the upper pressing roll 21 and the lower pressing roll 22 are facing each other and there is a gap between the remaining material 112, the upper pressing roll 21 and the lower pressing roll 22 The surface of the lower pressing roller 22 is provided with different processing grooves according to the different processing steps, and the processing grooves form a deformation channel 23 for raw materials to pass between the upper pressing roller 21 and the lower pressing roller 22 .

[0065] Wherein, the upper pressure roller 21 protrudes with a shunt pressure angle 211, and the lower pressure roller 22 is provided with a lower forming angle 221 matching the shunt pressure angle 211. A forming gap 231 and a deformation channel 23 are left between the forming angles 221, the forming gap 231 corresponds to the second b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com