High-gloss waterborne coating for perfume glass bottles

A water-based coating and glass bottle technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of increasing the process, affecting the production line capacity, poor alcohol resistance, etc., to increase the solid content of the coating, increase the fullness of the paint film, and excellent durability chemical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

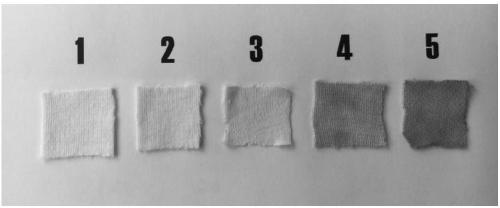

Image

Examples

Embodiment 1

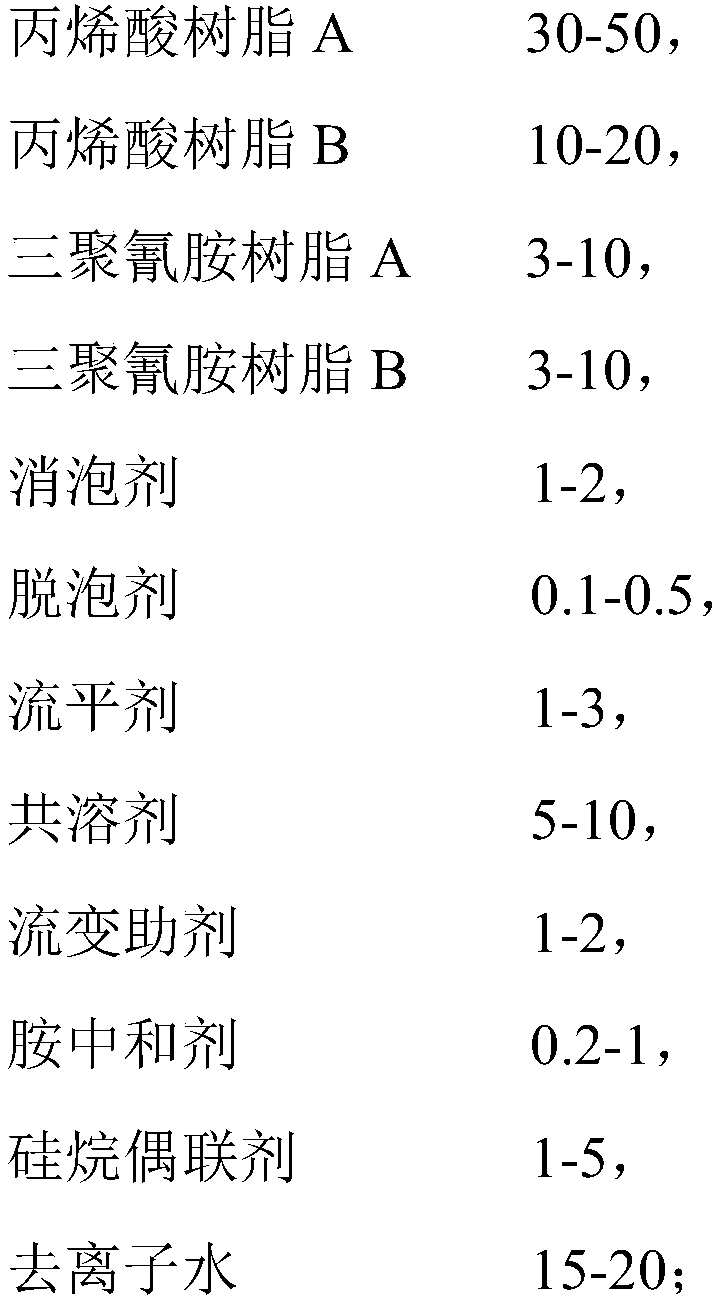

[0049] According to the following preparation method, according to the formula shown in the following table 1, the high-gloss water-based coating for the perfume glass bottle is prepared:

[0050] Component A: Add acrylic resin A to acrylic resin B under slow stirring, stir at a stirring speed of 1000 rpm for 15 minutes, add co-solvent and deionized water, and adjust the pH value to 8. Then add melamine resin A, melamine resin B, defoamer, and leveling agent to the stirring mixture in turn, stir at medium speed (1500 rpm) for 30 minutes, add defoamer, and disperse at high speed (2000 rpm) for 30 minutes , then add an amine neutralizer to adjust the pH value to 8, stir at a medium speed (1500 rpm) for 15 minutes, use a rheological additive to adjust the product viscosity, let it stand overnight, add a silane coupling agent, and use an amine neutralizer again Adjust the pH value to 8, adjust the viscosity with a rheological additive or deionized water, filter with a 400-mesh fil...

Embodiment 2

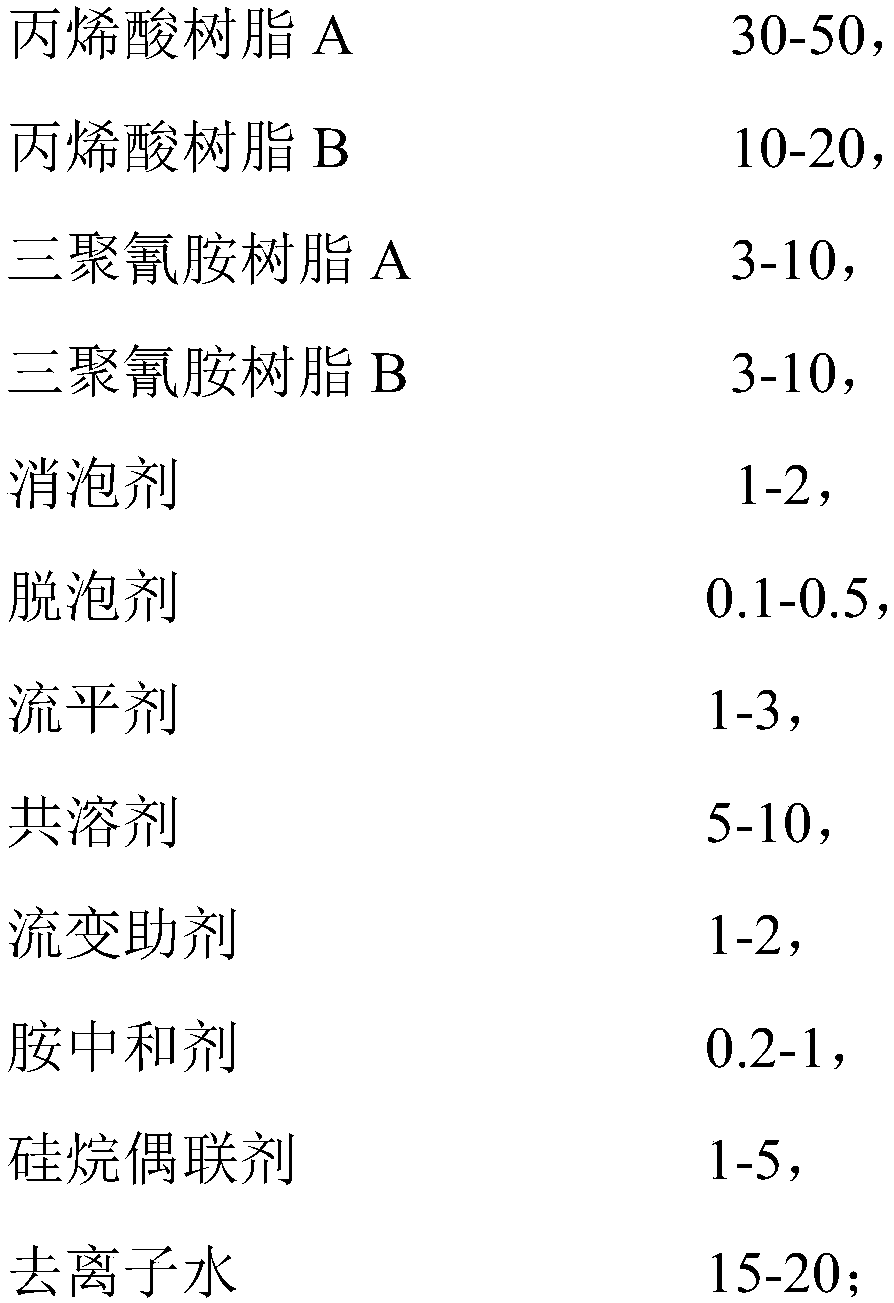

[0060] According to the following preparation method, prepare high-gloss water-based paint for perfume glass bottle according to the formula shown in Table 2 below:

[0061] Component A: Add acrylic resin A to acrylic resin B under slow stirring. After stirring for 20 minutes, add co-solvent and deionized water. After stirring evenly, adjust the pH value to 8.5 with amine neutralizer, and then add to the stirring mixture in turn. Melamine resin A, melamine resin B, defoamer, leveling agent, stir at medium speed (1500 rpm) for 30 minutes, add defoaming agent, disperse at high speed (2000 rpm) for 30 minutes, then add amine neutralizer to adjust pH When the value reaches 8.5, stir at medium speed (1500 r / min) for 15 minutes, adjust the viscosity of the product with a rheological additive, let it stand overnight, add a silane coupling agent, adjust the pH value to 8.5 with an amine neutralizer again, and use a rheological agent. Additives or deionized water to adjust the viscosit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com