A kind of preparation method of graphene oxide modified microporous molecular sieve shape selective catalyst

A microporous molecular sieve and graphene modification technology, which is applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high cost, low catalytic efficiency, cumbersome preparation and operation of shape-selective catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

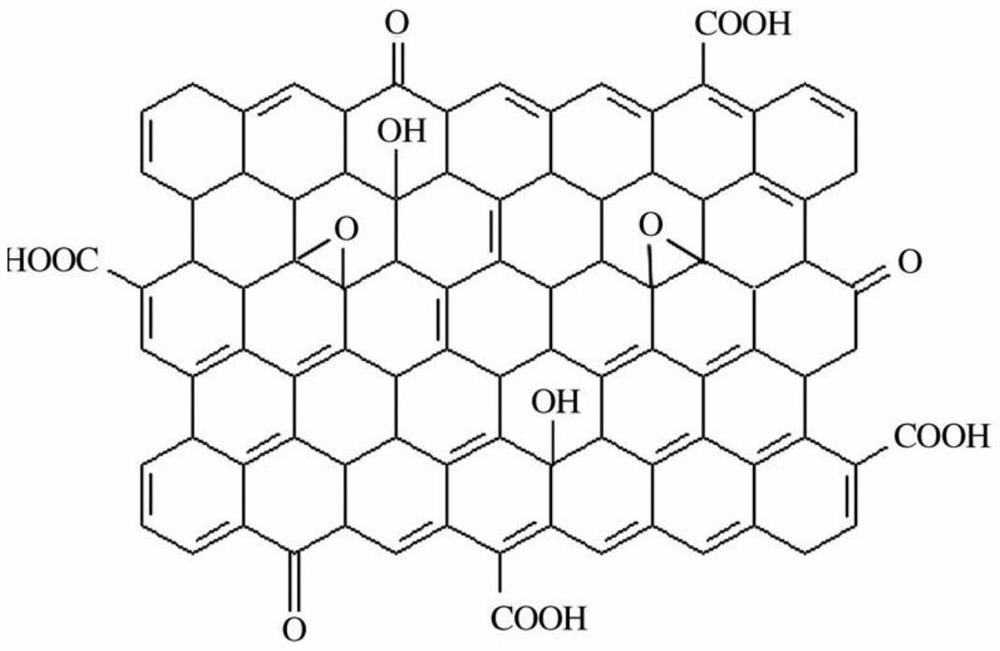

Method used

Image

Examples

Embodiment 1

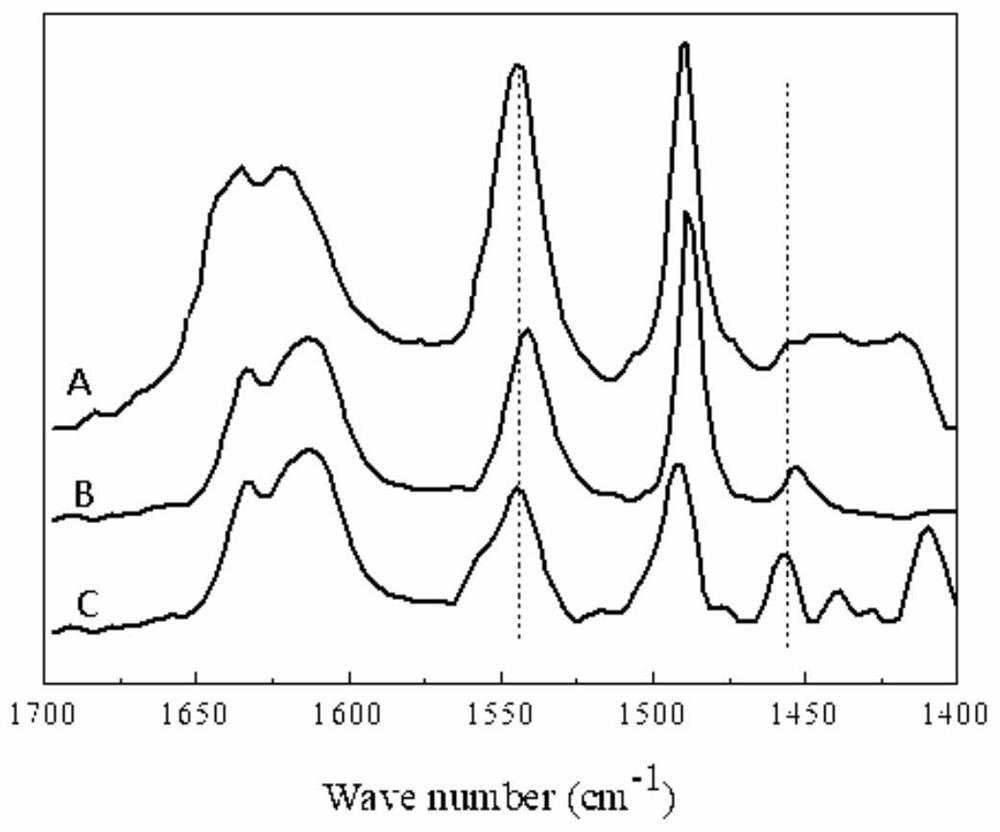

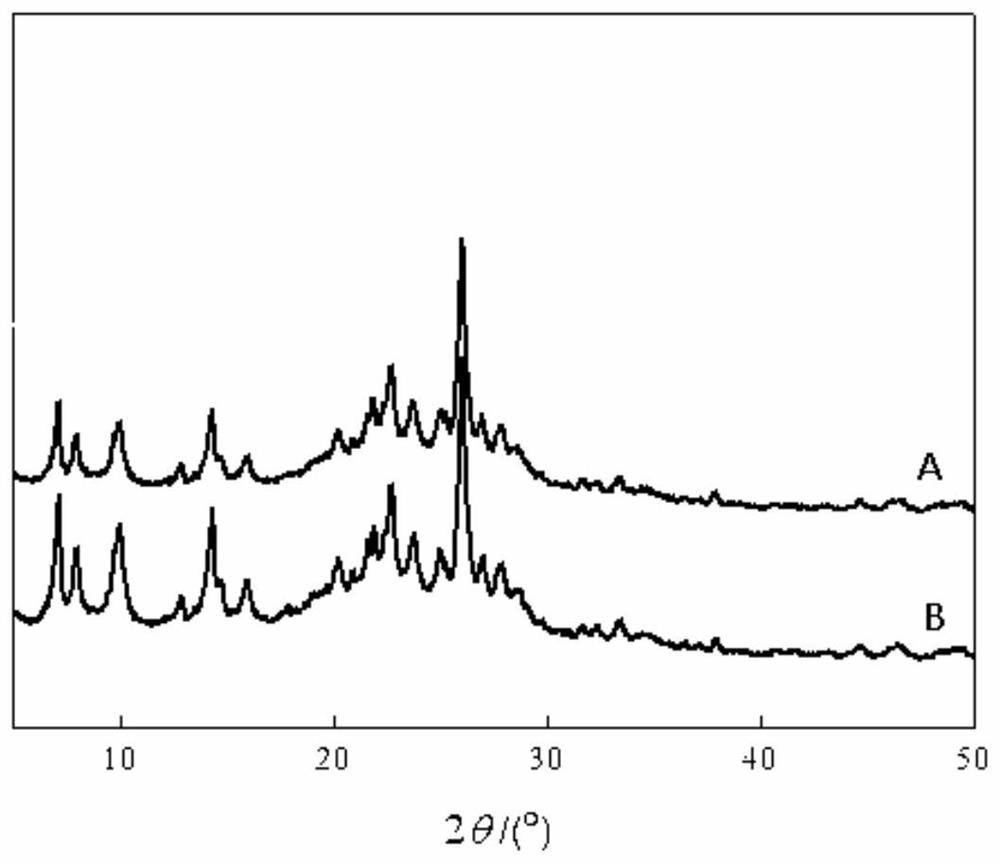

[0031] Add 2g of microporous molecular sieve MCM-22 to 40mL of deionized water, and ultrasonically disperse for 30min at room temperature; add 0.2g of graphene oxide to 10mL of deionized water, and disperse by ultrasonic for 30min at room temperature; drop the graphene oxide dispersion under ultrasonic conditions Add to the dispersion of the microporous molecular sieve, and then sonicate for 30 minutes after the addition is complete; filter the mixture obtained in the above process, and dry the filter cake at 80°C for 12 hours, then increase the temperature to 120°C and keep it at this temperature for 2 hours, Then it is cooled down to room temperature to obtain the desired graphene oxide modified microporous molecular sieve shape-selective catalyst, which is recorded as Cat1.

Embodiment 2

[0033] Add 2g of microporous molecular sieve MCM-22 to 60mL of deionized water, and ultrasonically disperse for 30min at room temperature; add 0.2g of graphene oxide to 14mL of deionized water, and disperse by ultrasonic for 30min at room temperature; drop the graphene oxide dispersion under ultrasonic conditions Add to the dispersion of the microporous molecular sieve, and then sonicate for 30 minutes after the addition is complete; filter the mixture obtained in the above process, and dry the filter cake at 80°C for 12 hours, then increase the temperature to 120°C and keep it at this temperature for 2 hours, Then it is cooled to room temperature to obtain the desired graphene oxide modified microporous molecular sieve shape-selective catalyst, denoted as Cat2.

Embodiment 3

[0035] Add 2g of microporous molecular sieve MCM-22 to 100mL of deionized water, and ultrasonically disperse for 30min at room temperature; add 0.3g of graphene oxide to 30mL of deionized water, and then ultrasonically disperse for 30min at room temperature; drop the graphene oxide dispersion under ultrasonic conditions Add to the dispersion of the microporous molecular sieve, and then sonicate for 30 minutes after the addition is complete; filter the mixture obtained in the above process, and dry the filter cake at 80°C for 12 hours, then increase the temperature to 120°C and keep it at this temperature for 2 hours, Then the temperature is lowered to room temperature, and the desired graphene oxide modified microporous molecular sieve shape-selective catalyst is obtained, which is recorded as Cat3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com