Method for producing closure in container made of plastic

A technology for sealing parts and containers, which can be used to close containers tightly with lids, closures, medical containers, etc. It can solve the problems of thermal decomposition of plastics, the inability to reduce the number of bacteria, toxic decomposition products and gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

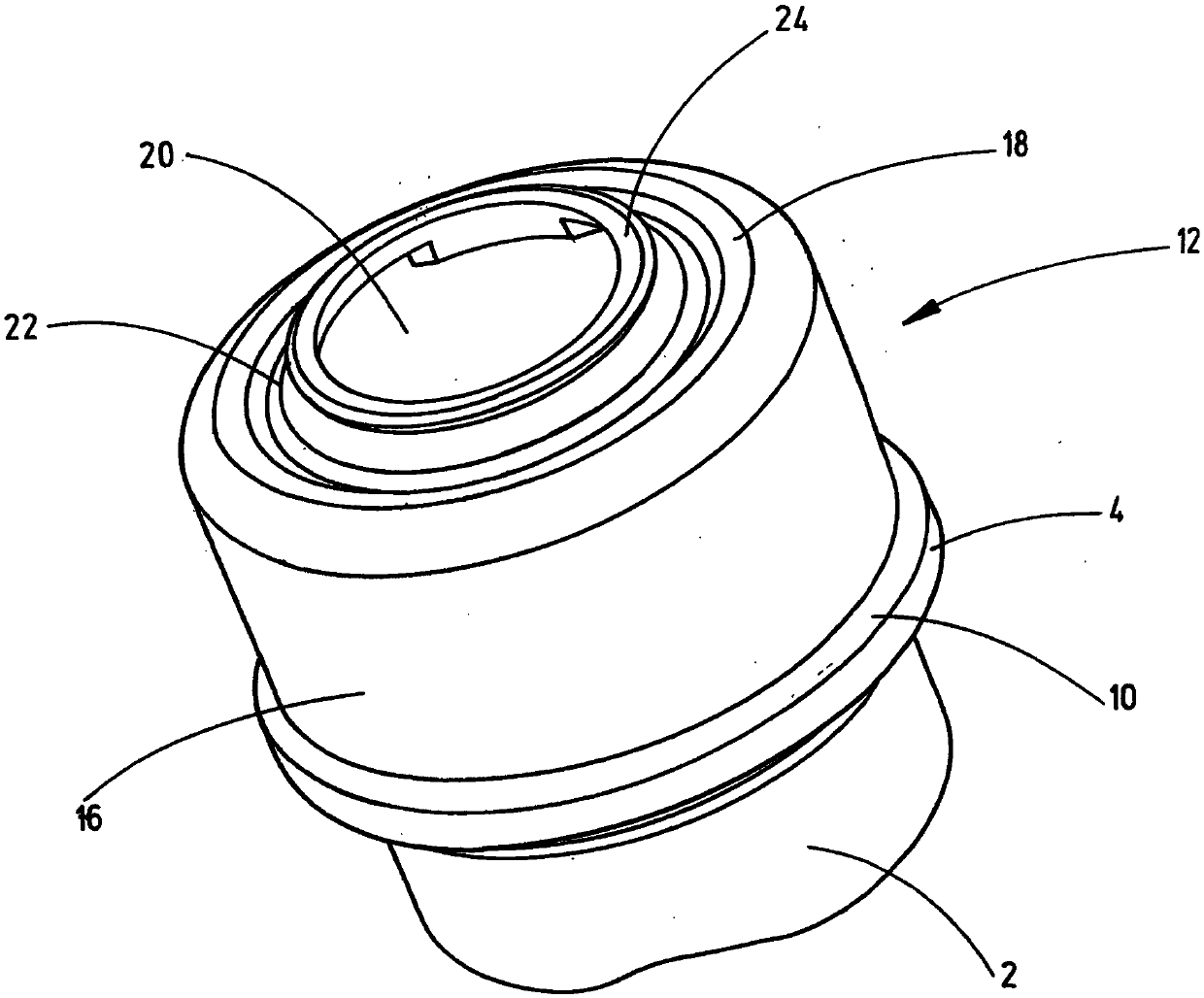

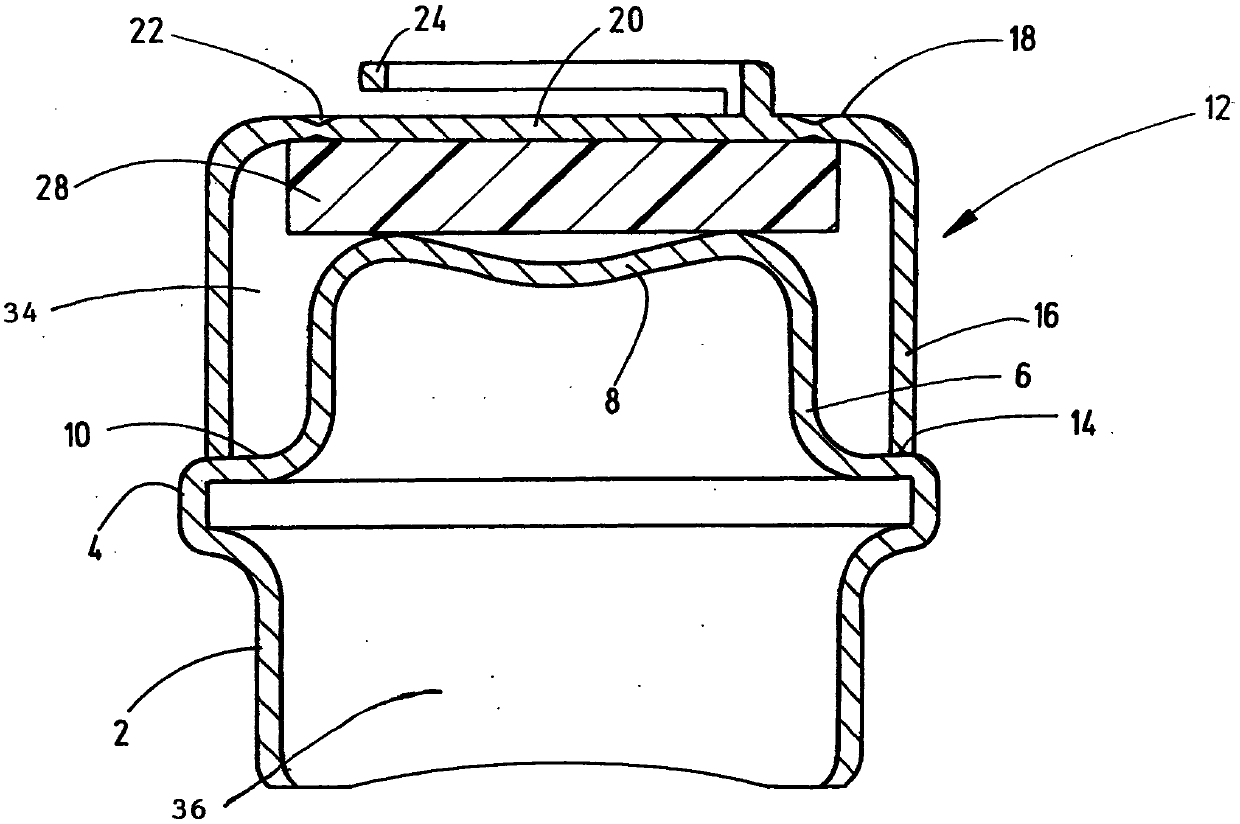

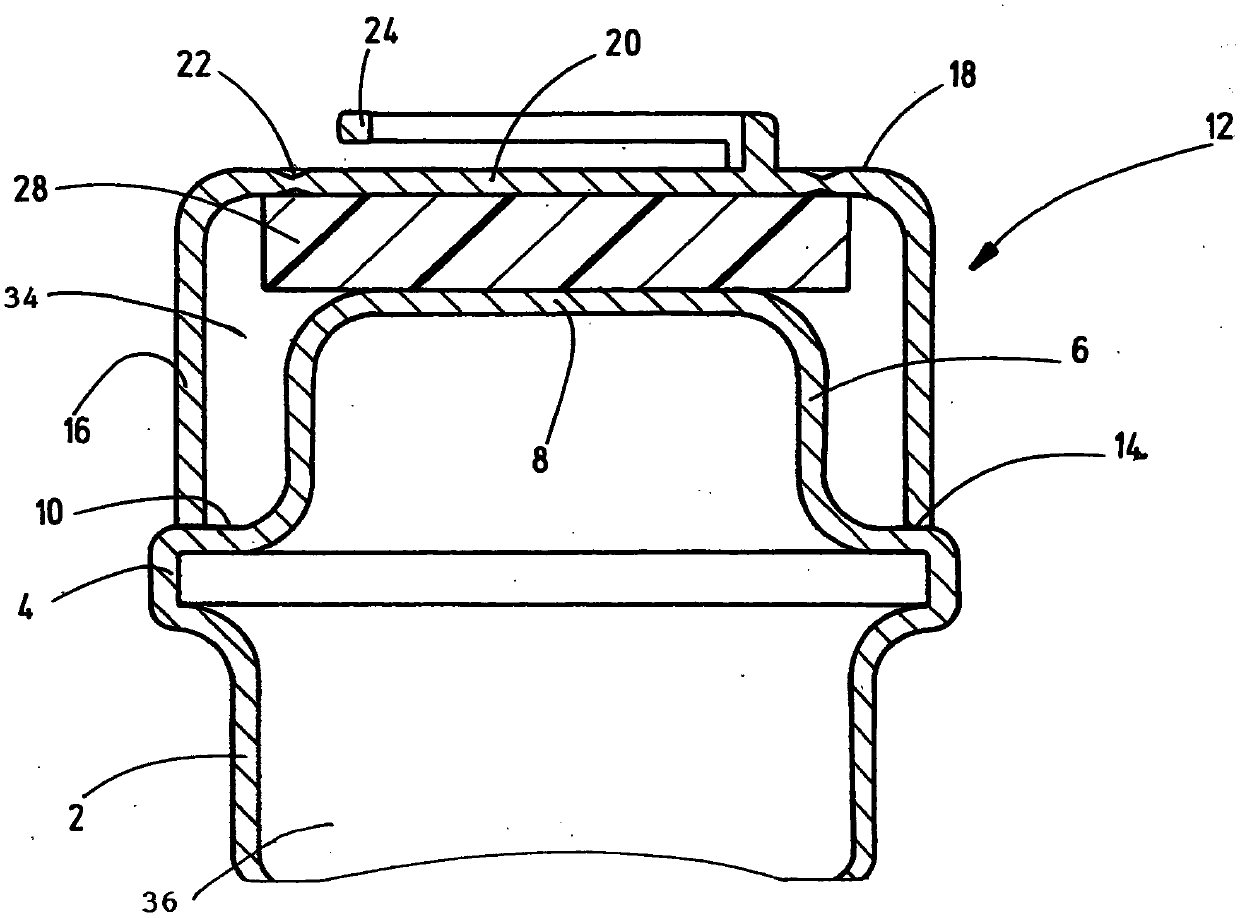

[0033] A closure cap 12 of type A according to ISO 15759:2005 is fitted onto the flange of a filled and closed infusion container according to DIN EN ISO 15747 produced according to the blow fill seal method (BFS). The closure cap 12 has been connected by welding to the edge 14 of the container neck 2 in a pressure- and micro-organism-tight manner. The sealing material 28 consists of an elastomer sheet inserted into the cover 12, the elastomer sheet being manufactured by ELASTO 500300M, the infusion container is made of polypropylene Bormed SB 815 MO from Borealis. After the closing cap has been fitted, the sealing material 28 rests non-adhesively on the membrane formed by the container wall part 8 . After an autoclave process in a support pressure autoclave from the Bosch company at a temperature of 121° C. and a holding time of 20 minutes at this temperature, the housing of the closing cap 12 has been destructively removed and the measuring The force required to peel off ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com