Non-contact voltage recording device, system and method

A non-contact, voltage technology, applied in the direction of measuring device, only measuring voltage, signal transmission system, etc., can solve the problems such as time-consuming and energy-consuming of testers, high wiring risk, short circuit of voltage transformer, etc., to improve efficiency and improve efficiency. Safety, immunity from electromagnetic interference, and the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

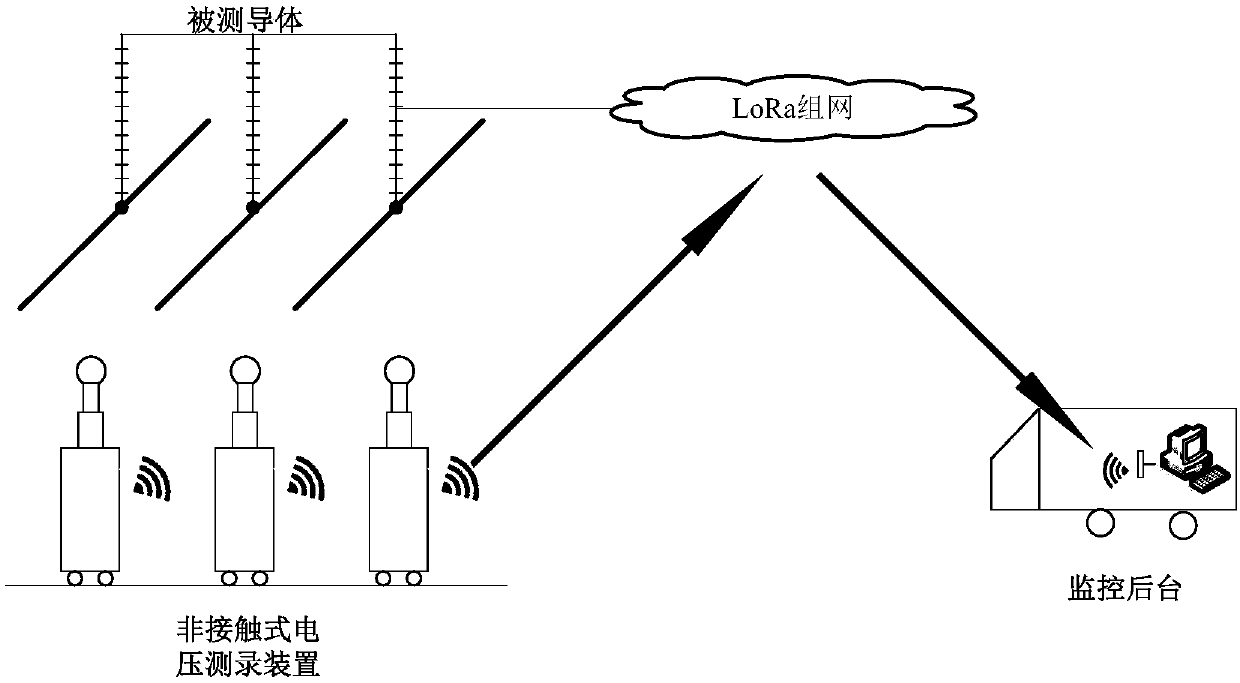

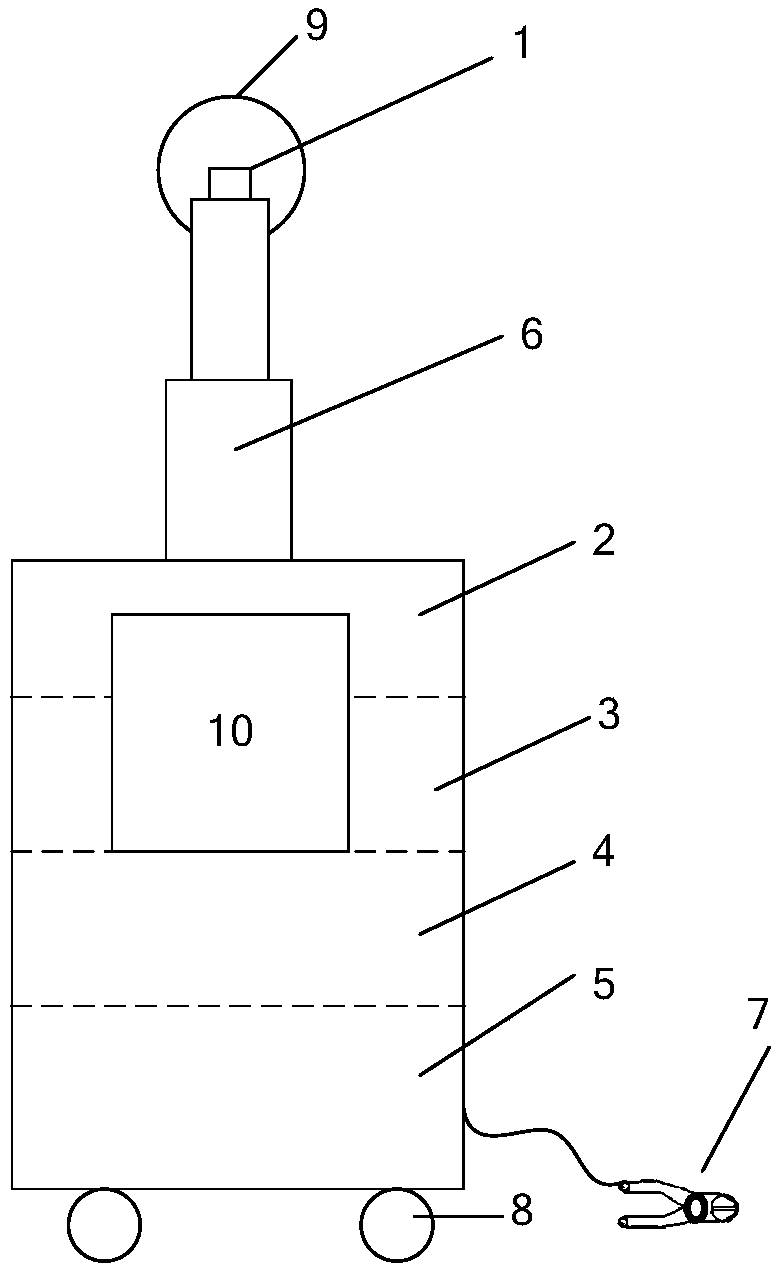

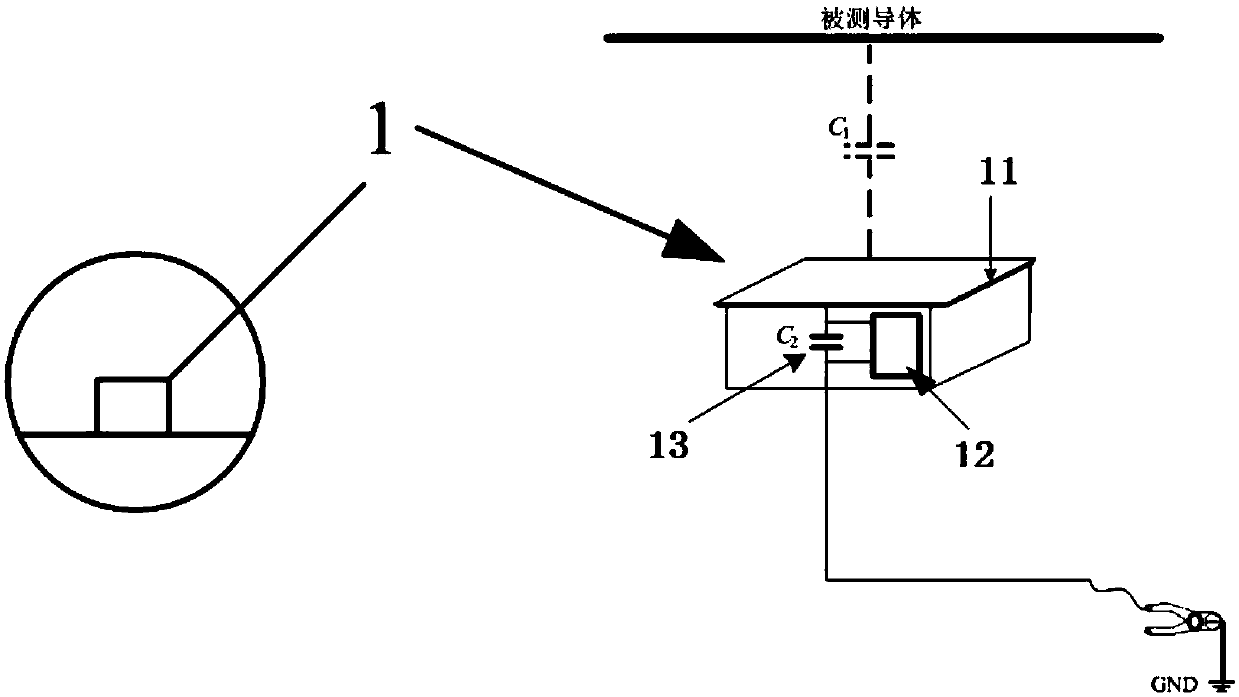

[0020] A kind of non-contact voltage recording system described in the present invention, such as figure 1 As shown, including the measured conductor, non-contact voltage recording device and monitoring background. One non-contact voltage recording device can measure one-phase voltage, and three devices are needed to test three-phase voltage. The device is movable. During the measurement process, the non-contact voltage recording device is placed directly under the measured conductor, and the height and voltage division ratio of the device are adjusted according to the measured voltage level, and the space electric field effect is used to measure the transformer or transmission. The transient voltage signal of the line, and the transient signal is sent to the wireless monitoring background after being saved locally. The moni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com