A hot rolled plate convexity prediction method based on data driving

A data-driven, predictive method technology, applied in neural learning methods, electrical digital data processing, special data processing applications, etc., can solve problems such as economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

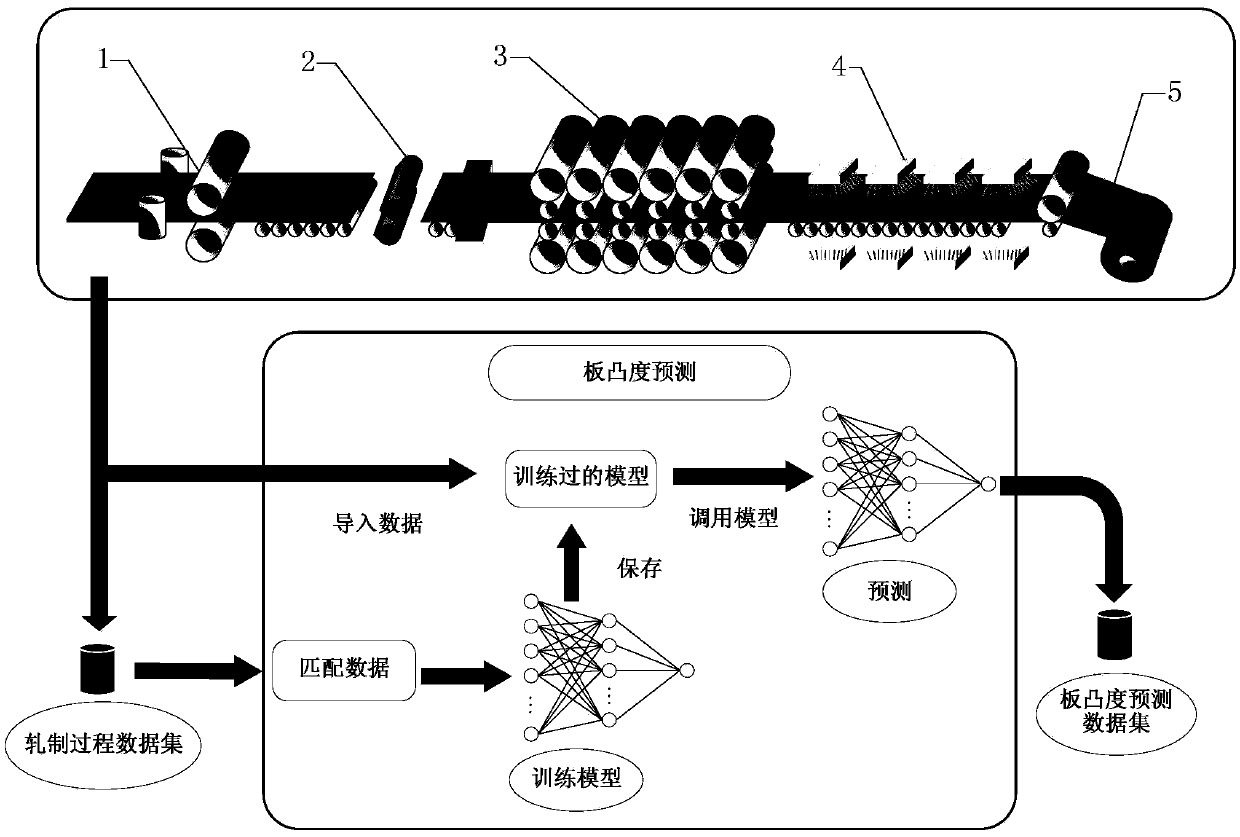

[0049] In this embodiment, the data-driven hot-rolled sheet convexity prediction method combined with the production line structure is as follows figure 1 As shown, the data of the hot continuous rolling production line composed of six HCw rolling mills are used. The diameter of the roll is 630mm-700mm, the width of the rollable strip is 700mm-2130mm, and the thickness is 1.2mm-25.4mm.

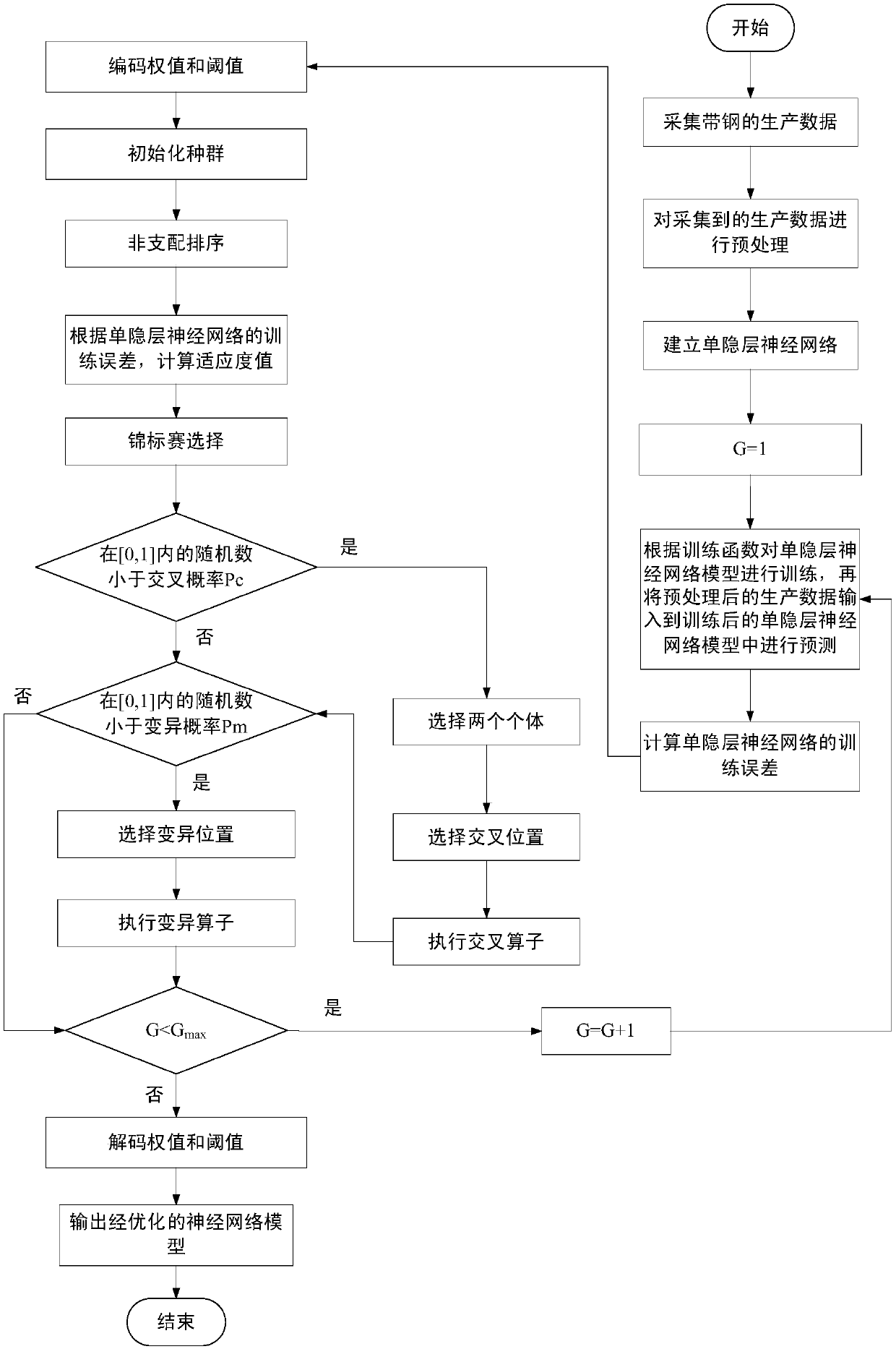

[0050] A data-driven method for predicting the crown of hot-rolled strips, the process is as follows figure 2 shown, including the following steps:

[0051] Step 1: Collect the production data of strip steel, including coil number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com