Automatic grabbing and installing device for large plates

An installation device and storage board technology, which is applied in the direction of lifting equipment safety device, lifting device, construction, etc., can solve the problems such as the automatic installation research of large-scale storage board has not been carried out, the quality of installation is difficult to be guaranteed, and the construction safety is poor. The effect of high ratio to self-weight, high work efficiency and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

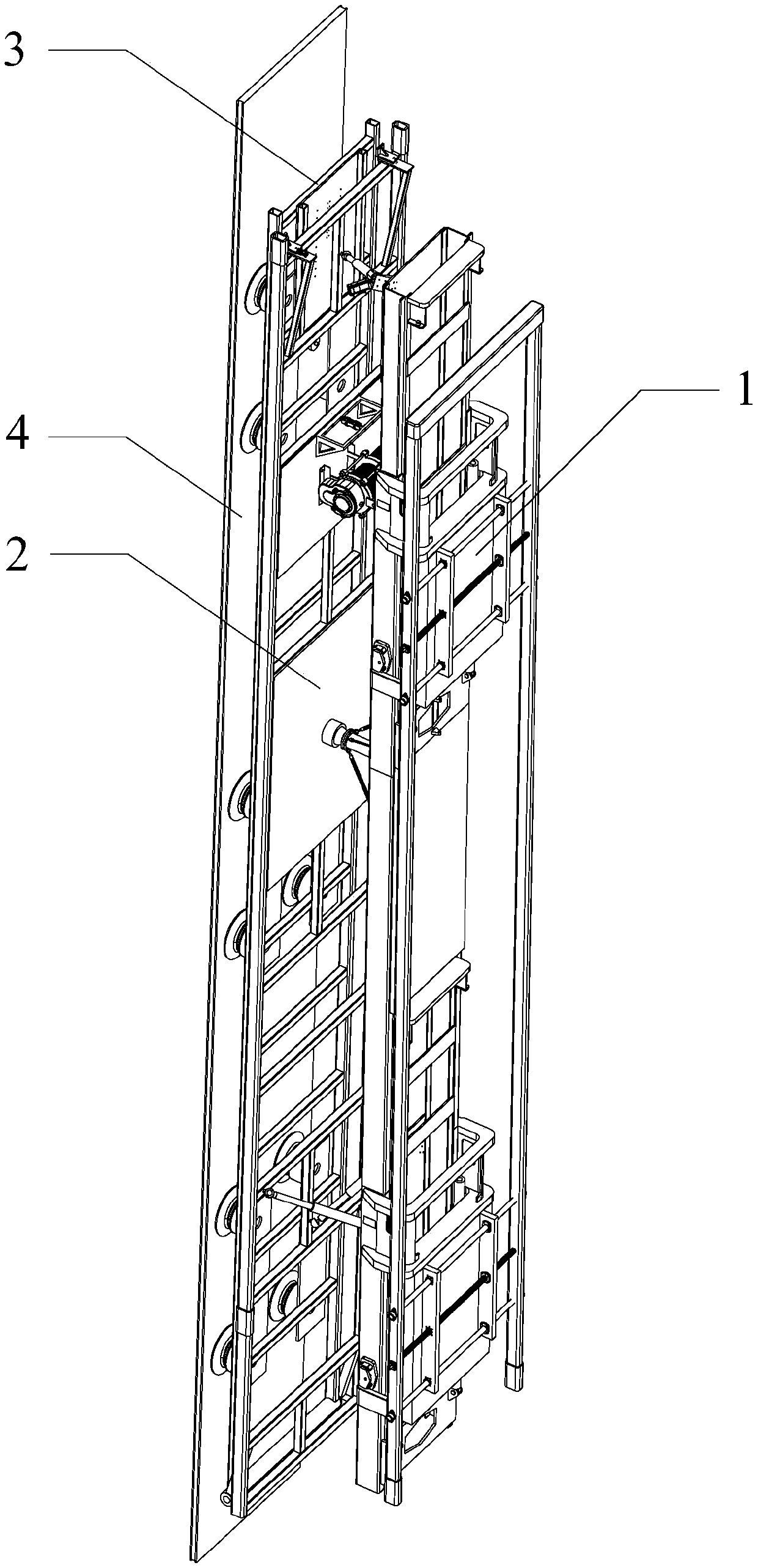

[0032] The invention provides a large-scale library plate automatic grab installation device (referred to as the device, see Figure 1-11 ), which is characterized in that the device includes a translation mechanism 1, a rotation mechanism 2 and an installation end 3; the rotation mechanism 2 is respectively connected to the translation mechanism 1 and the installation end 3 in sequence;

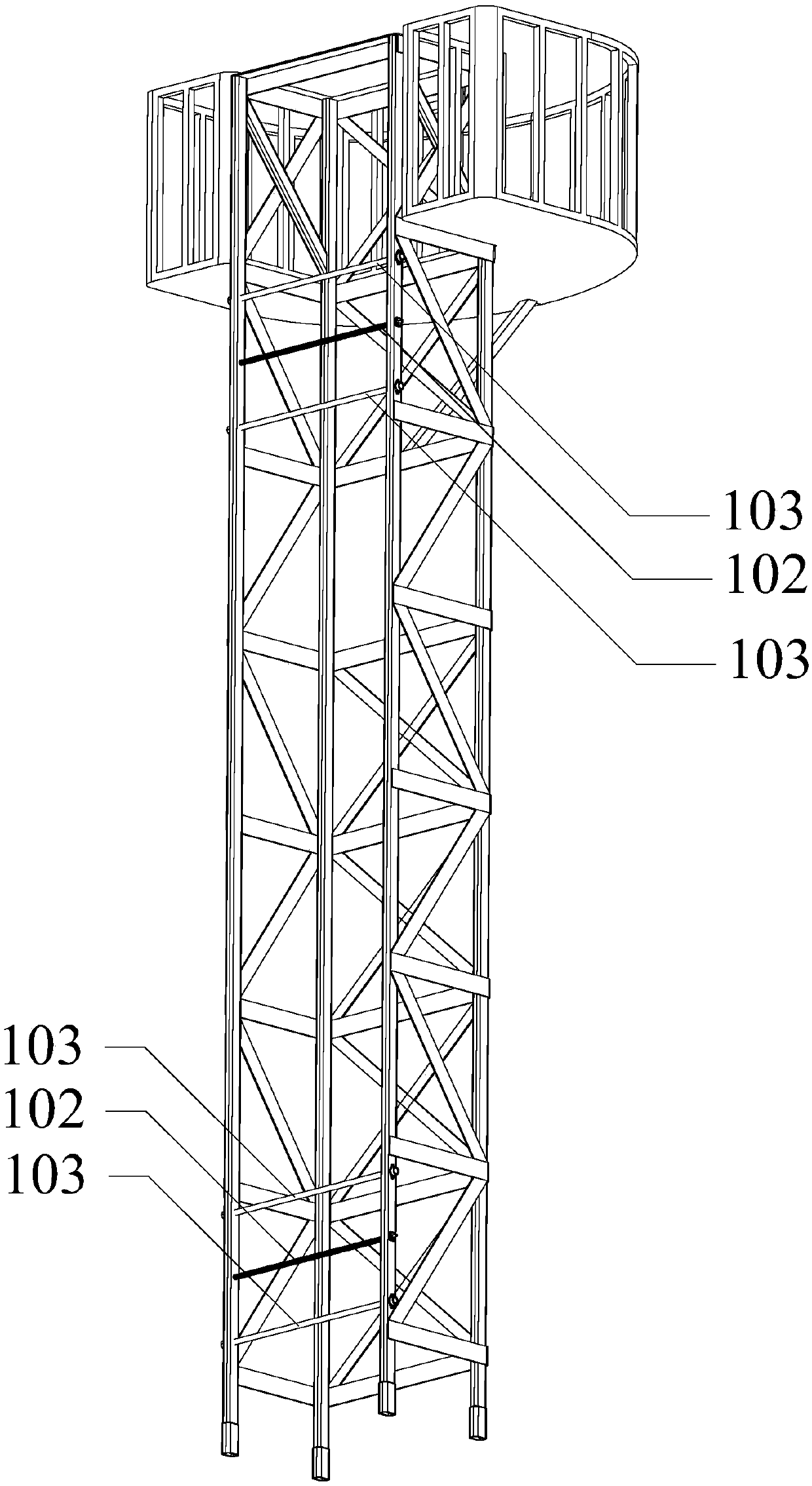

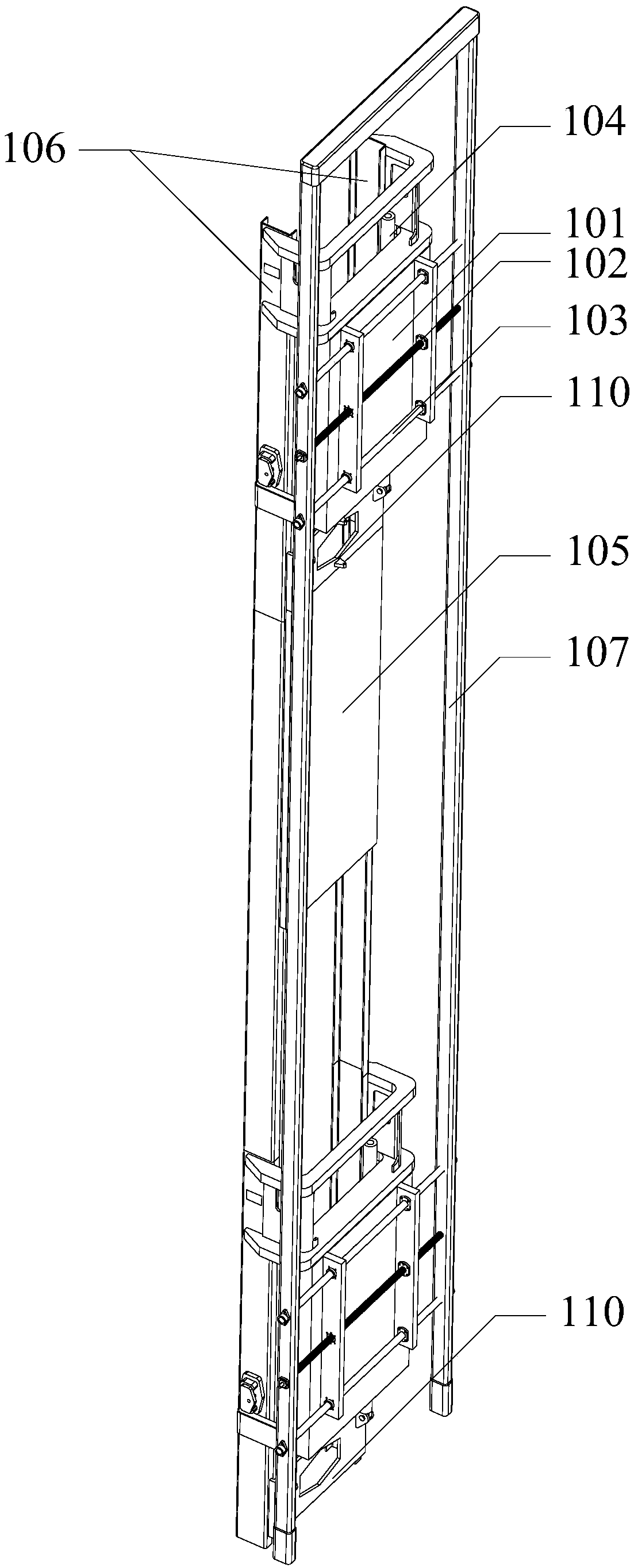

[0033]The translation mechanism 1 includes a translation module 101, a lead screw 102, a linear guide rod 103, a hydraulic cylinder 104, a frame body 105, a mounting tower 107, a lifting frame body 108, a raised plate 109 and a hydraulic cylinder connecting plate 110;

[0034] The installation tower 107 is a rectangular columnar frame body, and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com