Motor with internal circulation heat dissipation and its forming method

A technology of internal circulation and fan, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of low heat dissipation efficiency of rotor magnet steel, loss of magnetization of rotor magnet steel, poor fan exhaust performance, etc., to reduce the risk of loss of magnetism , Stable and reliable work, strong adaptability to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

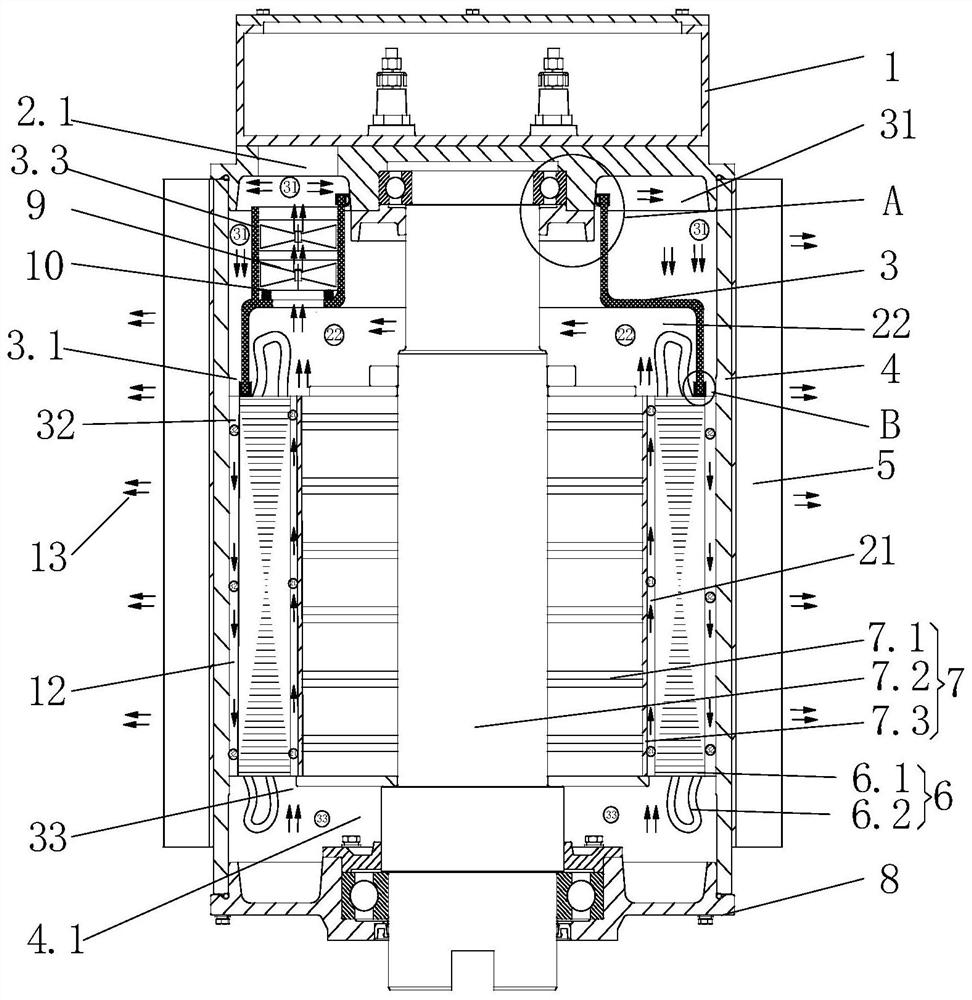

[0062] The invention provides a motor with internal circulation heat dissipation. The motor is stable and reliable, has strong application environment, good heat dissipation effect of the motor, and the magnet steel of the rotor of the motor is not easily demagnetized.

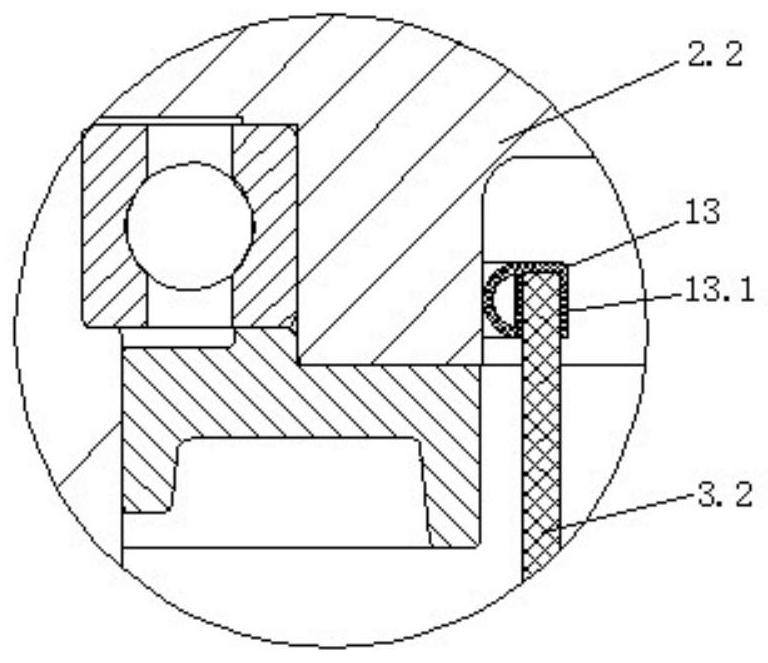

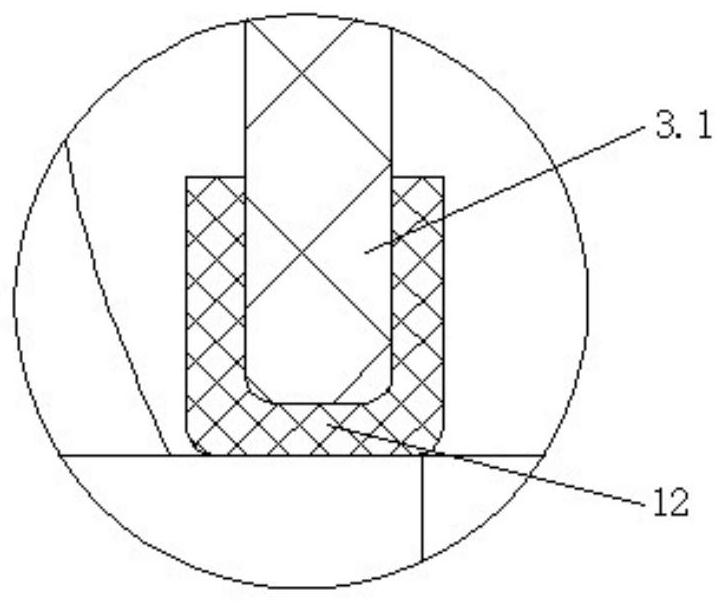

[0063] Wherein, the motor of the present invention with internal circulation heat dissipation has the following characteristics: figure 1 The structure shown includes: a housing 4 with a housing cavity 4.1, a first end cover 2 and a second end cover 8 arranged at both ends of the housing 4, a stator assembly 6 and a The fan 9 is the rotor assembly 7 arranged in the stator assembly 6 . Wherein, the stator assembly 6 can adopt the following first structure, including a stator core 6.1 and a stator winding 6.2 wound on the stator core 6.1; or, the stator assembly 6 can be other structures disclosed in the mechanical engineering handbook, and only The first structure is taken as an example for description. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com