LED chip soldering device

A LED chip and soldering technology, which is applied to tin feeding devices, welding equipment, metal processing equipment, etc., can solve the problem of low welding efficiency and achieve the effect of not being easy to waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

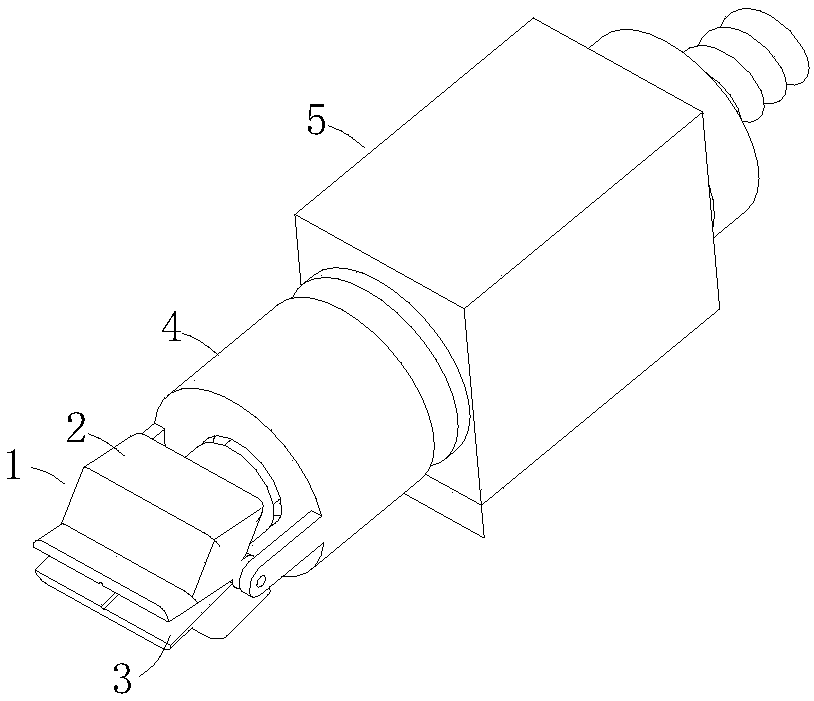

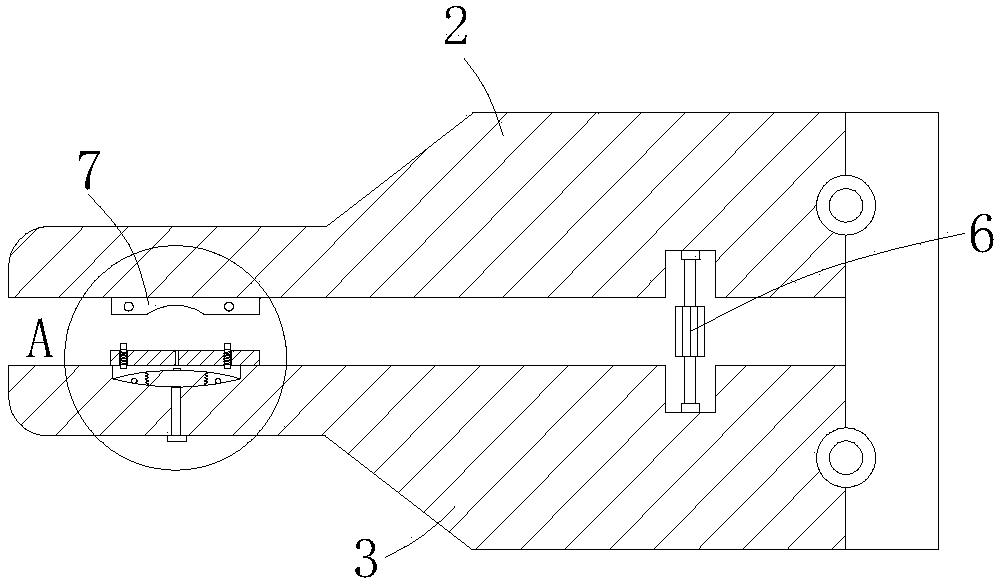

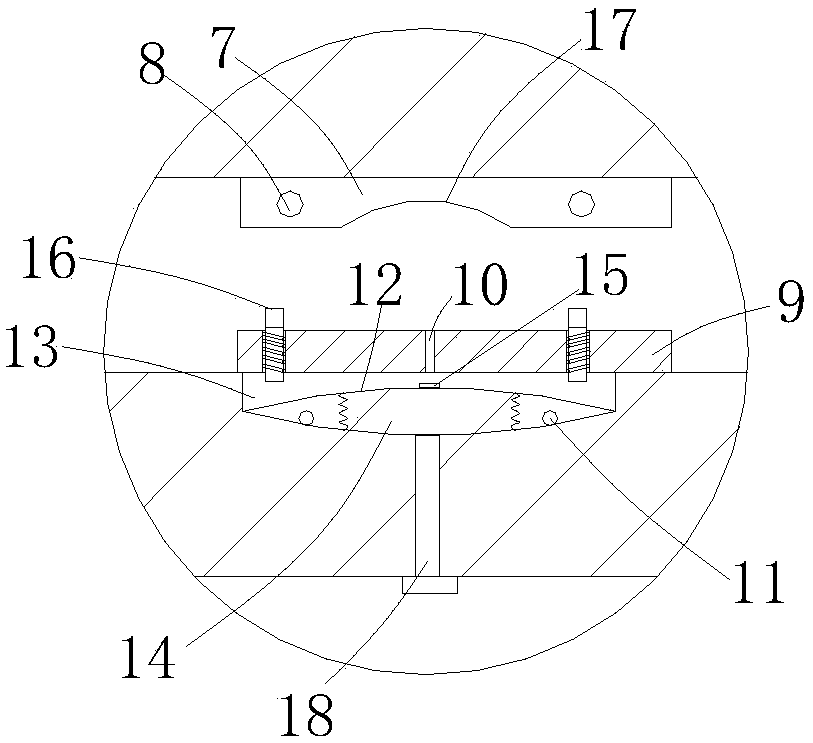

[0016] Such as Figure 1 to Figure 3 As shown, a LED chip soldering device includes a soldering chuck 1, the soldering chuck 1 is composed of an upper chuck 2 and a lower chuck 3, and the tails of the upper chuck 2 and the lower chuck 3 are movably connected with a rotating sleeve 4. The rotary sleeve 4 is connected to the rotary cylinder 5, and the clamping cylinder 6 is connected between the upper chuck 2 and the lower chuck 3. The inner surface of the upper chuck 2 is provided with a heating plate 7, and the heating wire 8 is embedded in the heating plate 7. ;

[0017] The inner surface of the lower chuck 3 is provided with a welding station 9 corresponding to the electric heating plate 7, the middle part of the welding station 9 is provided with a tin outlet hole 10, and the inside of the lower chuck 3 is provided with a tin storage chamber connected with the tin outlet hole 10. Heating wire 11 is laid on the bottom of the tin storage chamber, and an arc-shaped metal cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com