Energy-saving electric boiler

A technology of electric boilers and boiler devices, which is applied in the field of electric boilers, can solve the problems of high energy consumption and shorten the service life of electric boilers, and achieve the effects of saving energy consumption, improving water heating efficiency, and increasing heat preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

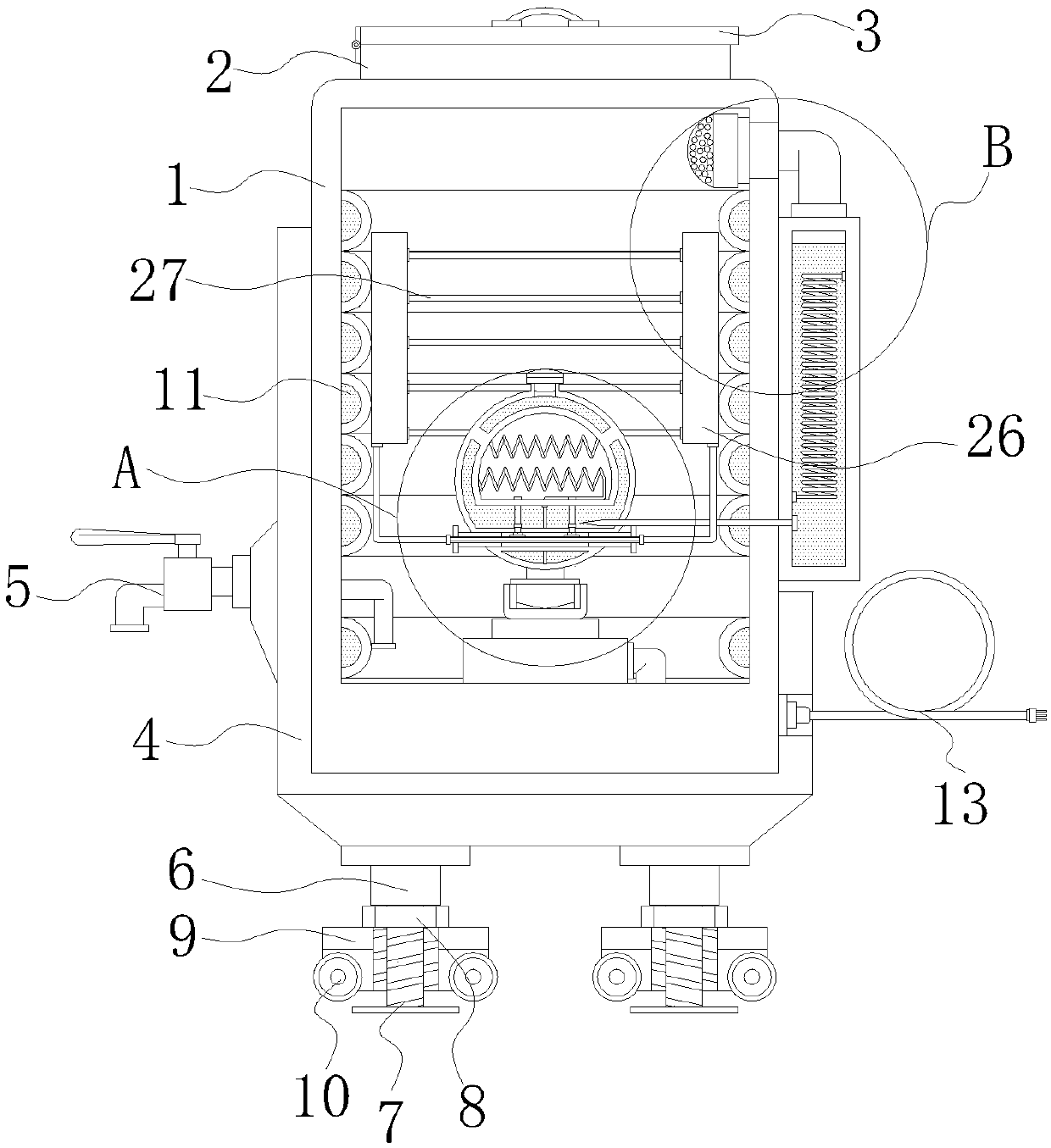

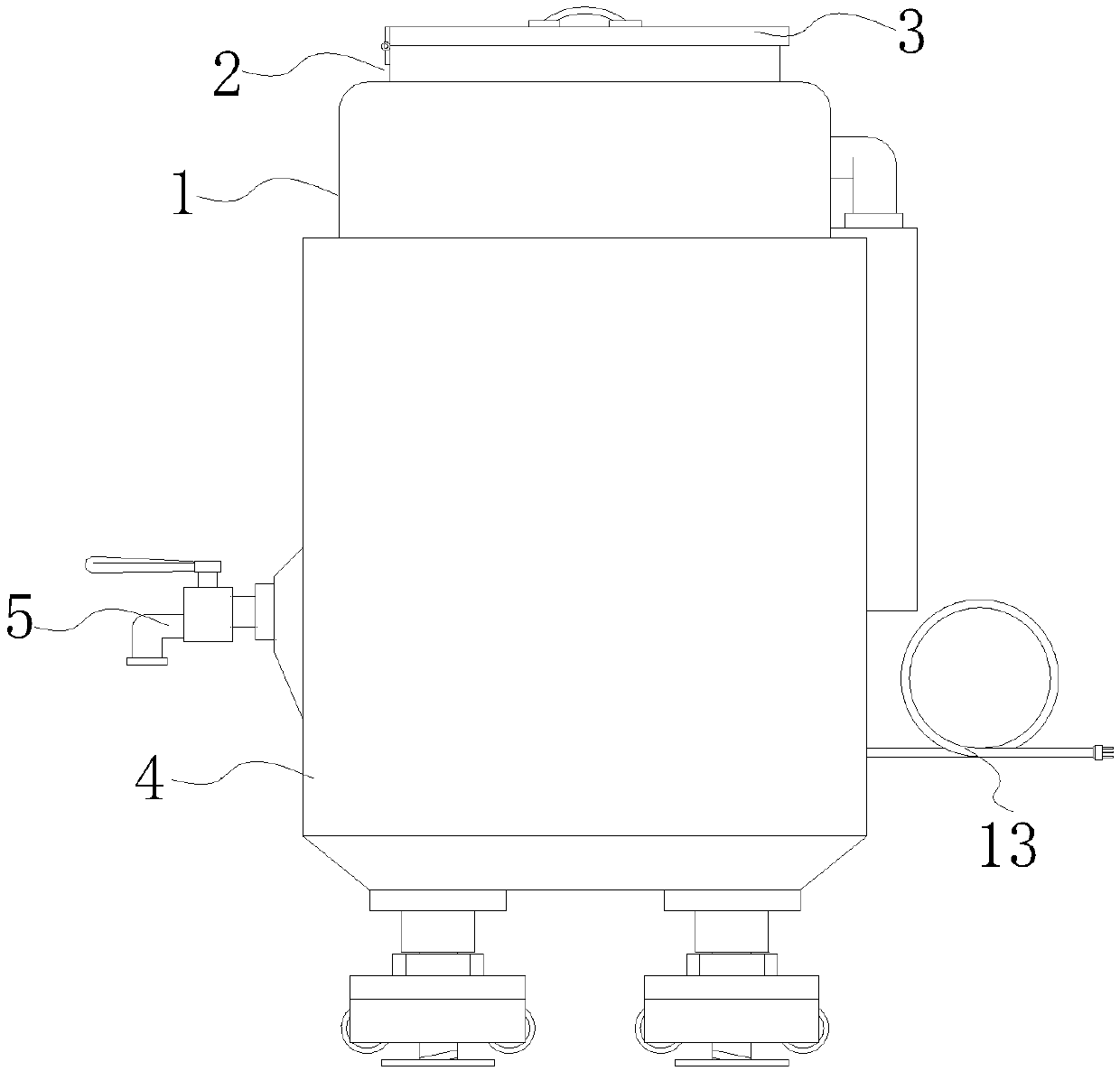

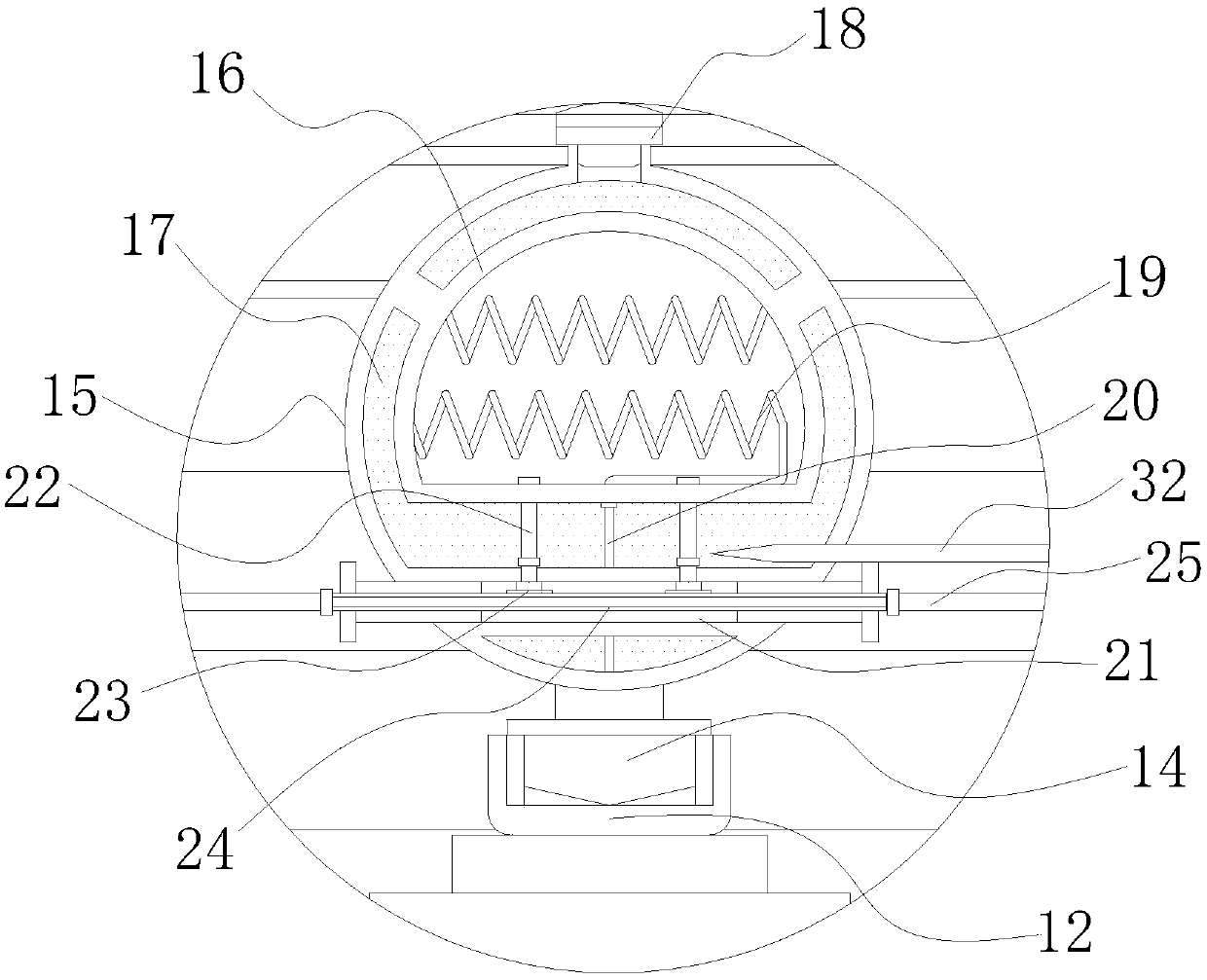

[0026] Such as Figure 1-4As shown, the embodiment of the present invention provides an energy-saving electric boiler, which includes a boiler device 1. The upper part of the boiler device 1 includes a water inlet 2 and a thermal insulation top cover 3. The water inlet 2 is opened on the top of the boiler device 1. The thermal insulation top cover 3 One side of the bottom is hinged to one side of the top of the water inlet 2, so that water can be poured into the interior of the boiler device 1 through the water inlet 2, and the exterior of the boiler device 1 includes an insulation jacket 4, and the inner wall of the insulation jacket 4 is connected to the boiler The outer side of the device 1 is socketed, so that the heat preservation tube 4 can ensure that the heat inside the boiler device 1 will not be lost quickly. Inserting, one end of the faucet 5 runs through the left side of the insulation jacket 4 and extends to the inside of the boiler device 1, the inner cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com