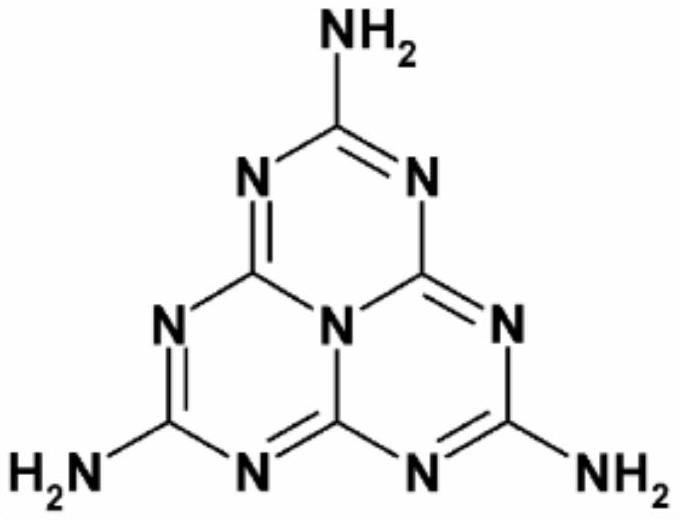

A kind of preparation method of melem modified microporous molecular sieve shape-selective catalyst

A technology of microporous molecular sieve and melem, which is applied in the field of preparation of shape-selective catalysts, can solve the problems of high cost, low catalytic efficiency, complicated preparation and operation of shape-selective catalysts and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

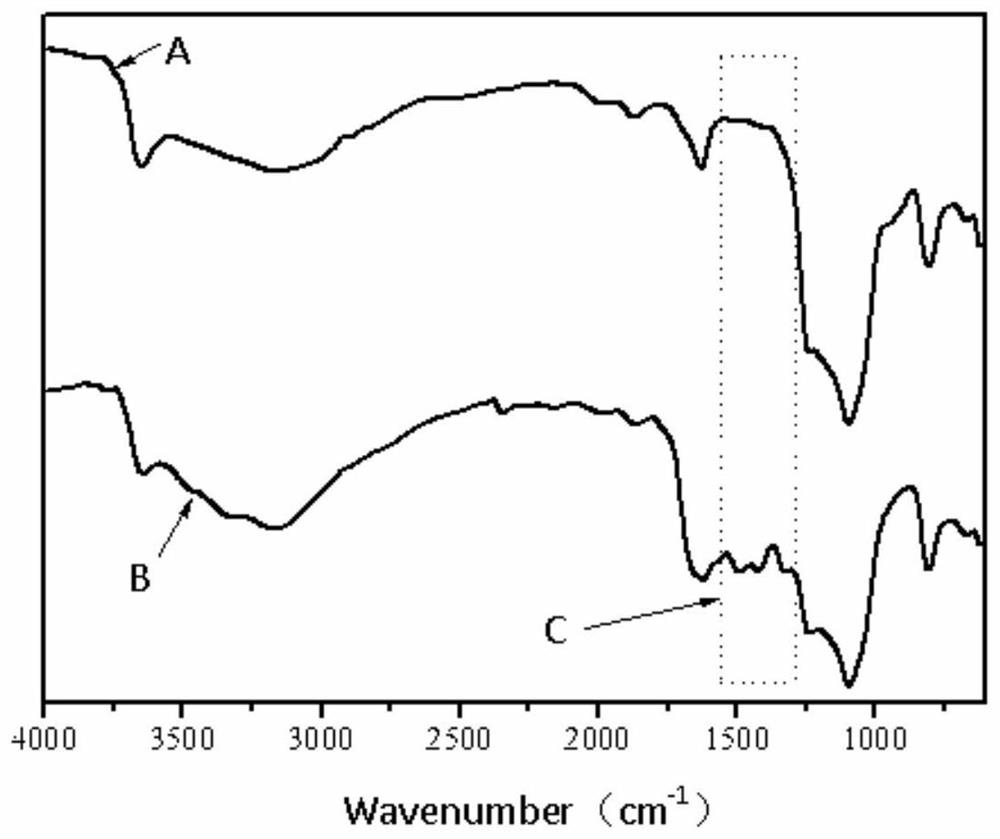

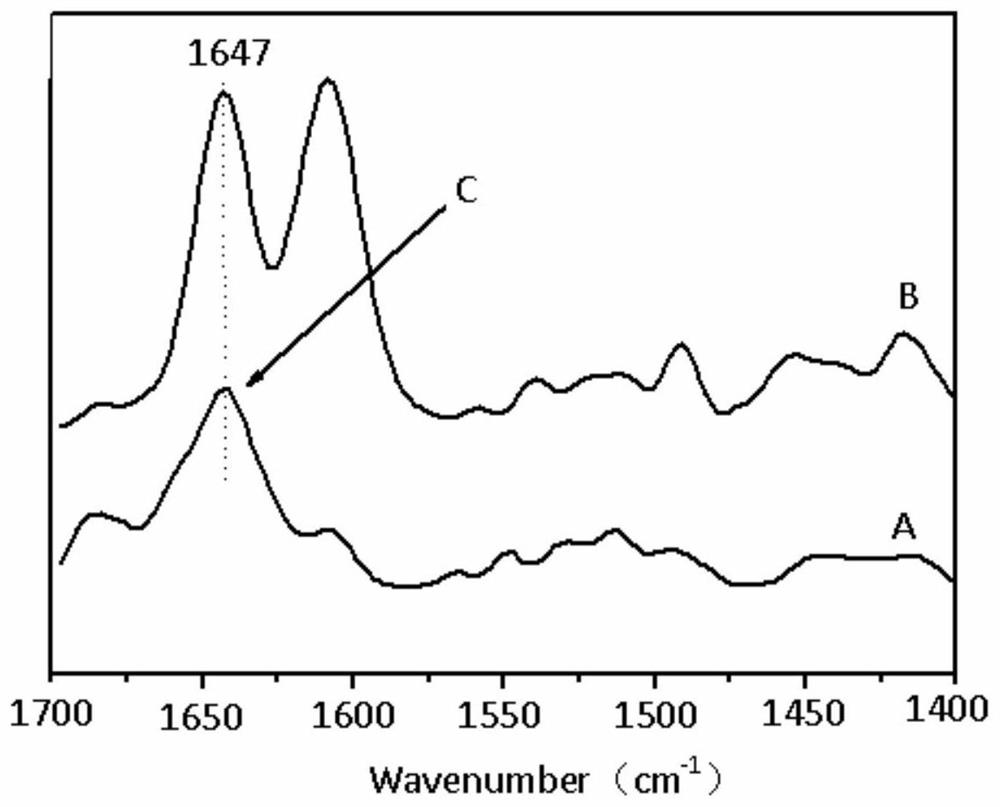

[0027] Add 2g of microporous molecular sieve MCM-22 into 40mL of deionized water, and disperse by ultrasonic at room temperature for 30min; add melem powder gradually to the above mixture, add 0.02g each time, add 5 times continuously, and ultrasonicate for 30min after each addition ; Then filter the resulting mixture, dry the filter cake at 80°C for 12h, then raise the temperature to 120°C, and keep it at this temperature for 2h, and then lower it to room temperature to obtain the desired melem modified microporous molecular sieve Shape-selective catalysts are denoted as Cat1.

Embodiment 2

[0029] Add 2g of microporous molecular sieve MCM-22 into 100mL of deionized water, and disperse by ultrasonic at room temperature for 30min; add melem powder gradually to the above mixture, add 0.02g each time, add 10 times continuously, and ultrasonicate for 30min after each addition ; Then filter the resulting mixture, dry the filter cake at 80°C for 12h, then raise the temperature to 120°C, and keep it at this temperature for 2h, and then lower it to room temperature to obtain the desired melem modified microporous molecular sieve Shape-selective catalysts are denoted as Cat2.

Embodiment 3

[0031] Add 2g of microporous molecular sieve MCM-22 into 60mL of deionized water, and disperse by ultrasonic at room temperature for 30min; add melem powder gradually to the above mixture, add 0.02g each time, add 7 times continuously, and ultrasonicate for 30min after each addition ; Then filter the resulting mixture, dry the filter cake at 80°C for 12h, then raise the temperature to 120°C, and keep it at this temperature for 2h, and then lower it to room temperature to obtain the desired melem modified microporous molecular sieve Shape-selective catalysts are denoted as Cat3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com