Novel triaxial constant load compression and rheological testing machine

A rheological test, a new type of technology, applied in the direction of applying stable tension/pressure to test material strength, applying repetitive force/pulsation force to test material strength, measuring devices, etc., can solve complex negative feedback control systems that affect the use of motors Life, not a fixed value and other issues, to achieve the effect of high measurement accuracy, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

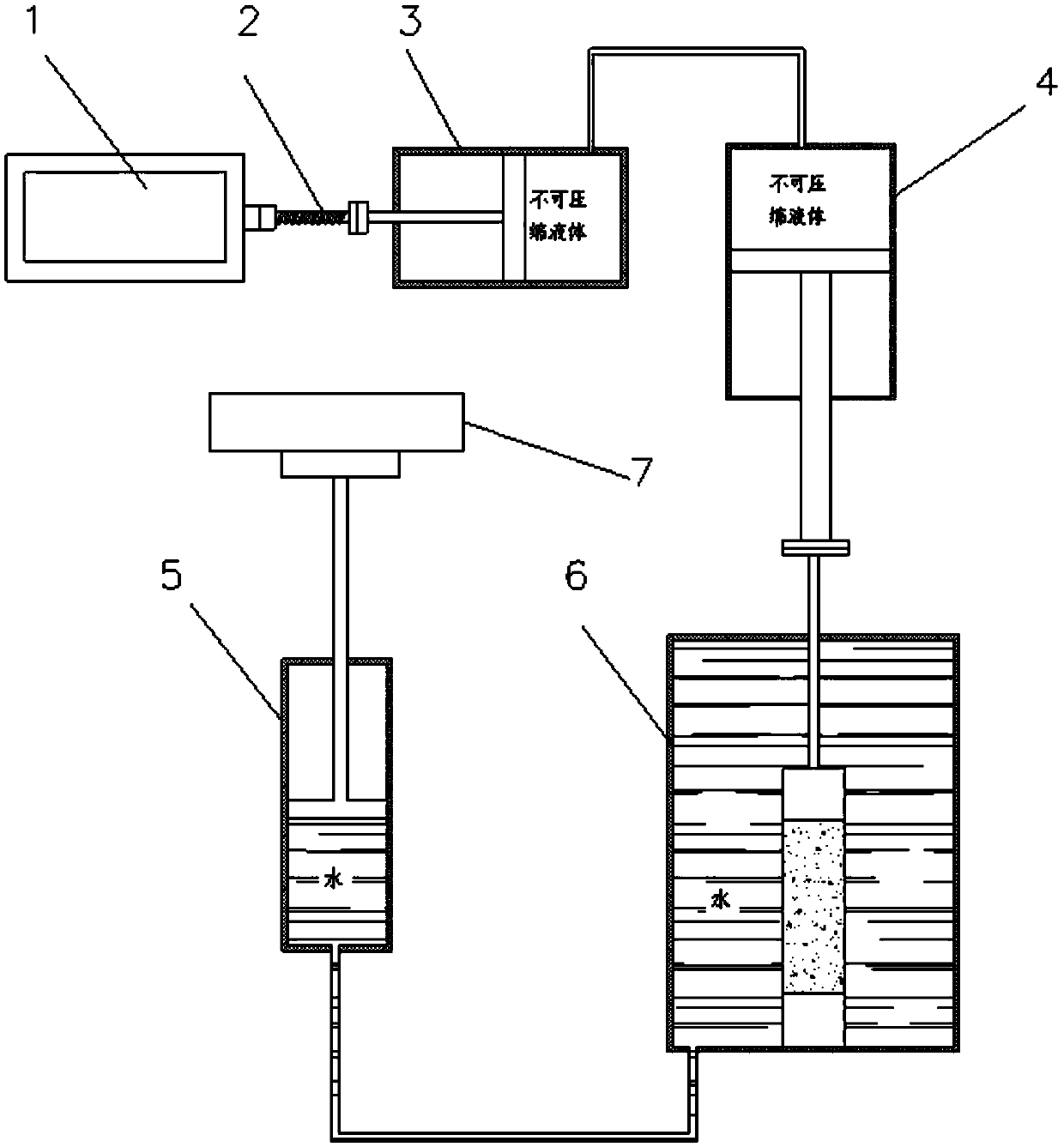

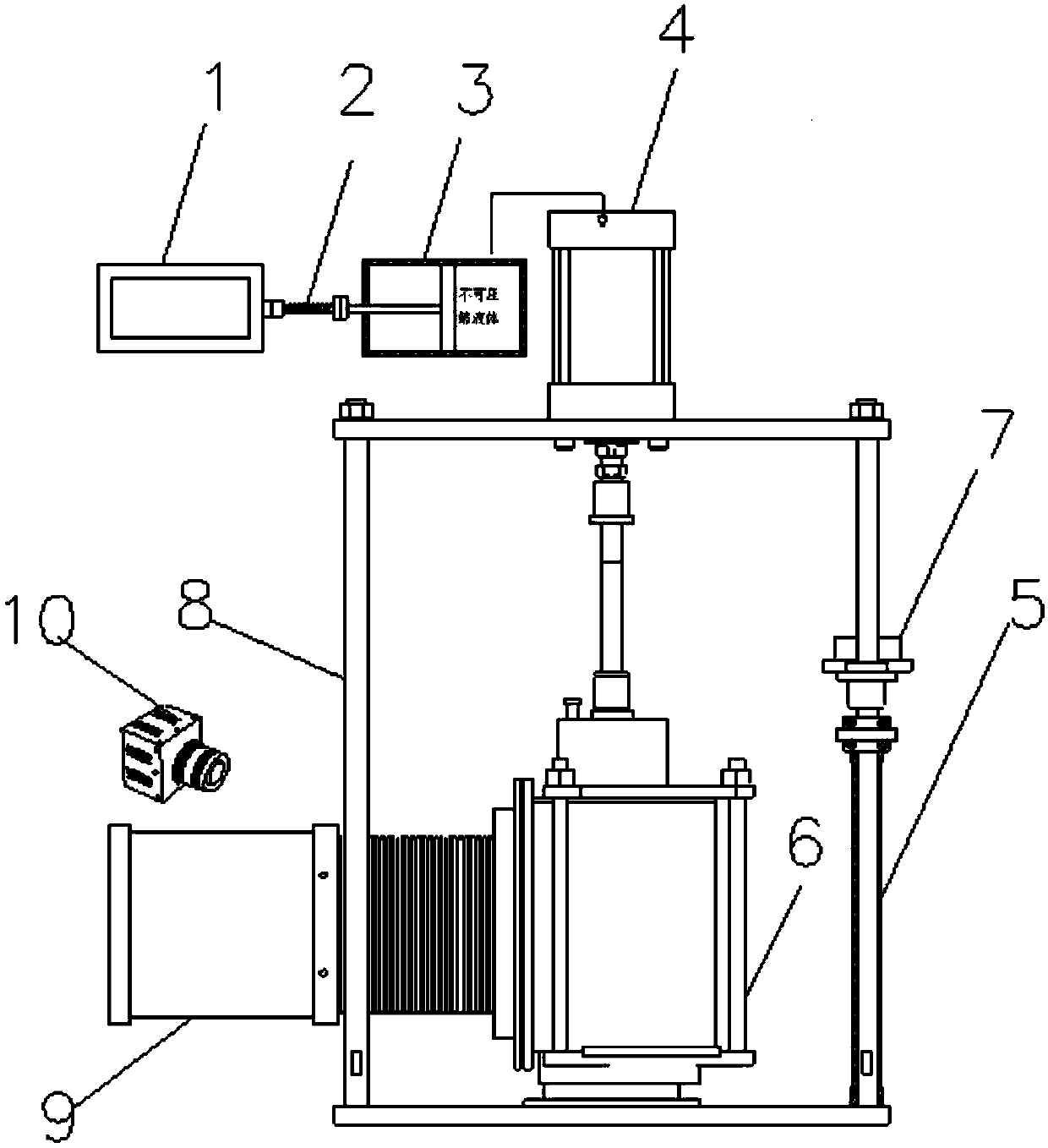

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0023] A new triaxial constant load compression and rheological testing machine can be used for triaxial constant load compression test and rheological test. The pressure of the incompressible liquid in the first piston cylinder 3 is servo-controlled by the motor to achieve the output load of the piston rod of the second piston cylinder 4, and the output load is related to the diameter of the hydraulic cylinder. The pressure of the incompressible liquid can be controlled to a certain constant value, a periodic square wave cyclic change value and a rate-controllable monotonous change value, so as to realize the triaxial test of different loading schemes.

[0024] 1. Graded rheological test

[0025] The staged rheological test is presented in the form of stepwise increase in axial load. Assuming that the primary load F1 corresponds to the pressure P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com