A bright copper film or copper alloy film anti-reflection process

A copper alloy, anti-reflection technology, applied in the direction of metal material coating process, etc., can solve problems such as affecting the visual effect of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a bright copper film anti-reflection process, the process includes the following steps:

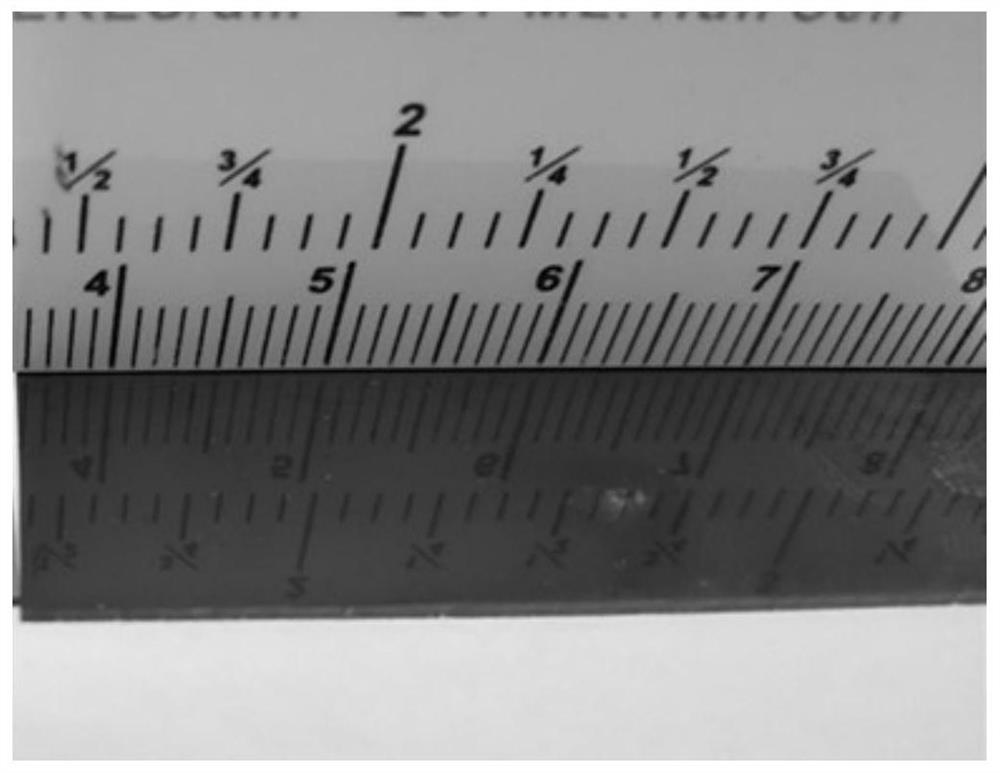

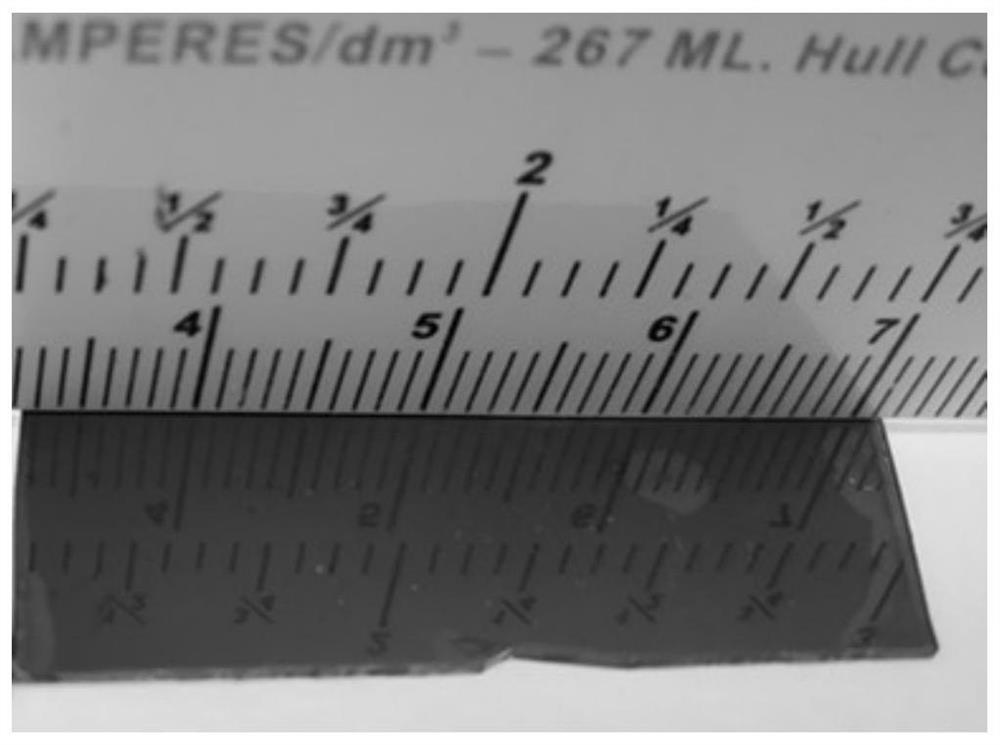

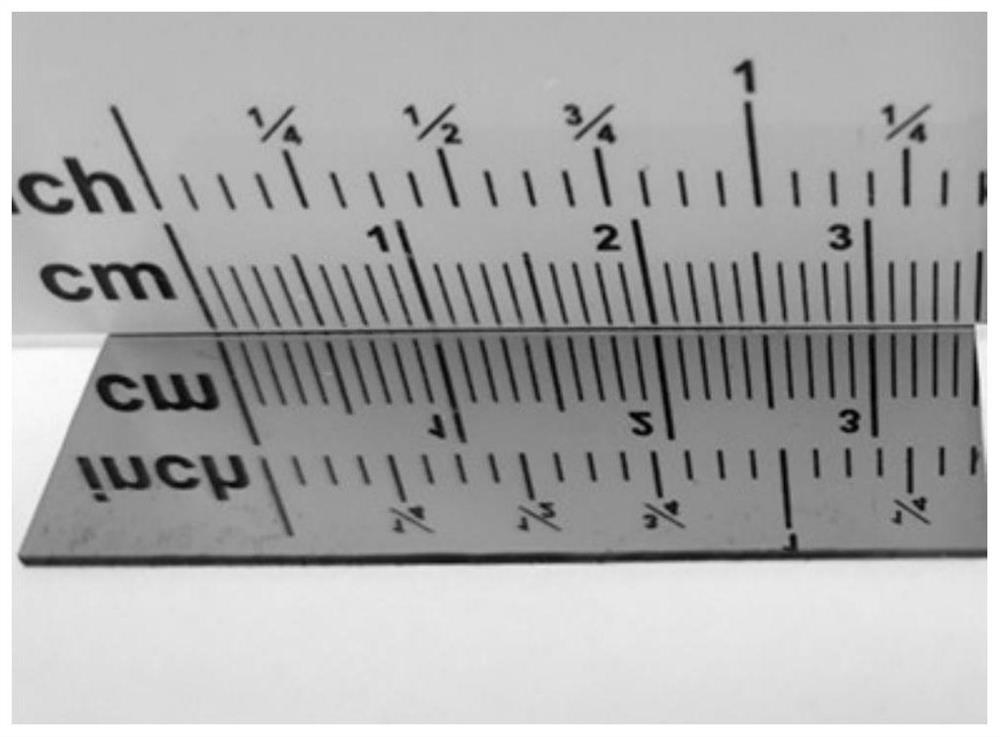

[0041](1) Take a copper film test board of about 3cm×5cm, pretreat it with alkaline pretreatment potion for 60s, the treatment temperature is 50°C, and rinse it with deionized water for 1min after the pretreatment;

[0042] (2) Immerse the test panel treated in step (1) in the black oxidation treatment solution for 2 minutes, the treatment temperature is 60°C, after the black oxidation treatment, rinse with tap water and deionized water for 1 minute respectively;

[0043] (3) Immerse the test plate after the treatment in step (2) for 1 min in the corrosion inhibitor solution, the corrosion inhibitor solution is 1mmoL / L benzotriazole (BTA) solution, and the treatment temperature is normal temperature;

[0044] (4) Place the test plate treated in step (3) in an oven, bake at 100°C for 20 minutes, then move it into a desiccator to cool for 10 minutes, and take...

Embodiment 2

[0049] This embodiment provides a bright copper film anti-reflection process, the process includes the following steps:

[0050] (1) Take a copper film test board of about 3cm×5cm, pretreat it with alkaline pretreatment potion for 90s, the treatment temperature is 60°C, and rinse it with deionized water for 1min after the pretreatment;

[0051] (2) Immerse the test plate treated in step (1) in the black oxidation treatment solution for 3 minutes, the treatment temperature is 50°C, after the black oxidation treatment, rinse it with tap water and deionized water for 1 minute respectively;

[0052] (3) Immerse the test plate after the treatment in step (2) for 1 min in the corrosion-inhibiting potion, the corrosion-inhibiting potion is 1mmoL / L tolyltriazole (TTA) solution, and the treatment temperature is normal temperature;

[0053] (4) Place the test plate treated in step (3) in an oven, bake it at 150° C. for 10 minutes, then move it into a desiccator to cool for 10 minutes, a...

Embodiment 3

[0058] This embodiment provides a bright copper film anti-reflection process, the process includes the following steps:

[0059] (1) Take a copper film test board of about 3cm×5cm, pretreat it with alkaline pretreatment potion for 3 minutes, and the treatment temperature is 45°C, and rinse it with deionized water for 1 minute after the pretreatment;

[0060] (2) Immerse the test plate treated in step (1) in the black oxidation treatment solution for 0.5 min, the treatment temperature is 60°C, after the black oxidation treatment, rinse with tap water and deionized water for 1 min respectively;

[0061] (3) Immerse the test plate treated in step (2) in the corrosion inhibitor solution for 2 minutes, the corrosion inhibitor solution is 0.5mmoL / L TTA solution, and the treatment temperature is 50°C;

[0062] (4) Place the test plate treated in step (3) in an oven, bake at 200°C for 0.5 min, then move it into a desiccator to cool for 10 min, and take it out for observation and testi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com