Axial flow fan blade, ventilating device and air conditioner

An axial flow fan blade and blade technology, which is applied in the field of impeller machinery, can solve the problems of the air volume of the axial flow fan blade falling, rising, and reducing the working capacity of the blades 4, and achieves the effect of improving the working capacity and reducing the noise of the fan blade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

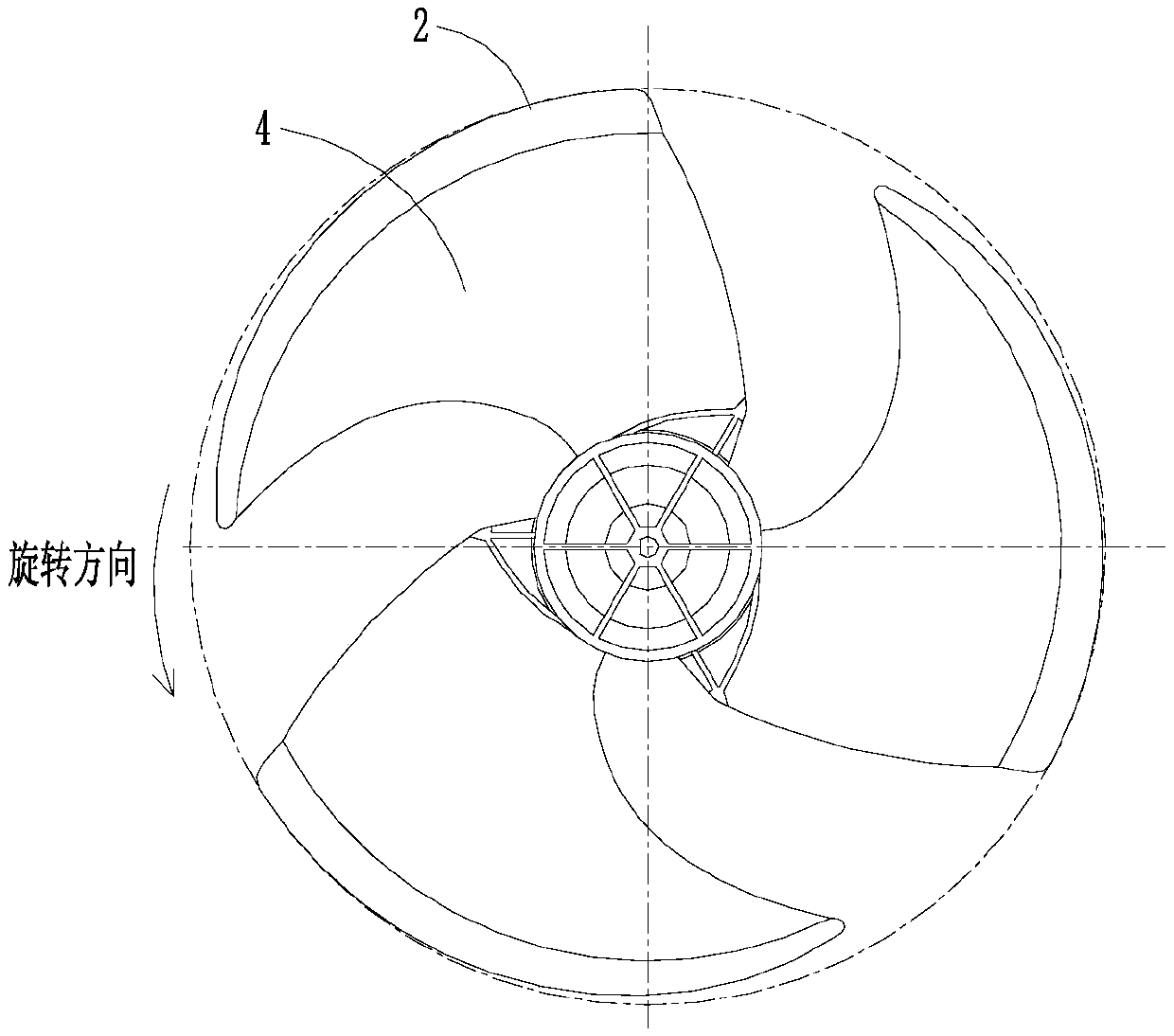

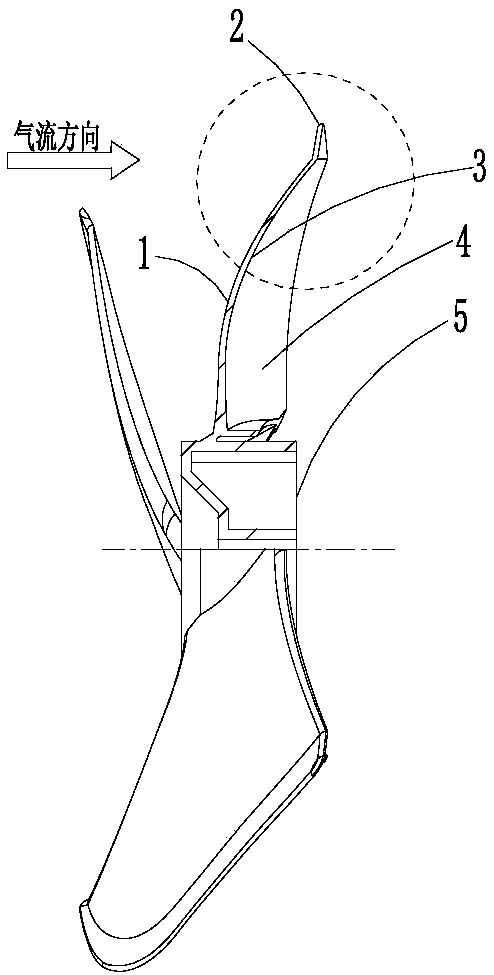

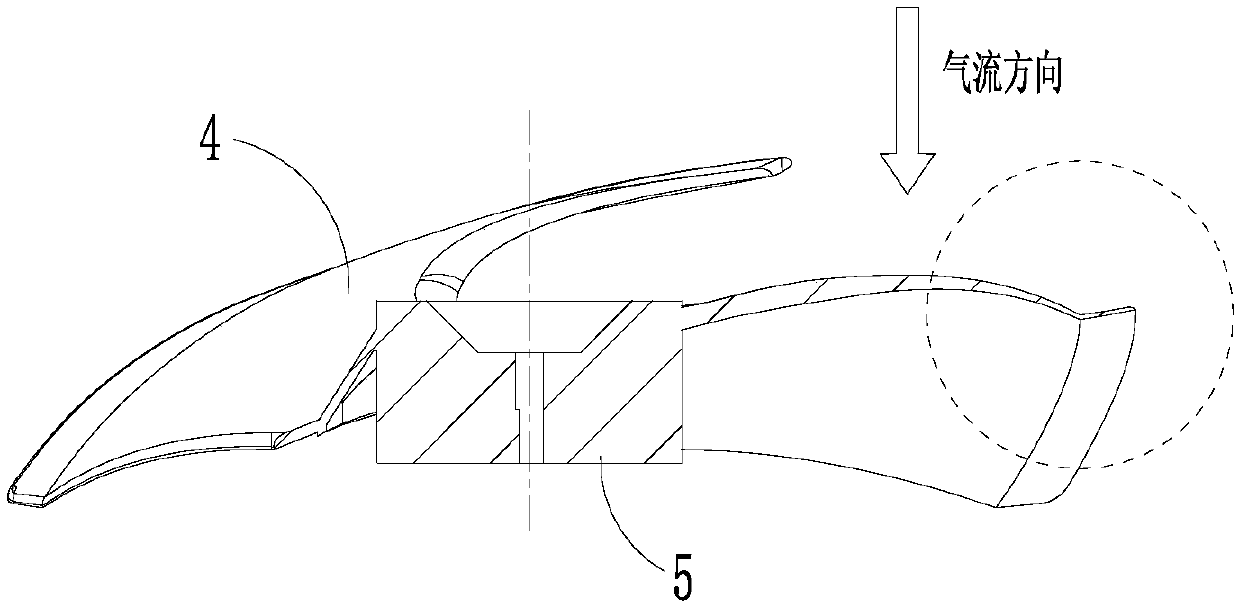

[0065] Picture 11 This is a schematic diagram of the front view structure of Embodiment 1 of this application. Picture 12 This is a schematic diagram of a side view structure of an embodiment of this application, Figure 13 This is a schematic diagram of the top view structure of Embodiment 1 of this application, Figure 14 This is a detailed structural schematic diagram of the bending of the blade top in Example 1 of this application.

[0066] As shown in the figure, the entire range of the tip 2 of the blade 4 is provided with bends to the pressure surface 3 and the suction surface 1, that is, the first side 21 and the second side 22, and the entire tip 2 is type( The upper end is the blade tip 2), or the structure with hemmed edges, is in a "Y" shape (the upper end of the Y is the blade tip 2). Among them, the first side 21 is bent to the suction surface 1 to one side to produce a structure with a bending radius of R1, thereby ensuring that the positive pressure area of th...

Embodiment 2

[0070] Figure 15 This is a schematic diagram of the front view structure of Embodiment 2 of this application. Figure 16 This is a schematic diagram of the side view structure of the second embodiment of this application, Figure 17 This is a schematic diagram of the top view structure of Embodiment 2 of this application, Figure 18 This is a detailed structural diagram of the second embodiment of the bending structure of this application, and Figure 19 This is a schematic diagram of the structure of the folding or bending area of the leaf top in the second embodiment of this application.

[0071] As shown in the figure, in the partial range of the tip 2 of the blade 4, there are bends to the pressure surface 3 and the suction surface 1 respectively, and the partial range of the tip is Figure 19 From b1 to the outermost dot of the leading edge of the blade 4, the starting position of the bend or edge along the airflow direction, the angle between the two points and the center o...

Embodiment 3

[0076] Picture 20 This is a detailed schematic diagram of the folding structure of the third embodiment of this application. As shown in the figure, the first edge 21 and the second edge 22 are respectively folded edges, wherein the angle between the first edge 21 and the blade 4 is a1, and the angle between the second edge 22 and the blade 4 is a3, the relationship between the two It is a1≤a3, or R1≤R3. The bending or hemming structure toward the pressure surface can even be approximated as a straight plate "y" (the upper end of y is the tip of the blade), that is, R3 is infinite or a3=180°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com