Optical mirror magnetic suspension supporting device

A technology for optical mirrors and support devices, which is applied in the processing and support of large optical mirrors, support devices for optical mirrors, and magnetic levitation support devices for optical mirrors. The effect of service life, simple and reliable operation, and clean working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

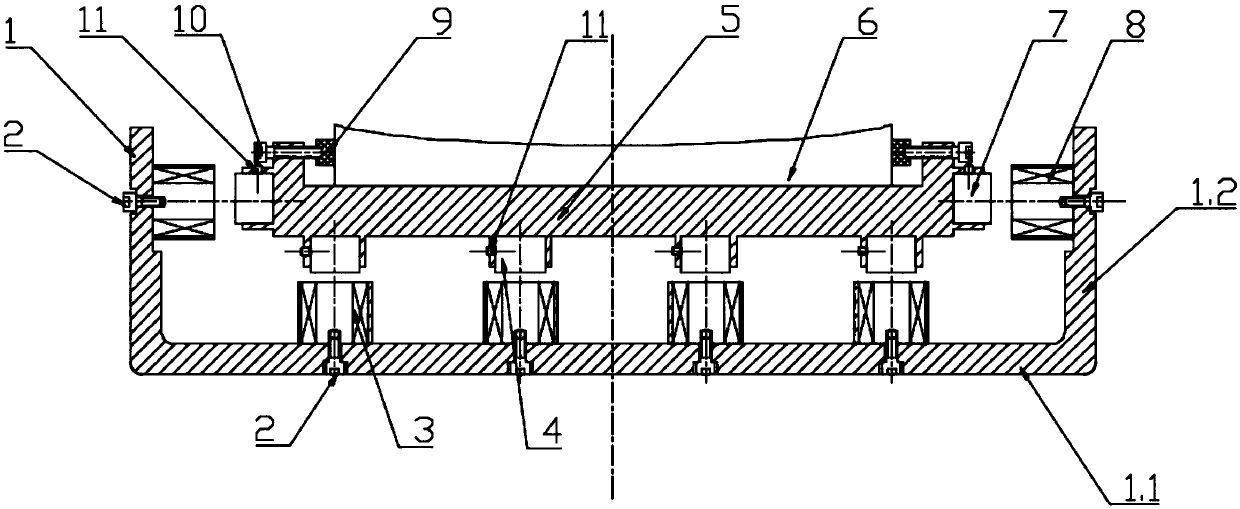

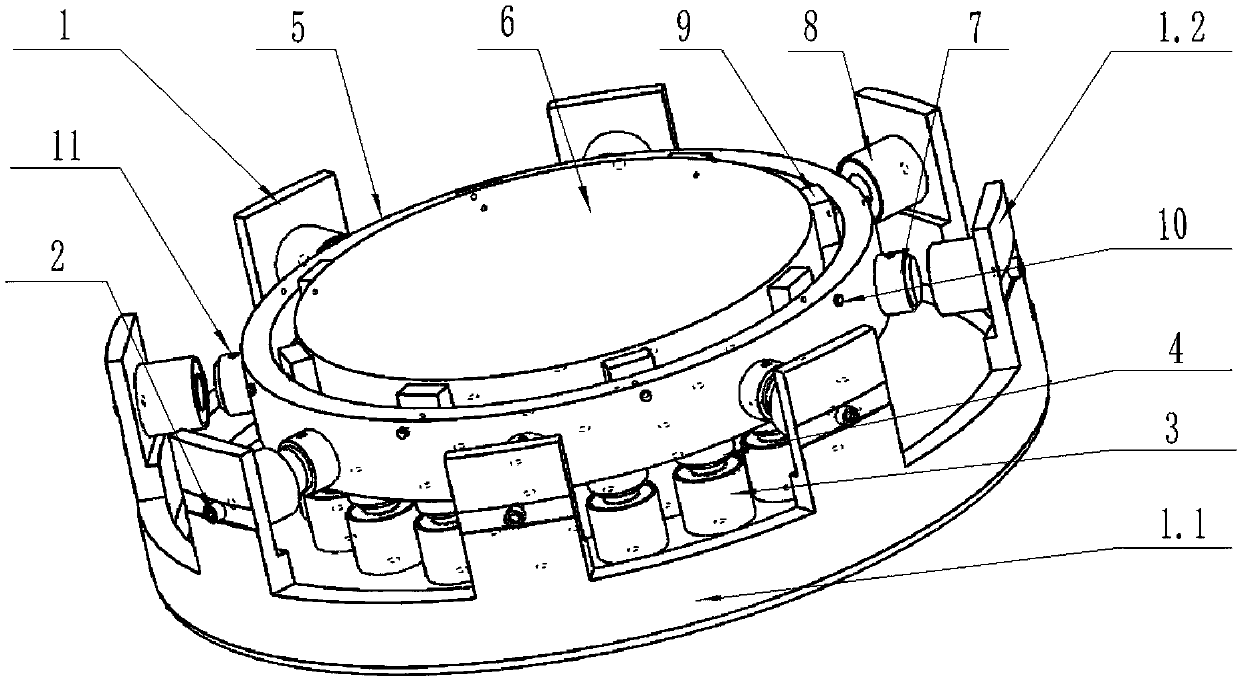

[0018] like figure 1 and figure 2 As shown, an optical mirror magnetic levitation support device includes an axial electromagnetic guide device, a radial electromagnetic guide device and an optical mirror surface fixing device;

[0019] Wherein the axial electromagnetic guiding device comprises an electromagnet mounting frame 1, some electromagnets-3 and some permanent magnets-4, the electromagnet mounting frame 1 comprises a circular base plate 1.1 and a vertical mounting plate 1.2 around the circular base plate edge, the electromagnet -3 is evenly installed on the bottom plate 1.1 of the optical mirror fixing device 5 through screws 2, and the permanent magnet-4 is evenly installed on the bottom of the optical mirror fixing device 5 through set screws 11, and the arranged permanent magnet-4 and electromagnet-1 Uniform one-to-one correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com