Artificial core small batch production device

A technology for making devices and artificial cores, which is applied in the preparation and sampling of measuring devices, samples for testing, etc., can solve the problems of high density, less core volume, and low strength, and achieves strong practicability and high efficiency. Easy, eliminates the effect of experimental error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

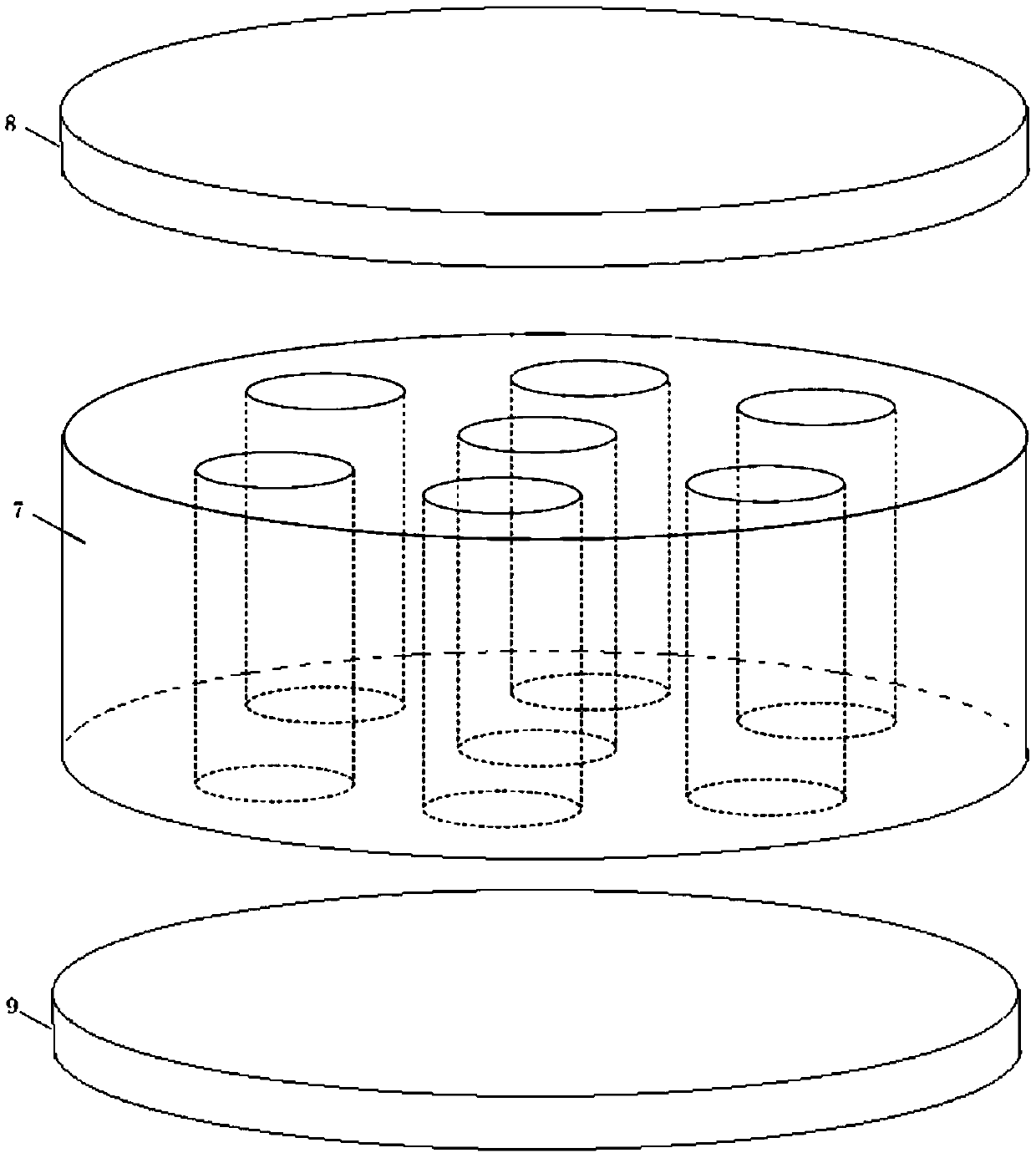

[0018] The present invention is further illustrated by taking a seven-hole core bin holder as an example. In practical applications, rock core bin holders with different numbers of holes and holes with different diameters can be provided.

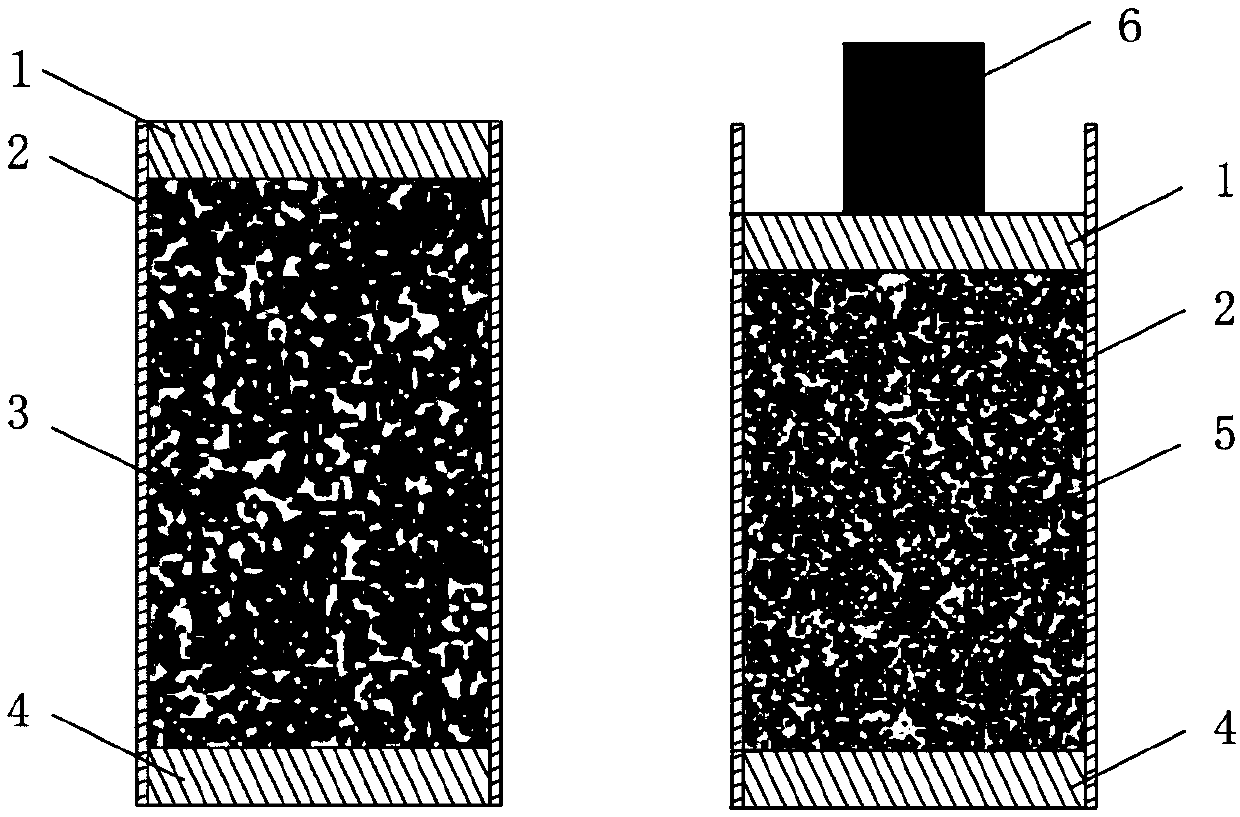

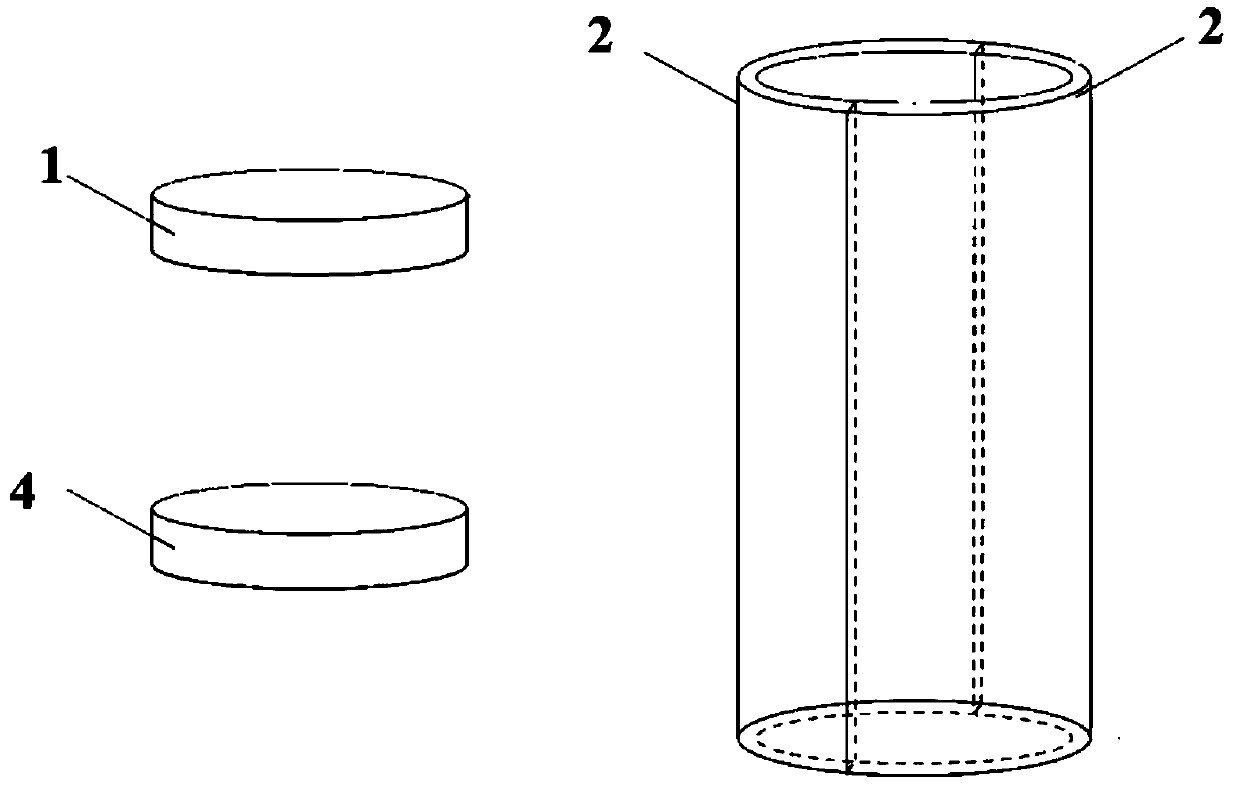

[0019] A small-batch production device for artificial rock cores includes a core bin, a core bin holder 7, a top plate 8, a bottom backing plate 9, and an indenter 6. The core bin is installed in the core bin holder 7, and the core bin holds The device 7 is provided with a plurality of holes for installing the core bin, the bottom backing plate 9 is installed on the bottom of the core bin holder 7, the top plate 1 is equipped with a pressure head 6, and the upper end of the pressure head 6 is connected to the top pressure plate 8.

[0020] The core chamber also includes a bottom plate 4 and a sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com