Textile sheet material, its use and cleaning device comprising the textile sheet material

A compositional and surface-based technology, applied in cleaning devices, transportation and packaging, applications, etc., can solve problems such as complex connections, weakened fabric composites, supply and operation accuracy of a single layer, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

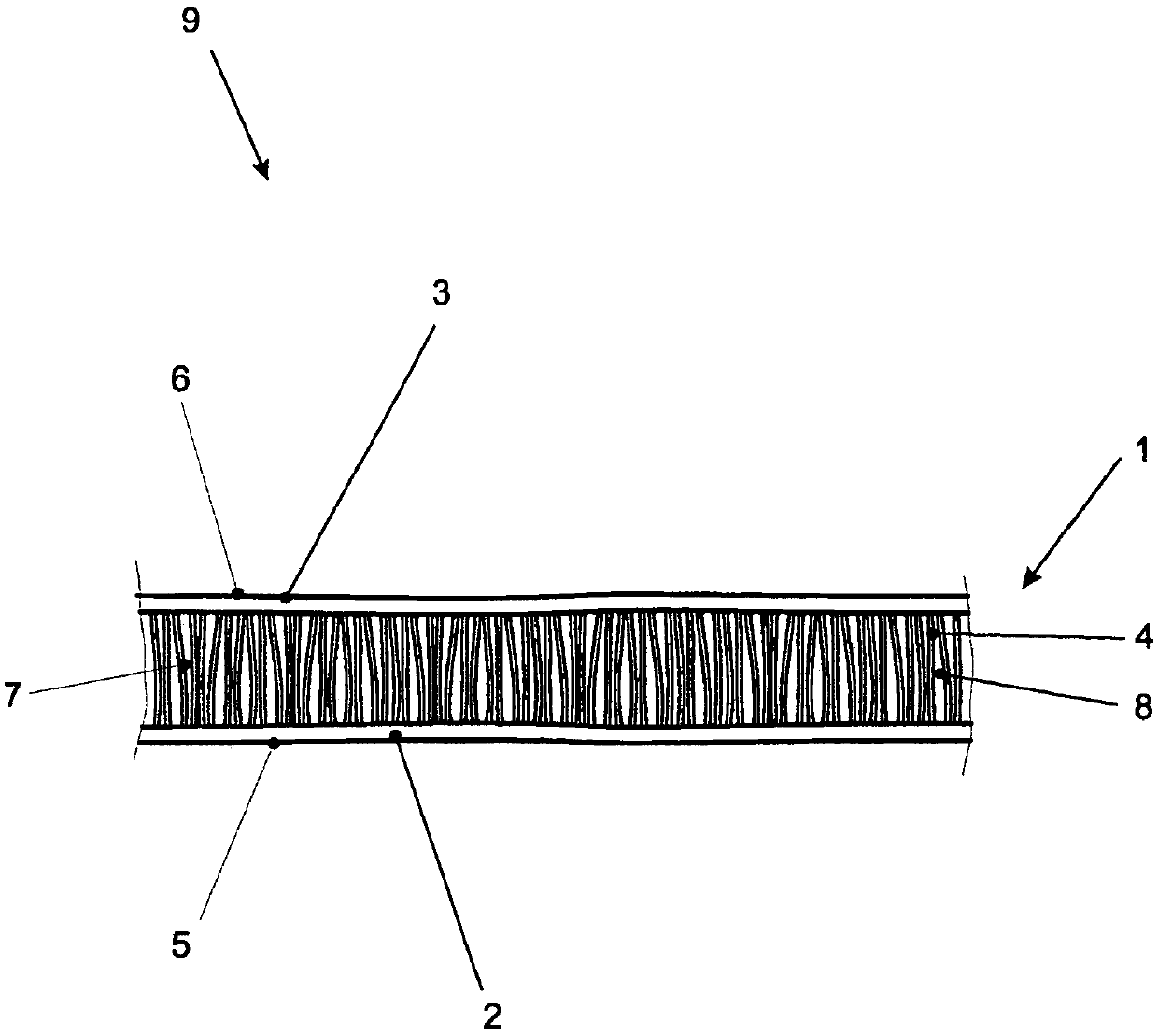

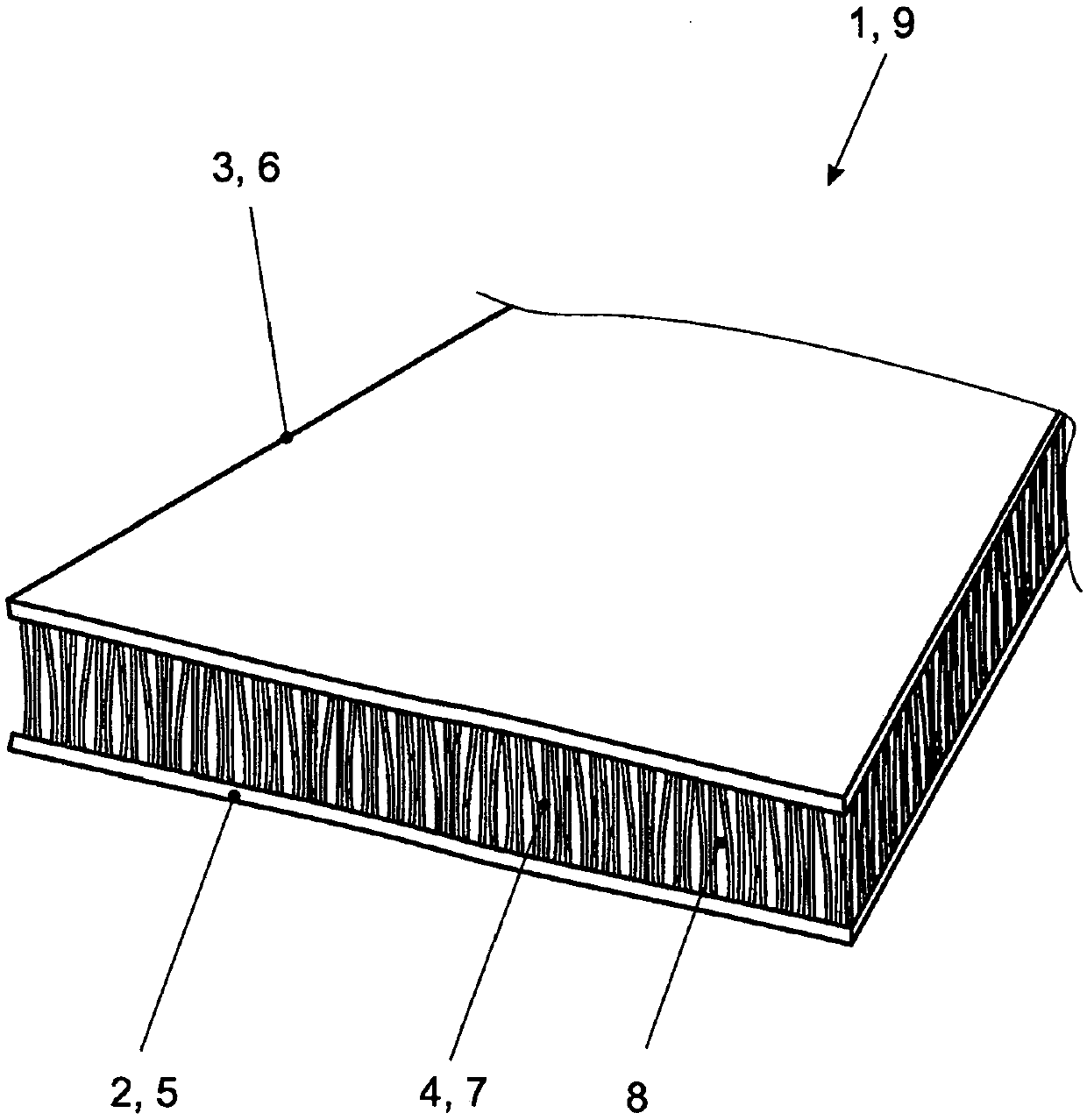

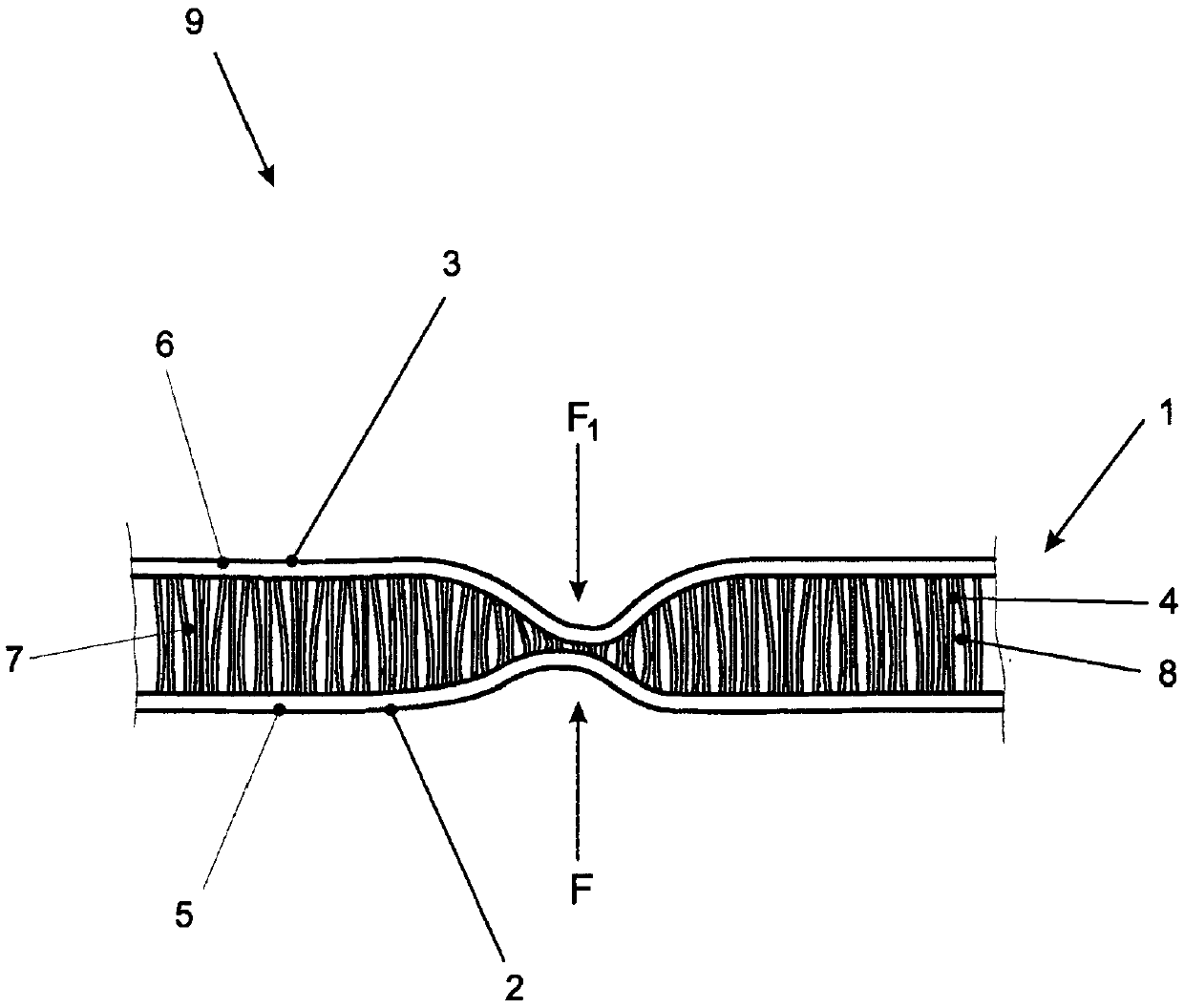

[0025] exist Figures 1 to 4 One embodiment of the textile surface structure according to the present invention is shown in FIG.

[0026] figure 1 The textile surface structure is shown in cross-section. The textile fabric structure comprises a layered structure 1 which has two outer layers 2 , 3 which are separated from each other by an intermediate layer 4 and connected to each other in a non-detachable manner by means of the intermediate layer 4 .

[0027] One outer side 2 is designed as a cleaning layer 5 and the other outer layer 3 is designed as a dimensionally stabilizing support layer 6 for the textile surface structure. The intermediate layer 4 is formed as a spacer layer 7 .

[0028] The textile surface formation is used as a cleaning fabric 9 in a cleaning device, such as Figure 5 as shown in.

[0029] The cleaning layer 5 can be formed by conventional cleaning fabrics and comprises microfibres, for example.

[0030] The support layer 6 serves to stabilize t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com