Test system for identifying and separating a hydrodynamic noise source and construction method thereof

A test system and hydrodynamic technology, applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems that the control measures are not targeted, affect the location and analysis of the actual ship's hydrodynamic noise source, and achieve structural The effect of simplicity, high reliability and high technology maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

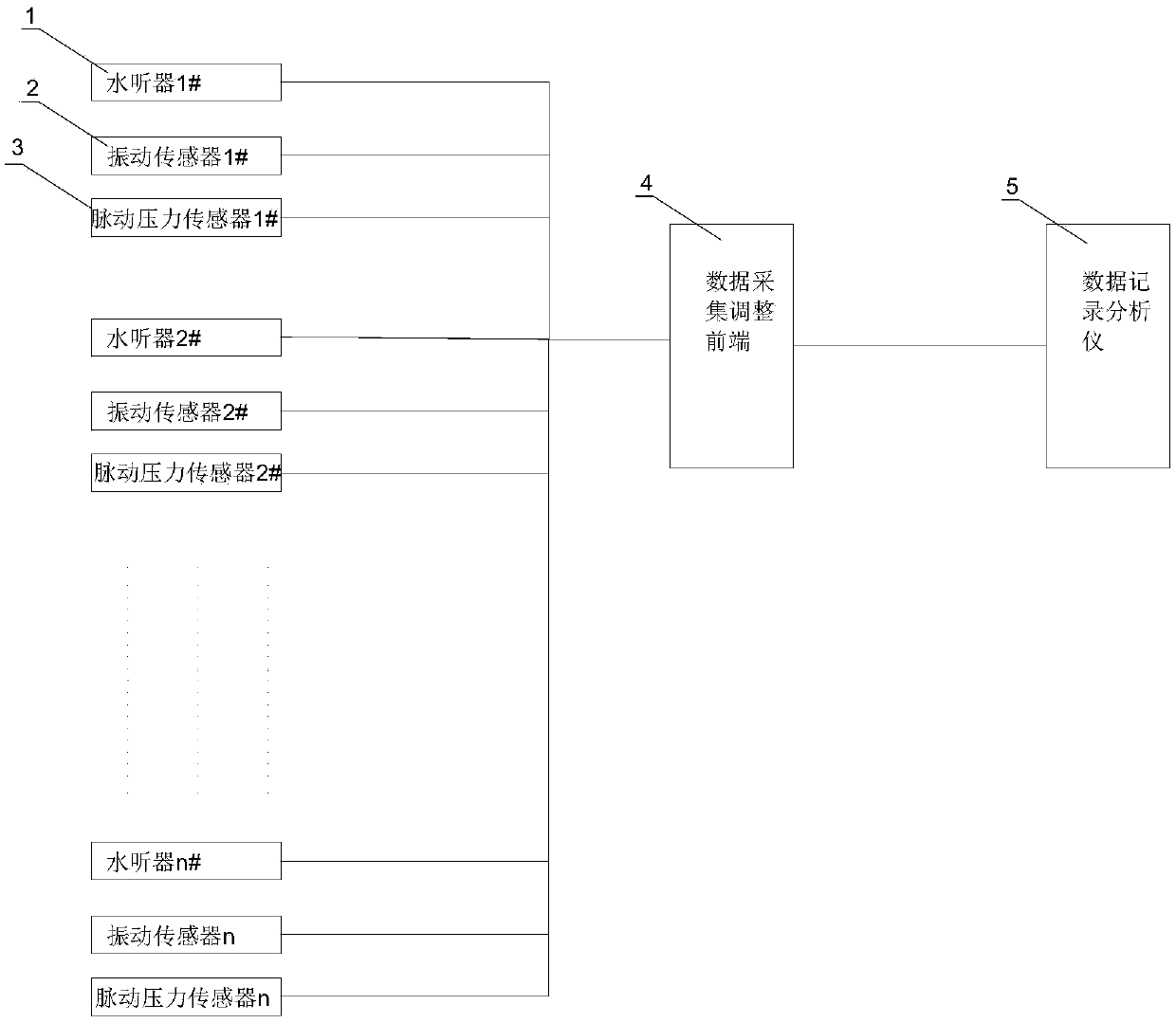

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

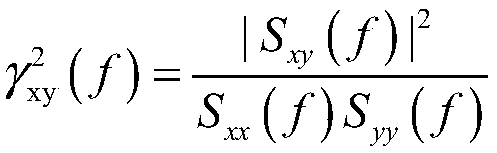

[0024] The specific noise source identification and separation of the present invention adopts the method of coherence analysis. Coherent analysis is applicable to the multi-input single-output model, which mainly analyzes the relationship between each input source and the output noise spectrum, and determines the influence of each noise source on the characteristic frequency of the output. The coherence analysis is based on the coherence function. The coherence function is a frequency domain function that indicates the internal relationship between the two functions and distinguishes the degree of correlation between the discrete components of the two signals. The size of the coherence function indicates that the output energy comes from each noise source signal energy ratio. The larger the coherence coefficient, the stronger the correlation between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com