Antireflection technology for bright copper film or copper alloy film

A copper alloy and bright copper technology, applied in the direction of metal material coating process, can solve problems such as affecting the visual effect of users, and achieve the effect of uniform and continuous thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

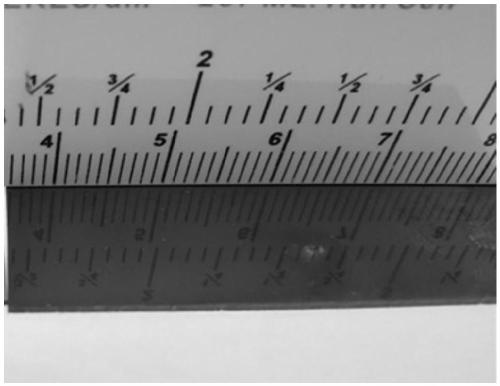

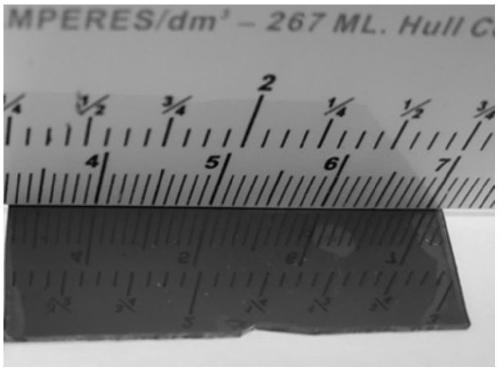

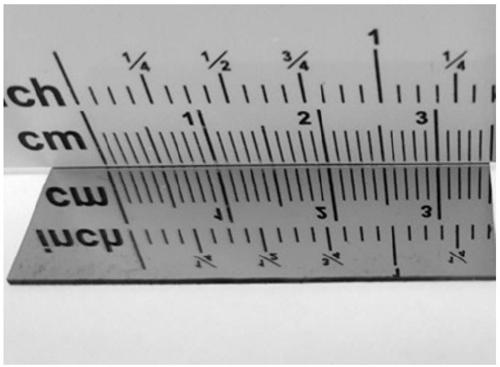

[0040] This embodiment provides a bright copper film anti-reflection process, the process includes the following steps:

[0041](1) Take a copper film test board of about 3cm×5cm, pretreat it with alkaline pretreatment potion for 60s, the treatment temperature is 50°C, and rinse it with deionized water for 1min after the pretreatment;

[0042] (2) Immerse the test panel treated in step (1) in the black oxidation treatment solution for 2 minutes, the treatment temperature is 60°C, after the black oxidation treatment, rinse with tap water and deionized water for 1 minute respectively;

[0043] (3) Immerse the test plate after the treatment in step (2) for 1 min in the corrosion inhibitor solution, the corrosion inhibitor solution is 1mmoL / L benzotriazole (BTA) solution, and the treatment temperature is normal temperature;

[0044] (4) Place the test plate treated in step (3) in an oven, bake at 100°C for 20 minutes, then move it into a desiccator to cool for 10 minutes, and take...

Embodiment 2

[0049] This embodiment provides a bright copper film anti-reflection process, the process includes the following steps:

[0050] (1) Take a copper film test board of about 3cm×5cm, pretreat it with alkaline pretreatment potion for 90s, the treatment temperature is 60°C, and rinse it with deionized water for 1min after the pretreatment;

[0051] (2) Immerse the test plate treated in step (1) in the black oxidation treatment solution for 3 minutes, the treatment temperature is 50°C, after the black oxidation treatment, rinse it with tap water and deionized water for 1 minute respectively;

[0052] (3) Immerse the test plate after the treatment in step (2) for 1 min in the corrosion-inhibiting potion, the corrosion-inhibiting potion is 1mmoL / L tolyltriazole (TTA) solution, and the treatment temperature is normal temperature;

[0053] (4) Place the test plate treated in step (3) in an oven, bake it at 150° C. for 10 minutes, then move it into a desiccator to cool for 10 minutes, a...

Embodiment 3

[0058] This embodiment provides a bright copper film anti-reflection process, the process includes the following steps:

[0059] (1) Take a copper film test board of about 3cm×5cm, pretreat it with alkaline pretreatment potion for 3 minutes, and the treatment temperature is 45°C, and rinse it with deionized water for 1 minute after the pretreatment;

[0060] (2) Immerse the test plate treated in step (1) in the black oxidation treatment solution for 0.5 min, the treatment temperature is 60°C, after the black oxidation treatment, rinse with tap water and deionized water for 1 min respectively;

[0061] (3) Immerse the test plate treated in step (2) in the corrosion inhibitor solution for 2 minutes, the corrosion inhibitor solution is 0.5mmoL / L TTA solution, and the treatment temperature is 50°C;

[0062] (4) Place the test plate treated in step (3) in an oven, bake at 200°C for 0.5 min, then move it into a desiccator to cool for 10 min, and take it out for observation and testi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com