Manufacturing technology for elliptical cam

An elliptical cam and manufacturing process technology, which is applied in the field of harmonic reducers, can solve the problems of elliptical position, dimension, shape and position tolerance, precision loss, and failure to meet design requirements, etc., to improve precision, improve yield, and save processing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail through the following examples. However, it should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the scope of the present invention.

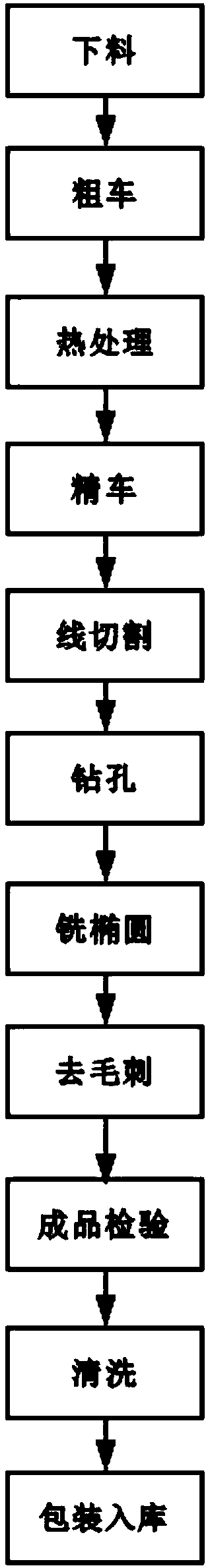

[0027] see figure 1 As shown, the manufacturing process of the elliptical cam according to the present invention has the following process steps: blanking→rough turning→heat treatment→finish turning→wire cutting→drilling→ellipse milling→deburring→finished product inspection→cleaning→packing and warehousing .

[0028] (1) Cutting: Use a band saw to decompose the raw material, and check the raw material blank to ensure that the verticality of the end face is ≦1mm;

[0029] (2) Rough turning: Carry out rough turning on the raw material to be processed by a lathe to form an elliptical cam and it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com