Electronic control interlocking circuit system for mote removing machine

A technology of interlocking circuit and dust machine, which is applied in deburring devices, textiles and papermaking, fiber processing, etc. It can solve problems such as signal interruption, carding machine shutdown, and uneven weight of carding sliver, so as to achieve stable weight and avoid The effect of the parking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

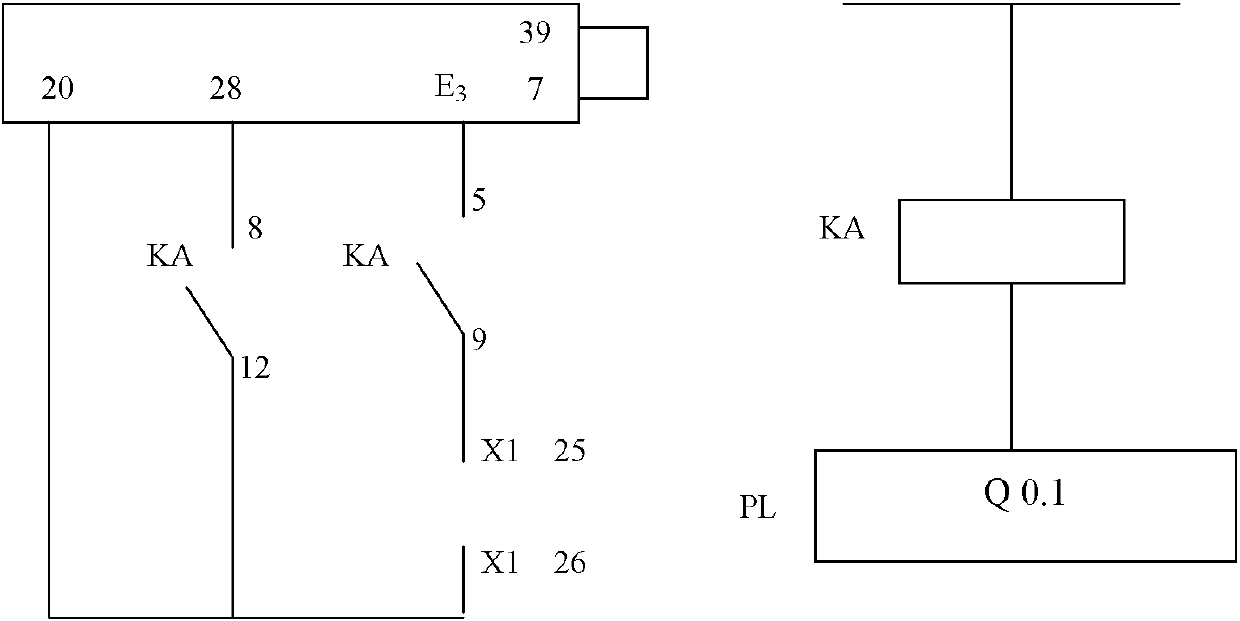

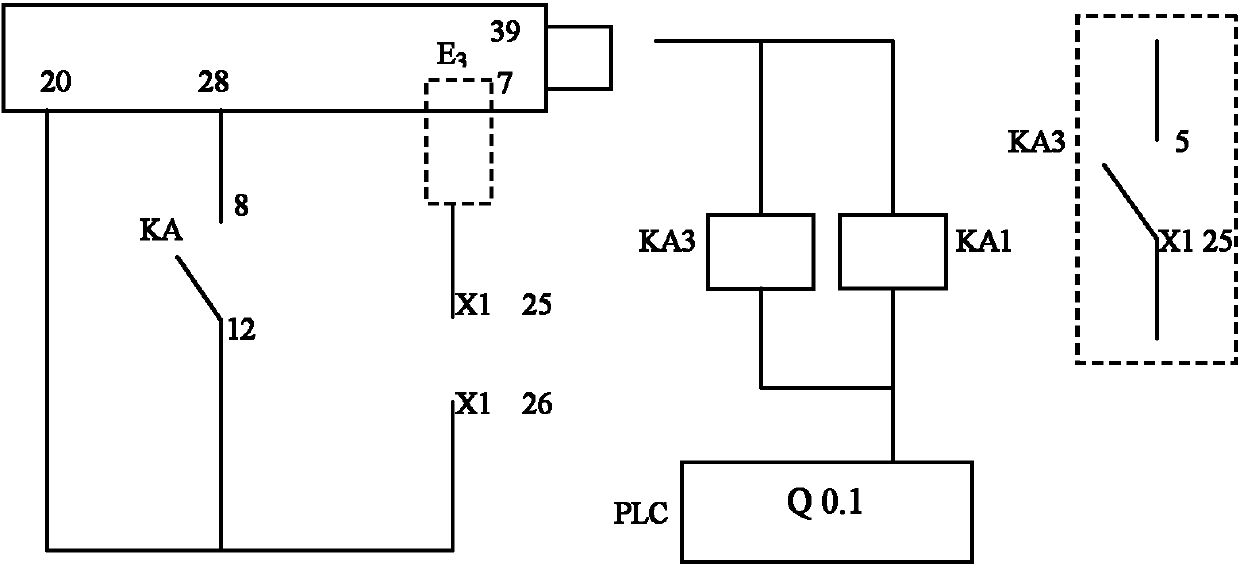

[0013] During the actual use of the FA156 dust remover, the signal interruption often occurs when the FA156 dust remover supplies cotton to the FA203A carding machine. Such as figure 1 as shown, figure 1 It is a schematic diagram of the electric control interlocking circuit for the dust removal machine before improvement, in which KA1 represents a general relay, the circuit where the contacts 28, 8 and 12 are located represents the first control circuit, and the contacts E3, 5, 9, 25 and 26 The line where it is located represents the second control circuit, and PLC represents a programmable logic controller. Through ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com