Intelligent control flexible rack

An intelligent control and flexible technology, applied in grinding frames, manufacturing tools, grinding machine parts, etc., can solve problems such as inability to guarantee operation accuracy, injury accidents, etc., and achieve the effect of safe use and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

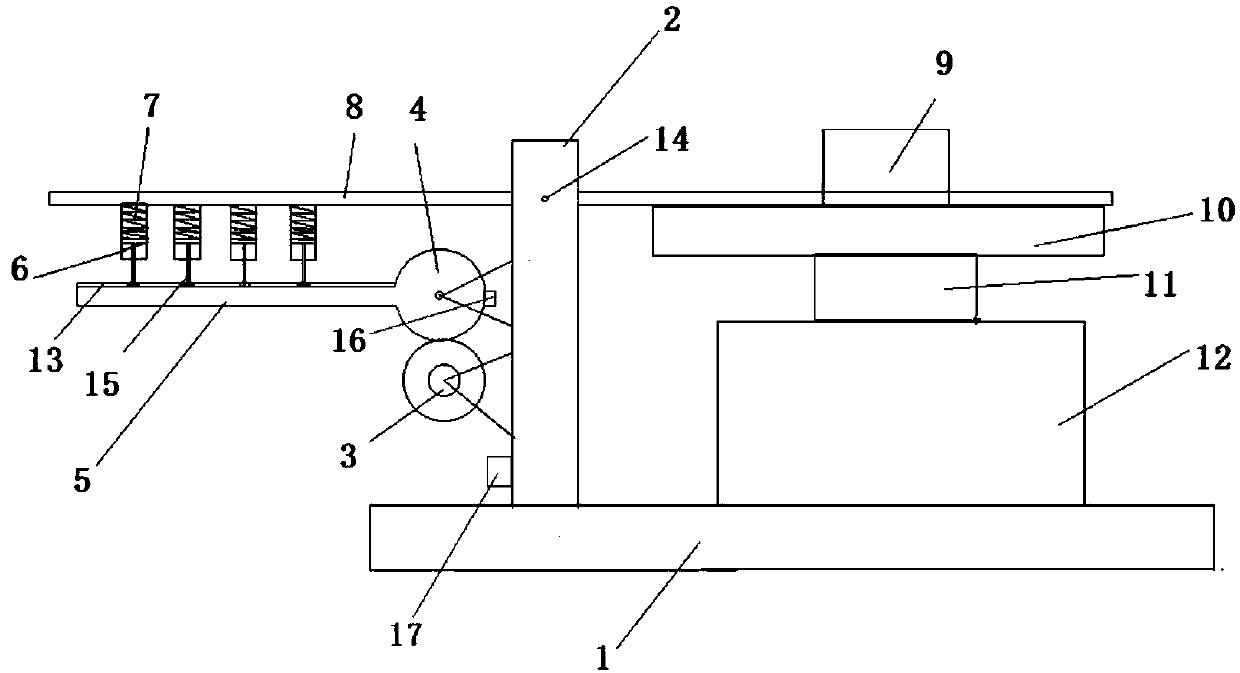

[0010] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, the present invention includes a base 1, a support 2 is set on the base 1, a workpiece support 12, and a workpiece 11 is placed on the workpiece support 12; the support 2 is connected to the crossbeam 8 through a rotating shaft 14; one end of the crossbeam 8 A balance device is set, and a rotary motor 9 is set on the crossbeam at the other end, and the polishing wheel 10 under the crossbeam driven by the rotary motor 9 rotates; the balance device includes an extension spring 7, and one end of the extension spring 7 is fixed on the crossbeam 8, The other end is connected with the piston ring 6, and the piston ring 6 is slidingly connected with the elongated groove 13 on the driving arm 5 through the pull rod 15; the end of the driving arm 5 is fixed with the driving wheel 4, and the driving wheel 4 is meshed with the motor output wheel 3; Wheel 4 and moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com