Low-bath-ratio bobbin dyeing method of ultrafine terylene fibers

A technology of polyester superfine fiber and dyeing method, which is applied in the textile field, can solve the problems of insufficient penetration of dye liquor, difference between the inner and outer layers of colored flowers, and limited load capacity of yarn bobbin, and achieve the effect of increasing dyeing output and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

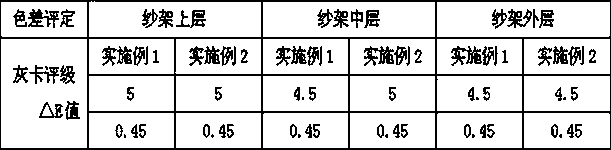

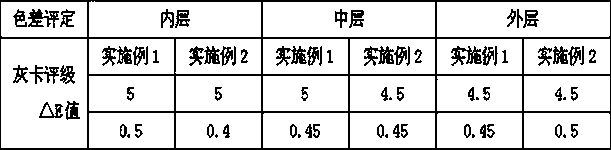

Embodiment 1

[0027] A kind of cheese dyeing method of polyester microfiber with low bath ratio, the dyeing process comprises the following steps,

[0028] High-temperature pre-shrinking process: put the polyester superfine fiber bobbin of DTY 288F 150D into the high-temperature pre-shrinking processor, start from room temperature, raise the temperature to 85°C at a rate of 3°C / min, and continue to heat up at a rate of 1°C / min. Speed up to 110°C, continue to heat up to 125-130°C at a rate of 1.8°C / min, wet for 3.5 hours, and cool down to room temperature naturally;

[0029] Pre-treatment process: wind the polyester superfine fiber after high-temperature preshrinking treatment from the bobbin, and increase the weight of the polyester fiber carried by each bobbin from 0.8-1.0kg to 1.3kg, and determine the constant bath ratio of 1:3, using The cheese is dyed in the dyeing machine, and at the same time, additives such as hydrogen peroxide, alkali-removing agent, penetrant, and stabilizer are ...

Embodiment 2

[0035] A kind of cheese dyeing method of polyester microfiber with low bath ratio, the dyeing process comprises the following steps,

[0036] High-temperature pre-shrinking process: put the polyester superfine fiber bobbin of DTY 288F 150D into the high-temperature pre-shrinking processor, start from room temperature, heat up to 90°C at a rate of 3.2°C / min, and continue to heat up at a rate of 1.2°C / min. Speed up to 115°C, continue to heat up to 130°C at a rate of 2.0°C / min, apply humidity for 3.5 hours, and cool down to room temperature naturally;

[0037] Pre-treatment process: wind the polyester superfine fiber after high-temperature preshrinking treatment from the bobbin, and increase the weight of the polyester fiber carried by each bobbin from 0.8-1.0kg to 1.3kg, and determine the constant bath ratio of 1:3, using The cheese is dyed in the dyeing machine, and at the same time, additives such as hydrogen peroxide, alkali-removing agent, penetrant, and stabilizer are add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com