Heat exchange device

A technology of heat exchange device and heat exchange tube, which is applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of large heat exchange area, poor exchange effect, limited heat exchange area, etc. Achieve the effect of large heat exchange area, tight arrangement and sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples only represent one or several best implementation modes, and should not be construed as limiting the present invention.

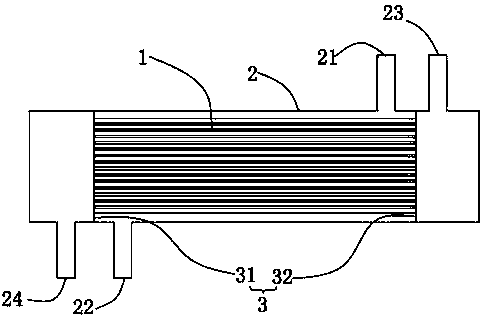

[0022] Such as Figure 1 to Figure 3 As shown, the heat exchange device provided by the invention comprises:

[0023] Heat exchange tubes for isolating waste hot water and clean water and transferring the heat of waste hot water to clean water 1,

[0024] Housing for containing waste hot water and clean water 2,

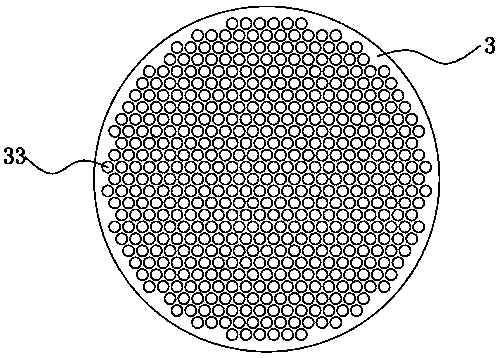

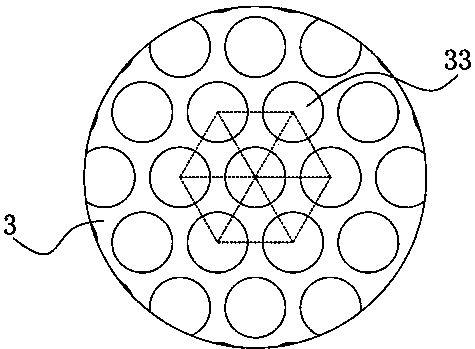

[0025] And the fixing plate 3 for fixing the heat exchange tube 1 in the housing 2 , there are two fixing plates 3 , namely the first fixing plate 31 and the second fixing plate 32 .

[0026] The inside of the housing 2 is hollow, and the housing 2 is also provided with a clean water inlet pipe 21 , a clean water outlet pipe 22 , a waste hot water inlet pipe 23 and a waste hot water outlet pipe 24 .

[0027] The fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com