Electrode, membrane electrode assembly, electrochemical cell, stack, fuel cell, vehicle and flying object

A membrane-electrode assembly and fuel cell technology, applied in fuel cells, fuel cell additives, power system fuel cells, etc., can solve problems such as flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0066] The first embodiment relates to an electrode having a catalyst layer. exist figure 1 A schematic diagram of the electrode 100 is shown in . figure 1 The electrode 100 has a catalyst layer 10 and a support layer 20 . The support layer 20 is, for example, a moisture management layer 21 and a gas diffusion layer 22 . The moisture management layer 21 is arranged between the catalyst layer 10 and the gas diffusion layer 22 . The electrode 100 of the embodiment is suitable as an electrode for a fuel cell. Instead of the moisture management layer 21 and the gas diffusion layer 22, a layer having both moisture management and gas diffusion properties can be used.

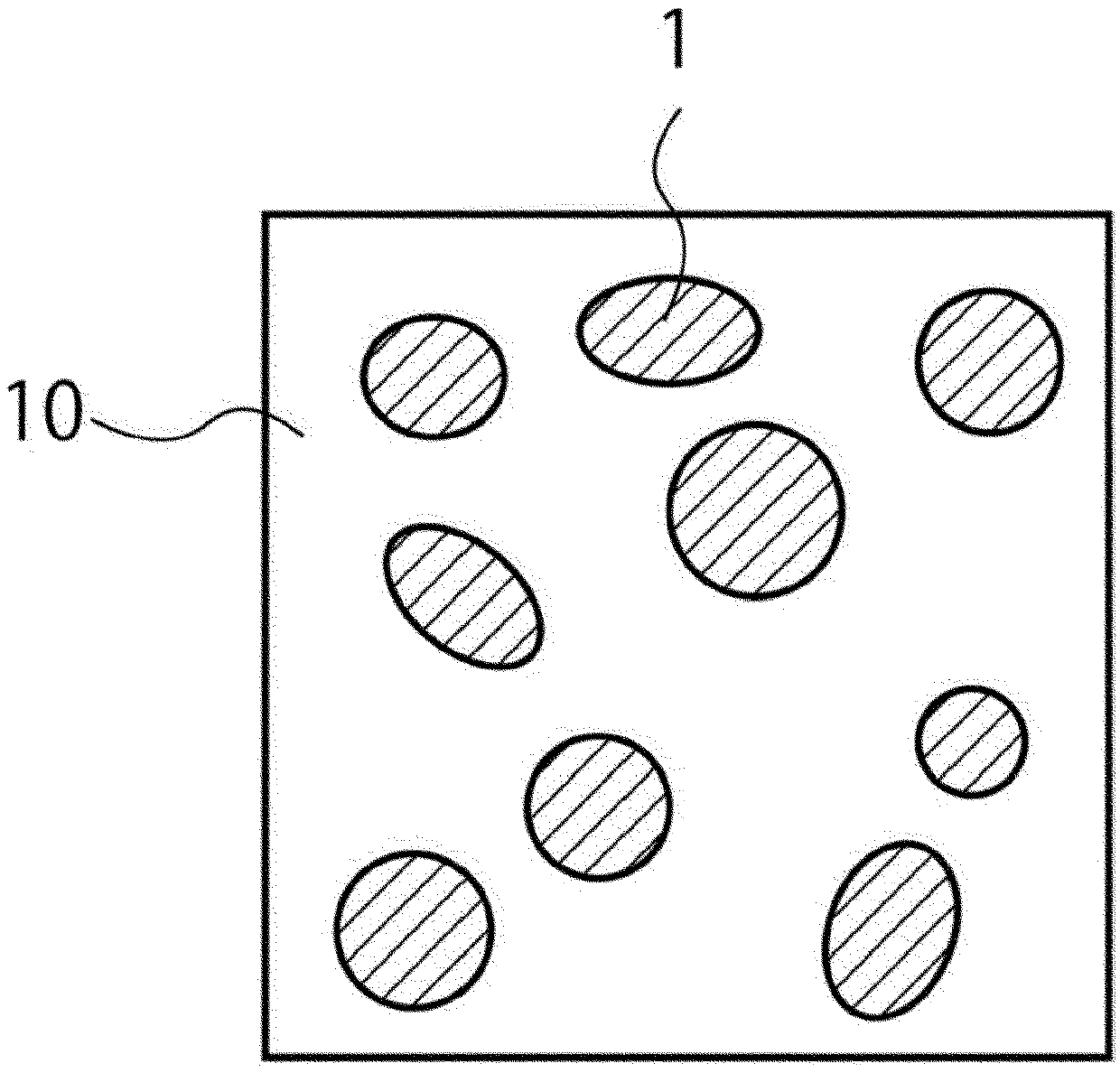

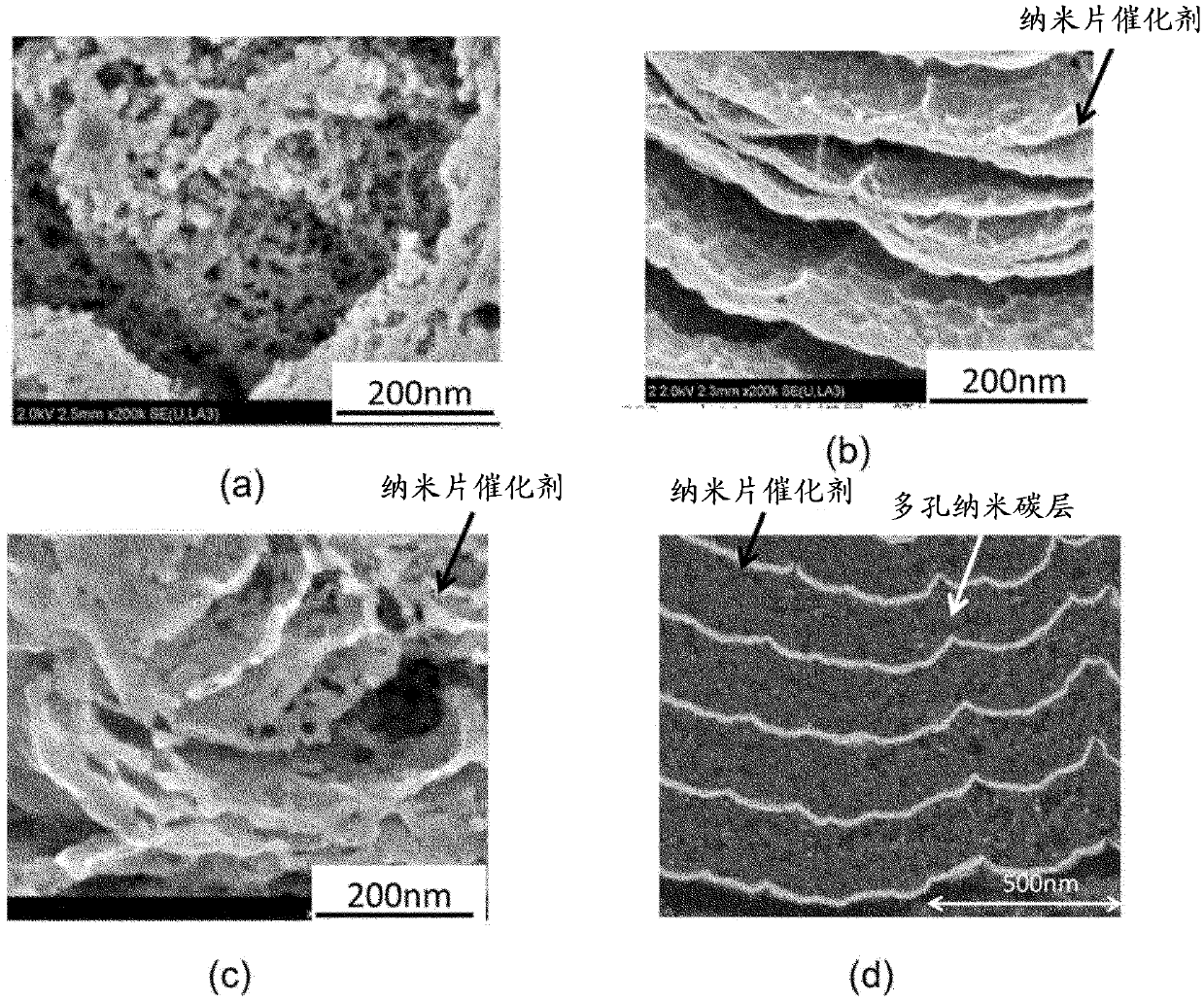

[0067]The catalyst layer 10 includes catalyst units, and pores 1 exist in the catalyst layer 10 . The catalyst unit has a porous body structure or a laminated structure. Pores 1 are present in the layered catalyst layer 10 . exist figure 2 A schematic top view of the catalyst layer 10 is shown in . like fi...

no. 2 Embodiment approach

[0097] The second embodiment relates to a membrane electrode assembly (MEA: Membrane Electrode Assembly). The MEA of the second embodiment uses the electrodes of the first embodiment. exist Figure 7 A schematic diagram of an embodiment MEA 200 is shown in . The MEA 200 has a cathode 201 , an anode 202 , and an electrolyte membrane 203 . The electrolyte membrane 203 is provided between the cathode 201 and the anode 202 . The anode 202 and the cathode 201 have a structure in which a catalyst layer and a support layer are laminated. Catalyst layers containing catalyst metals of the cathode 201 and the anode 202 exist on the electrolyte membrane side. The catalyst layer 10 in which the pores 1 exist in the electrodes of the MEA 200 faces the electrolyte membrane 203 side.

[0098] When the MEA 200 is used in a fuel cell, hydrogen is supplied to the anode 202 and air is supplied to the cathode 201 . In the cathode 201, oxygen in the air is used as a raw material, and water i...

no. 3 Embodiment approach

[0104] The third embodiment relates to an electrochemical cell. The electrochemical cell of the third embodiment uses the MEA of the second embodiment. use Figure 8 The schematic diagram of the electrochemical cell 300 shown in FIG. 1 briefly illustrates the configuration of the electrochemical cell according to this embodiment. Figure 8 The electrochemical cell 300 shown in has a cathode 201 , an anode 202 and an electrolyte membrane 203 of an MEA 200 on both sides of which are mounted current collector plates 303 , 304 and fastening plates 305 , 306 via gaskets 301 , 302 . By using the electrodes 100 and 101 of the embodiment, the electrochemical cell 300 of the embodiment maintains a moderate relative humidity while avoiding flooding, thereby improving robustness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com