Preparation method of antireflection oxide surface

An oxide and anti-reflection technology, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, solid-state diffusion coating, etc., can solve the problems of complicated and harsh manufacturing process, great impact on the anti-reflection effect of the film layer, and low value , to achieve the effects of improving measurement accuracy, excellent anti-reflection performance, and uniform and continuous thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Take a piece of bright copper sheet with a size of about 10mmх10mm, treat it with a pretreatment cleaning agent for 10min, the treatment temperature is 20℃, and rinse it with deionized water for 1min after the pretreatment;

[0040] (2) at 20-30° C., use 2000-mesh sandpaper to polish the copper sheet pretreated in step (1);

[0041] (3) Weigh 7.5g of ferric chloride, pour it into 50ml of deionized water and stir until it is completely dissolved, then add 3ml of hydrochloric acid and 100ml of deionized water in turn, after the etching solution is successfully prepared, soak it at 20-50°C Or spray the polished copper sheet in step (2) for 10-60min etching treatment in liquid medicine, and then wash it with water;

[0042] (4) The copper sheet processed in step (3) was placed in a corundum boat, placed in a muffle furnace, thermally oxidized at 500° C. for 120 min, cooled in the furnace after the treatment, and taken out for observation and testing.

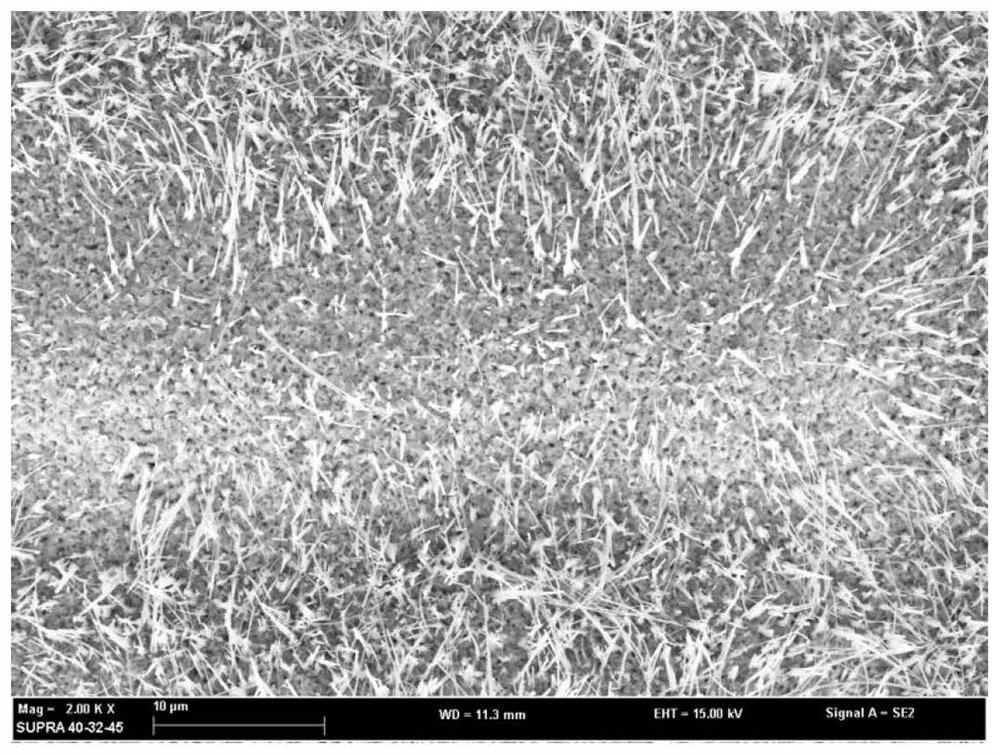

[0043] like Fi...

Embodiment 2

[0046] (1) Take a bright copper sheet with a size of about 10mmх10mm, treat it with a pretreatment cleaning agent for 10min, the treatment temperature is 20℃, and rinse it with deionized water for 1min after the pretreatment;

[0047] (2) at 20-30° C., use 2000-mesh sandpaper to polish the copper sheet pretreated in step (1);

[0048] (3) Weigh 7.5g of ferric chloride, pour it into 50ml of deionized water and stir until it is completely dissolved, then add 3ml of hydrochloric acid and 100ml of deionized water in turn, after the etching solution is successfully prepared, soak it at 20-50°C Or spray the polished copper sheet in step (2) for 10-60min etching treatment in liquid medicine, and then wash it with water;

[0049] (4) The copper sheet processed in step (3) was placed in a corundum boat, placed in a muffle furnace, thermally oxidized at 500° C. for 60 min, cooled in the furnace after the treatment, and taken out for observation and testing.

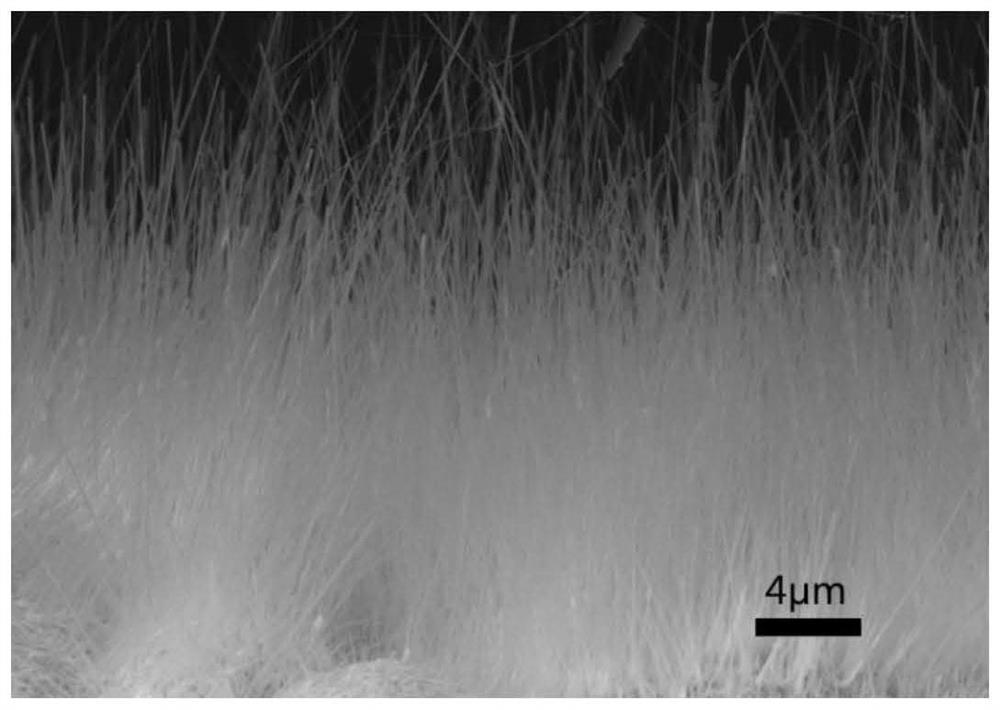

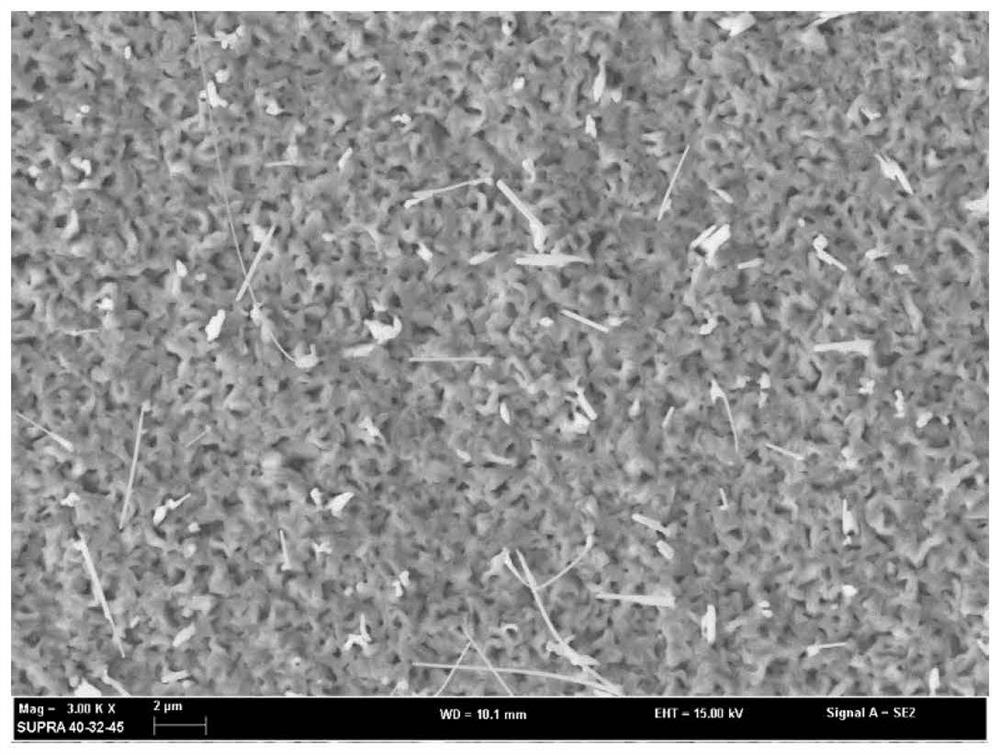

[0050] like Figure 5 As ...

Embodiment 3

[0053] (1) Take a bright copper sheet with a size of about 10mmх10mm, treat it with a pretreatment cleaning agent for 10min, the treatment temperature is 20℃, and rinse it with deionized water for 1min after the pretreatment;

[0054] (2) at 20-30° C., use 2000-mesh sandpaper to polish the copper sheet pretreated in step (1);

[0055] (3) Weigh 7.5g of ferric chloride, pour it into 50ml of deionized water and stir until it is completely dissolved, then add 3ml of hydrochloric acid and 100ml of deionized water in turn, after the etching solution is successfully prepared, soak it at 20-50°C Or spray the polished copper sheet in step (2) for 10-60min etching treatment in liquid medicine, and then wash it with water;

[0056] (4) The copper sheet processed in step (3) was placed in a corundum boat, placed in a muffle furnace, thermally oxidized at 450° C. for 180 min, cooled in the furnace after the treatment, and taken out for observation and testing.

[0057] like Figure 5 As...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water droplet contact angle | aaaaa | aaaaa |

| Water droplet contact angle | aaaaa | aaaaa |

| Water droplet contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com