Method for testing pressure bearing capacity of oil well cement lightening admixture

A technology of oil well cement and pressure bearing capacity, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., which can solve the problem that the test of the pressure bearing capacity of the lightening agent is not unified, so as to ensure the safety of cementing construction , to ensure stable performance and improve the effect of cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

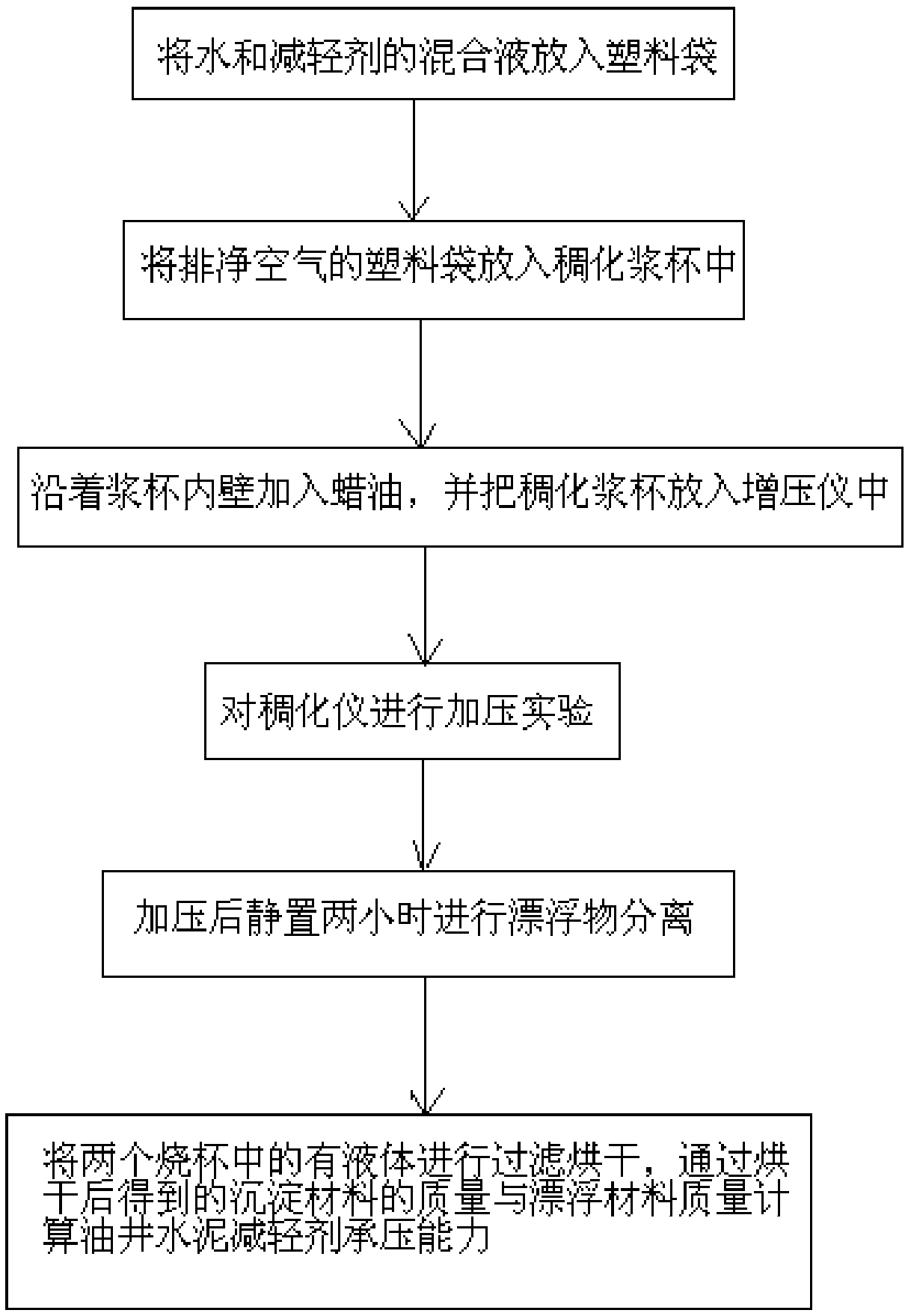

[0018] A method for testing the pressure bearing capacity of an oil well cement lightening agent, such as figure 1 shown, including the following steps:

[0019] 1) Weigh a certain amount of water and lightening agent, and pour the mixed liquid into a plastic bag after fully stirring;

[0020] 2) Drain and seal the air in the plastic bag, and put the plastic bag containing the mixed liquid into the thickened pulp cup;

[0021] 3) Slowly add paraffin oil along the inner wall of the pulp cup, and put the pulp cup into the pressurized thickener;

[0022] 4) Carry out a pressurization experiment on the thickener, and take out the slurry cup after holding the pressure for two hours;

[0023] 5) Pour the mixed liquid in the plastic bag of the slurry cup into the prepared beaker, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com