A method for automatic control of polysilicon reduction furnace

A reduction furnace and polysilicon technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems that employees do not understand the production status of the reduction furnace, cannot adjust in time, and misdirect, so as to improve the apparent quality and reduce work volume, reducing the effect of cracks or inverted rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

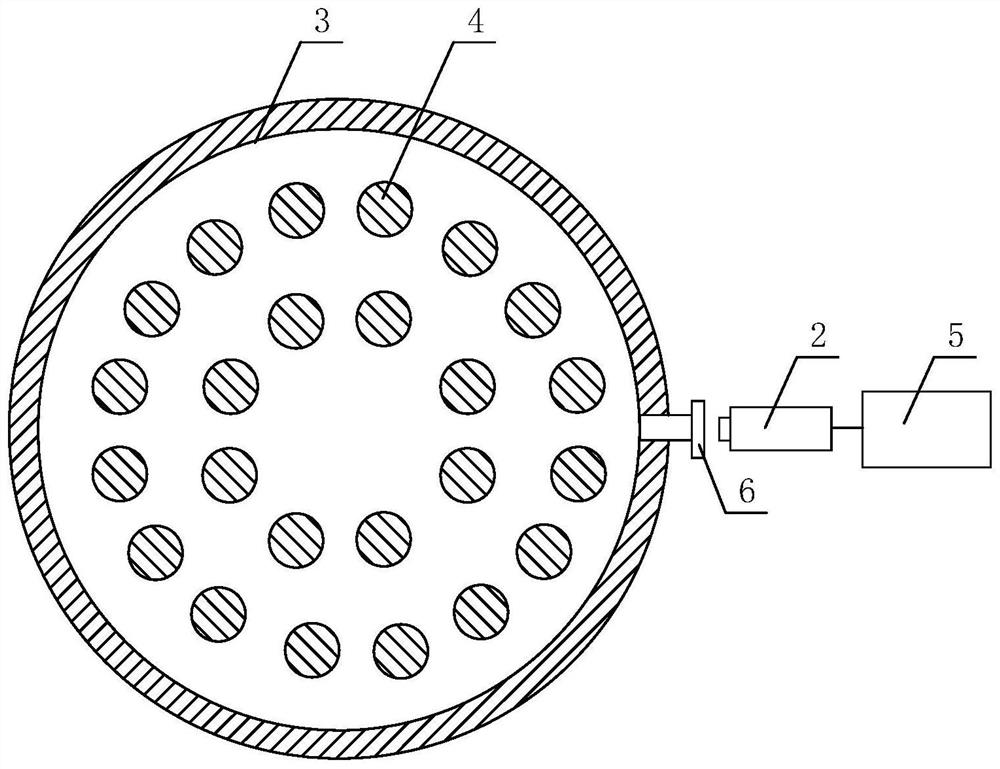

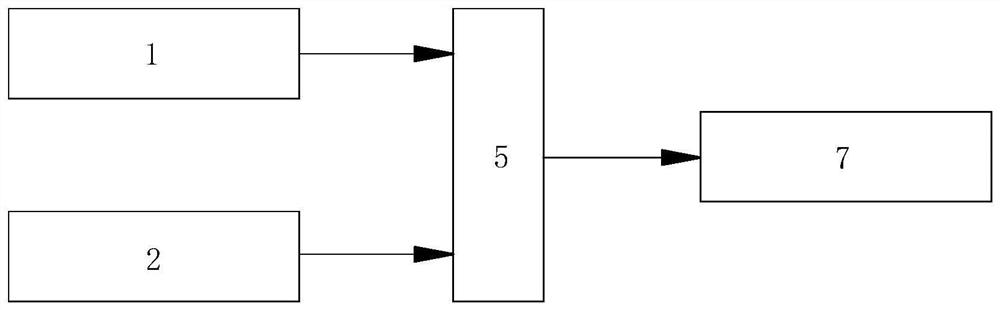

[0069] Such as figure 1 , figure 2 A polysilicon shown in the present invention is automatically controlled by the temperature measuring device 1 and the imaging device 2, and the silicon rod of the silicon rod is collected in the furnace 3, and uploaded to the industrial computer 5 for data recording, image analysis and Logic operation, obtain reductant furnace current, reducing furnace feed, and reducing furnace ratio of each time period, and control the reduction furnace actuator 7 action, realizing the temperature, reducing furnace feed amount and reducing furnace each time segment Automatic control of the ratio.

[0070] The reducing furnace temperature automatic control step is specifically:

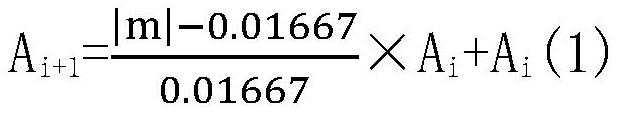

[0071] (1) After the reducing furnace is initially feed, start recording the silicon rod temperature, in practical applications, typically set to start recording silicon rod temperature after 3 minutes or 5 minutes of initial feed; initial first hour, initial current Press A 1 Average ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap