Method for preparing gradient material by stirring friction welding and prepared gradient material

A gradient material and friction stir technology, applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve the problems of low production efficiency, high equipment cost, large pollution, etc., and achieve the effect of realizing continuous gradient materials and enriching preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] What this embodiment prepares is 70%Al-30%Al 2 o 3 / 6061 aluminum alloy gradient material. Concrete preparation steps are as follows:

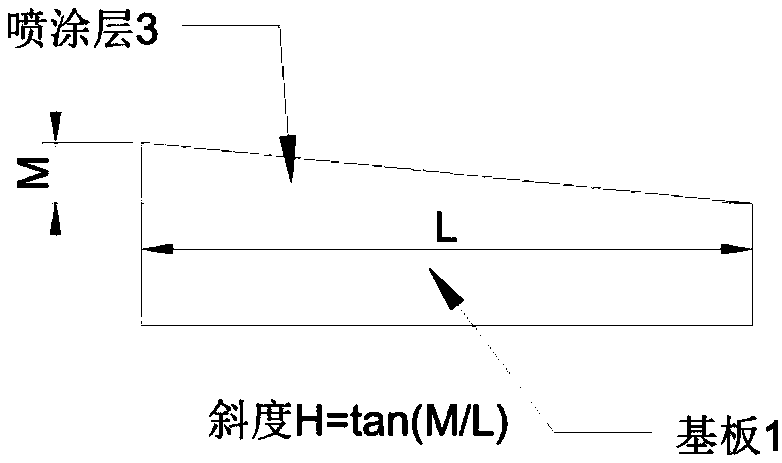

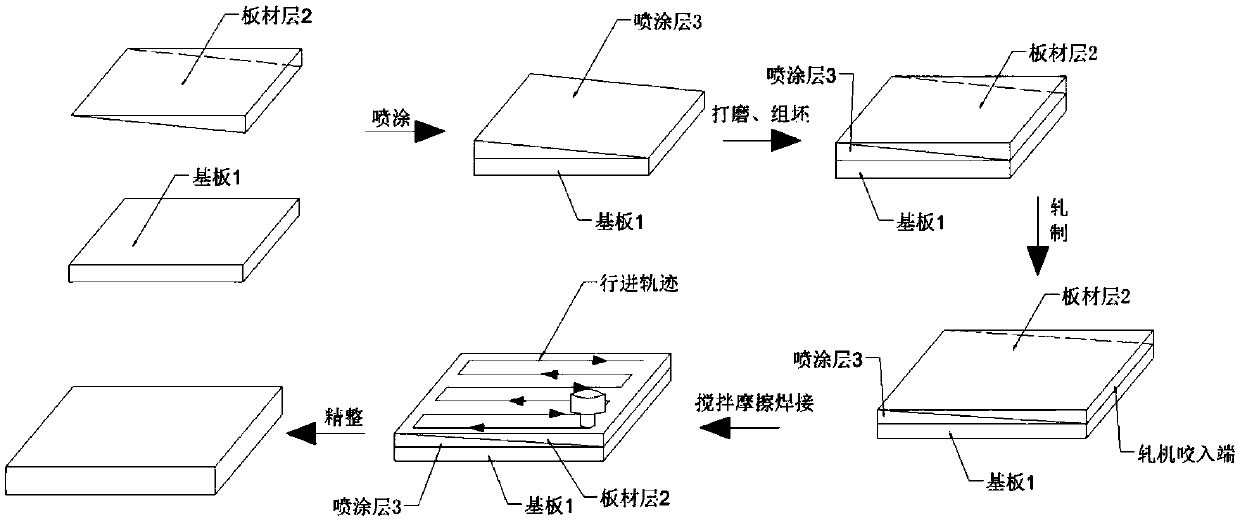

[0057] Raw material selection and pretreatment: Select a 6061 aluminum alloy plate with a size of 100mm×90mm×3mm and a wedge-shaped 6061 aluminum alloy plate with a size of 100mm×90mm×3mm with a slope of H=0.05, and use sandpaper to sand the two aluminum alloys. The surface of the alloy plate is polished smooth, and the surface is cleaned with acetone and air-dried. The size of the sprayed layer is 100mm×90mm×3mm, and the composition is 70%Al-30%Al 2 o 3 .

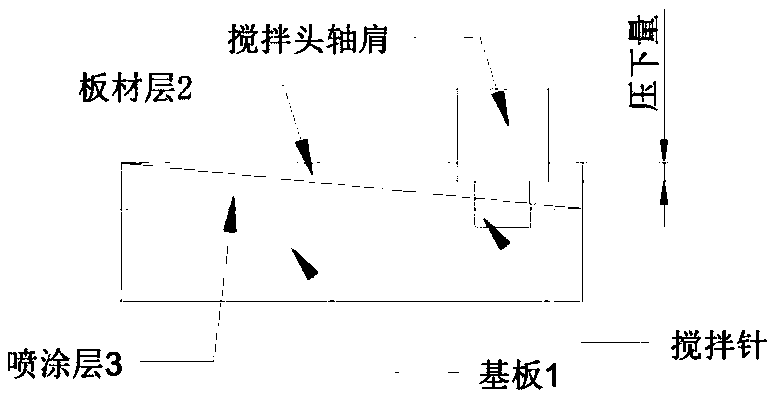

[0058] Raw material selection of the processing device: the material of the processing device is high-speed steel (W18Cr4V), the diameter of the shaft shoulder is 15 mm, the diameter of the cylindrical stirring needle is 5 mm, and the length is 5.5 mm.

[0059] Processing parameter settings: the rotation speed of the friction stir welding is 950rpm, the forward speed is 37.5mm...

Embodiment 2

[0065] This example prepares a 70% Ti-30% SiC / AZ31 magnesium alloy gradient material. Concrete preparation steps are as follows:

[0066] Raw material selection and pretreatment: AZ31 magnesium alloy plate with a size of 100mm×70mm×4mm and a wedge-shaped AZ31 magnesium alloy plate with a slope of H=0.075 with a size of 100mm×70mm×4mm were respectively selected. Use sandpaper to smooth the surface of two AZ31 magnesium alloy plates, clean the surface with acetone, and air dry. The size of the sprayed layer is 100mm×70mm×6mm, and the composition is 70%Ti-30%SiC.

[0067] Raw material selection of the processing device: The material of the processing device is XF20T tungsten steel, the diameter of the shaft shoulder is 16mm, the diameter of the cylindrical stirring needle is 5mm, and the length is 6.5mm.

[0068] Processing parameter setting: the rotation speed of the friction stir welding is 1180rpm, the forward speed is 30mm / min, and the reduction is 0.2mm.

[0069] specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com