A Fabry-Perot Antenna with High Gain and Low Radar Cross Section

A radar cross-section, high-gain technology, applied in the field of communication antennas and missile antennas, high-gain, low radar cross-section Fabry-Perot antennas, can solve the problems of poor gain enhancement effect and poor radar cross-section reduction effect, and achieve reduction Metal strip structure, optimize the overall structure, overcome the effect of complex structures around reflective surfaces and radiating antennas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

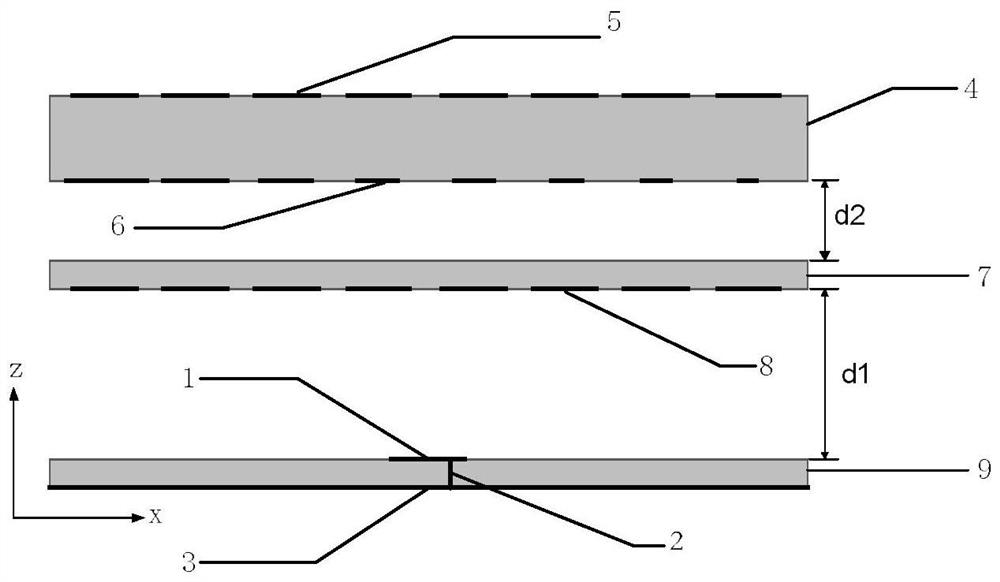

[0031] refer to figure 1 , figure 2 , image 3 and Figure 4 ,

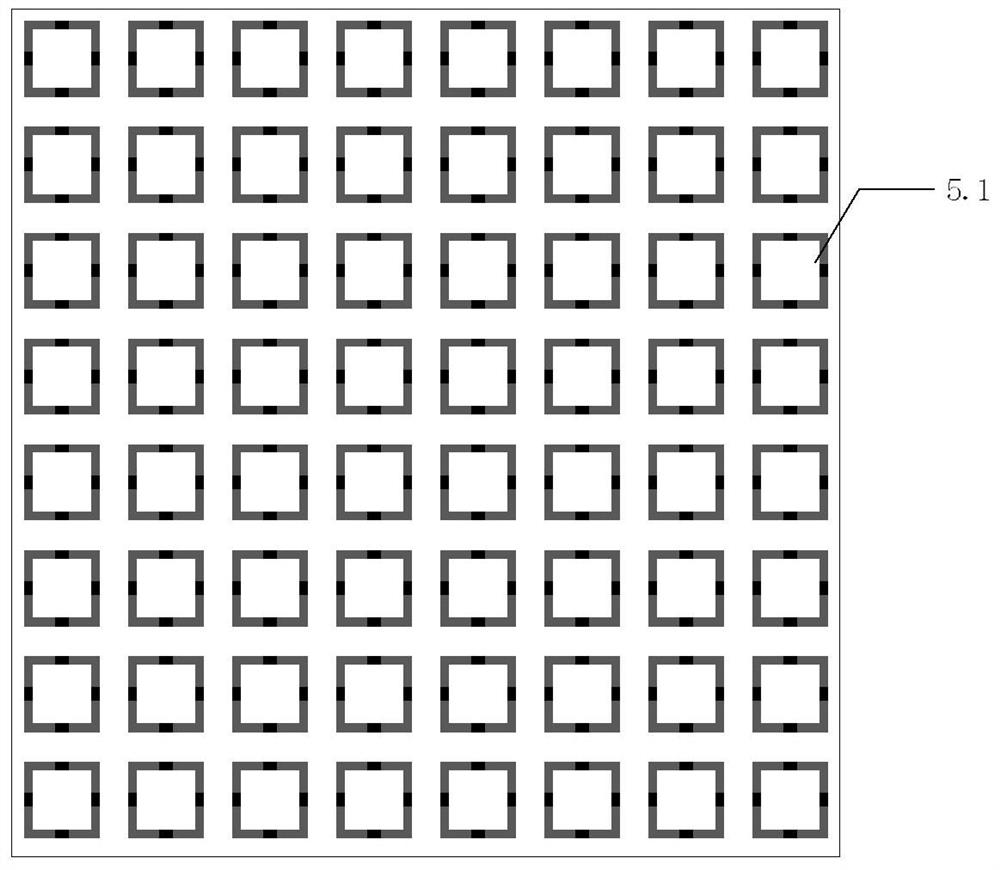

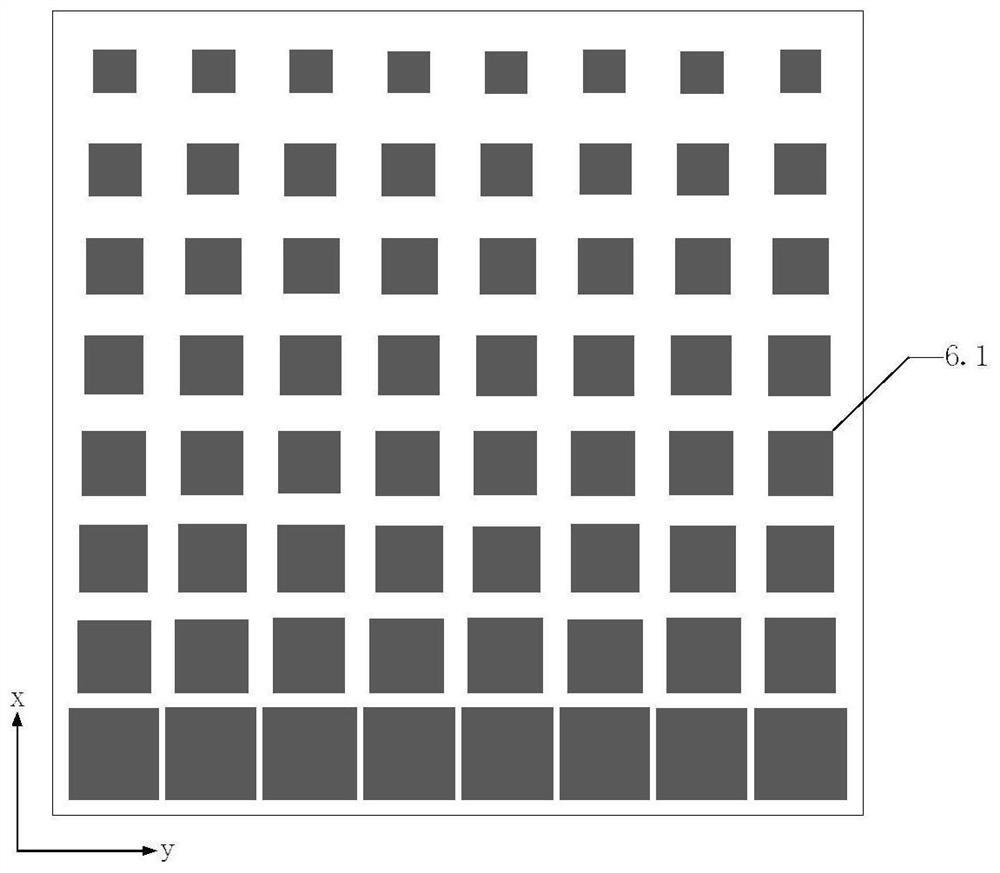

[0032] A Fabry-Perot antenna with high gain and low radar cross section, comprising an antenna radiator 1, a feed structure 2, a metal floor 3, and a first wave-absorbing coating printed on the upper and lower surfaces of a first dielectric substrate 4 5. The second reflective coating 6 and the third reflective coating 8 printed on the lower surface of the second dielectric substrate 7; the antenna radiator 1 is printed on the upper surface of the third dielectric substrate 9, and the feeding structure 2 Penetrating through the third dielectric substrate 9 and connected to the antenna radiator 1 and the metal floor 3, the first wave-absorbing cladding 5 is distributed in a checkerboard pattern, and consists of N×N square absorbers with the same structure periodically arranged Composed of unit 5.1, wherein, N≥2, N is a positive integer, each square absorbing unit 5.1 is a metal ring structure, and the four si...

Embodiment 2

[0045] This embodiment has the same structure as Embodiment 1, only the following parameters are adjusted:

[0046] refer to figure 1

[0047] The thickness of the air layer between the second dielectric substrate and the third dielectric substrate is d1, d1=10mm, the thickness of the air layer between the first dielectric substrate and the second dielectric substrate is d2, d2=0.2mm

[0048] refer to Figure 5

[0049] Square metal ring patch unit 8.1, when the outer length is Wout=9mm, the width of the metal ring is Ws, Ws=2mm. The side length of the square metal patch unit is Wm=2mm, the side length of the square metal ring on the square absorbing unit 5.1 is a=3mm, and the width of the metal ring is W1=0.1mm.

Embodiment 3

[0051] This embodiment has the same structure as Embodiment 1, only the following parameters are adjusted:

[0052] refer to figure 1

[0053] The thickness of the air layer between the second dielectric substrate and the third dielectric substrate is d1, d1=26mm, the thickness of the air layer between the first dielectric substrate and the second dielectric substrate is d2, d2=1.8mm

[0054] refer to Figure 5

[0055] Square metal ring patch unit 8.1, when the outer side length is Wout=17mm, the width of the metal ring is Ws, Ws=6mm. The side length Wm=17mm of the square metal patch unit, the side length a=9mm of the square metal ring on the square absorbing unit 5.1, the width of the metal ring is W1, W1=1.1mm.

[0056] Below in conjunction with accompanying drawing and the present invention will be further described

[0057] Simulation content and conditions

[0058] refer to Figure 7 , the present invention simulates the antenna in Embodiment 1 through the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com